This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

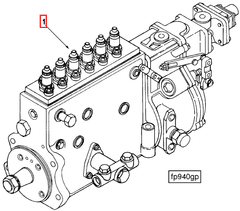

The Cummins 3921083 Fuel Injection Pump is a component designed for use in commercial trucks. It is integral to the operation of these vehicles, facilitating the precise delivery of fuel to the engine. This pump ensures that the engine receives the correct amount of fuel at the right time, which is vital for efficient combustion and overall engine performance 4.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps operate on the principle of delivering pressurized fuel to the engine’s combustion chambers. In diesel engines, these pumps play a role in atomizing the fuel, which enhances combustion efficiency. The pump works in conjunction with the engine’s timing mechanism to ensure that fuel is injected at the optimal moment in the engine cycle 1.

Purpose of the Cummins 3921083 Fuel Injection Pump

The Cummins 3921083 Fuel Injection Pump serves to deliver fuel from the tank to the engine’s cylinders. It does this by pressurizing the fuel and injecting it into the combustion chamber at precise intervals. This function is crucial for maintaining the engine’s power output and fuel efficiency. The pump’s ability to deliver fuel with accuracy and consistency directly influences the engine’s performance and emissions 2.

Key Features

The Cummins 3921083 Fuel Injection Pump is characterized by several key features. Its design incorporates advanced materials that enhance durability and resistance to wear. The pump utilizes precise engineering to ensure accurate fuel delivery. Additionally, it incorporates technological advancements that improve its efficiency and reliability. These features contribute to the pump’s ability to operate under the demanding conditions typical of commercial truck applications 3.

Benefits

The Cummins 3921083 Fuel Injection Pump offers several benefits. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the engine in the most effective manner. This results in better overall engine performance and reduced fuel consumption. The pump’s reliable operation also enhances the truck’s dependability, which is critical for commercial operations 4.

Installation Process

Installing the Cummins 3921083 Fuel Injection Pump requires careful attention to detail. The process involves disconnecting the old pump, ensuring the fuel system is clean and free of contaminants, and then fitting the new pump. Proper tools and precautions, such as using the correct torque settings and ensuring all connections are secure, are necessary to complete the installation successfully 1.

Common Issues and Troubleshooting

Common issues with the Cummins 3921083 Fuel Injection Pump may include fuel delivery inconsistencies or pump failure. Troubleshooting these issues often involves checking for fuel system leaks, ensuring the pump is receiving adequate power, and verifying that the pump’s timing is correctly set. Regular inspections and maintenance can help prevent many of these issues 2.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3921083 Fuel Injection Pump, regular maintenance is recommended. This includes periodic inspections for wear and tear, cleaning or replacing fuel filters, and ensuring that the pump is free of contaminants. Adhering to the manufacturer’s maintenance schedule will help maintain the pump’s efficiency and reliability 3.

Performance Enhancements

For those looking to enhance the performance of their Cummins 3921083 Fuel Injection Pump, there are several options available. Upgrading to a higher-performance pump or modifying the fuel system can result in improved engine output and efficiency. It is important to consult with a professional to ensure that any enhancements are compatible with the truck’s engine and fuel system 4.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, with a strong reputation for producing diesel engines and components. The company has a history of innovation and quality, which is reflected in its products, including the Cummins 3921083 Fuel Injection Pump. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the commercial truck industry 1.

Role of Part 3921083 Fuel Injection Pump in Engine Systems

The part 3921083 Fuel Injection Pump is integral to the efficient operation of engine systems, working in concert with several key components to ensure optimal performance.

Interaction with the Base Fuel Pump

The Base Fuel Pump serves as the initial stage in the fuel delivery process, drawing fuel from the tank and delivering it to the Fuel Injection Pump. The Base Fuel Pump maintains a consistent fuel pressure, which is essential for the Fuel Injection Pump to function correctly. The Fuel Injection Pump then takes over, precisely metering and injecting fuel into the engine’s combustion chambers at the exact moment required for efficient combustion 2.

Coordination with Fuel Injectors

Once the Fuel Injection Pump has pressurized the fuel, it is distributed to the Fuel Injectors. These injectors are responsible for spraying atomized fuel into the engine cylinders. The precision timing and pressure regulated by the Fuel Injection Pump ensure that the fuel injectors operate efficiently, leading to better fuel economy and reduced emissions 3.

Synergy with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) plays a significant role in monitoring and adjusting the operation of the Fuel Injection Pump. By receiving data from various sensors, the ECU can fine-tune the injection timing and fuel quantity, optimizing engine performance under different operating conditions. The Fuel Injection Pump responds to these commands, adjusting its operation to meet the demands placed on the engine 4.

Integration with the High-Pressure Fuel System

The High-Pressure Fuel System relies on the Fuel Injection Pump to maintain the necessary pressure levels for efficient fuel delivery. This system includes components such as the fuel rail and pressure regulator, all of which depend on the consistent and precise operation of the Fuel Injection Pump to function correctly 1.

Contribution to the Common Rail System

In engines equipped with a Common Rail Fuel System, the Fuel Injection Pump is responsible for maintaining the high-pressure fuel reservoir. This system allows for more flexible and precise fuel injection, enhancing overall engine performance and emissions control. The pump ensures that the common rail is always pressurized, ready to deliver fuel when needed 2.

Support for the Turbocharger

In turbocharged engines, the Fuel Injection Pump must work in harmony with the Turbocharger to maintain the correct air-fuel ratio. As the turbocharger increases the amount of air entering the engine, the Fuel Injection Pump must deliver a corresponding increase in fuel to maintain optimal combustion. This balance is essential for maximizing power output while ensuring efficient operation 3.

Collaboration with the Exhaust Gas Recirculation (EGR) System

The Exhaust Gas Recirculation (EGR) System relies on precise fuel delivery to function effectively. By recirculating a portion of the exhaust gases back into the intake, the EGR system reduces nitrogen oxides (NOx) emissions. The Fuel Injection Pump ensures that the fuel is delivered with the necessary precision to support the EGR system’s operation, contributing to lower emissions and improved engine efficiency 4.

Conclusion

The Cummins 3921083 Fuel Injection Pump is a critical component in the operation of commercial truck engines. Its precise fuel delivery capabilities enhance engine performance, fuel efficiency, and emissions control. Regular maintenance and proper installation are essential to ensure the longevity and reliability of this Cummins part. Understanding its role within the engine system and its interaction with other components can lead to better overall vehicle performance and efficiency.

-

George Peters and Barbara J Peters, Automobile Vehicle Safety (CRC Press, 2002).

↩ ↩ ↩ ↩ -

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems (Wiley, 2022).

↩ ↩ ↩ ↩ -

Andrew Livesey, The Repair of Vehicle Bodies (Elevier, 2000).

↩ ↩ ↩ ↩ -

Haoran Hu, Rudy Smaling, and Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014).

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.