This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

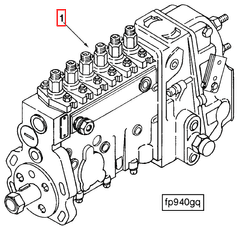

The Cummins 3925436 Fuel Injection Pump is a component designed for use in commercial trucks. It plays a role in the operation of these vehicles by ensuring the precise delivery of fuel to the engine. This pump contributes to maintaining optimal engine performance, fuel efficiency, and emissions control.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the engine at precise moments to optimize combustion. In diesel engines, the fuel injection pump is important for efficient operation. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls for more precise fuel management 1.

Purpose of the Cummins 3925436 Fuel Injection Pump

The Cummins 3925436 Fuel Injection Pump is designed to enhance the operation of a truck’s engine. It ensures that fuel is delivered at the correct pressure and timing, which contributes to engine performance, fuel efficiency, and emissions control. By providing consistent and precise fuel delivery, this pump helps maintain the engine’s power output and efficiency 2.

Key Features

The Cummins 3925436 Fuel Injection Pump features a robust design and is constructed from high-quality materials to ensure durability and reliability. It incorporates advanced technological features that enhance its performance. These features include precise fuel metering, efficient pressure regulation, and robust construction, all of which contribute to the pump’s reliability and effectiveness in demanding commercial truck applications 3.

Benefits

The Cummins 3925436 Fuel Injection Pump offers several benefits, including improved fuel economy, enhanced engine power, reduced emissions, and increased durability. By ensuring precise fuel delivery, the pump helps optimize combustion, leading to better fuel efficiency and reduced emissions. Its durable construction ensures long-term reliability, making it a valuable component for commercial truck operators 4.

Installation and Integration

Proper installation of the Cummins 3925436 Fuel Injection Pump is important for ensuring its effective operation within a truck’s engine system. It is designed to be compatible with various engine models, but it is important to follow the manufacturer’s guidelines for installation to ensure optimal performance. Correct installation procedures help prevent issues and ensure the pump operates as intended 5.

Troubleshooting and Maintenance

Common issues with the Cummins 3925436 Fuel Injection Pump may include fuel delivery problems, leaks, or performance inconsistencies. Troubleshooting steps may involve checking for proper installation, inspecting for leaks, and ensuring all connections are secure. Regular maintenance, such as periodic inspections and following recommended service procedures, helps ensure the longevity and optimal performance of the pump 1.

Performance and Efficiency

The Cummins 3925436 Fuel Injection Pump contributes to the overall performance and efficiency of the truck by ensuring precise fuel delivery. This leads to improved engine performance, better fuel economy, and reduced emissions. Real-world applications have shown that trucks equipped with this pump demonstrate significant benefits in terms of efficiency and reliability 2.

Technological Advancements

The Cummins 3925436 Fuel Injection Pump incorporates several technological advancements that improve its functionality and reliability. These innovations include enhanced fuel metering systems, improved pressure regulation, and durable construction materials. Compared to earlier models, these advancements provide better performance and reliability, making the pump a superior choice for commercial truck applications 3.

Environmental Impact

Using the Cummins 3925436 Fuel Injection Pump helps reduce harmful emissions, contributing to more sustainable trucking operations. By ensuring precise fuel delivery and efficient combustion, the pump helps minimize the release of pollutants into the environment. This makes it an environmentally friendly choice for commercial truck operators 4.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and components, with a strong reputation in the industry for innovation and quality. The company is committed to producing reliable and efficient products that meet the demanding needs of commercial truck operators. Cummins’ dedication to quality and innovation is evident in their fuel injection pumps, including the Cummins 3925436 model 5.

Compatibility

The Cummins Fuel Injection Pump part number 3925436 is a component designed to ensure the efficient and reliable operation of various Cummins engines. This part is engineered to deliver precise fuel metering, which is important for maintaining optimal engine performance and fuel economy.

Engine Compatibility

The 3925436 fuel injection pump is compatible with several Cummins engine models, including but not limited to:

- 6C8.3: This engine is known for its robust performance and reliability, often used in heavy-duty applications. The 3925436 pump is specifically designed to work seamlessly with the 6C8.3 engine, ensuring that it meets the stringent demands of its operational environment.

Grouping of Compatible Engines

The 3925436 fuel injection pump is part of a broader range of components designed to fit various Cummins engine groups. These groups are often categorized based on engine size, application, and performance characteristics. The 3925436 is particularly suited for engines that require high-pressure fuel delivery and precise timing, ensuring smooth operation and longevity.

Application in Engine Systems

In Cummins engines, the 3925436 fuel injection pump plays a role in the fuel delivery system. It is responsible for injecting fuel into the engine’s combustion chambers at the correct time and in the correct quantity. This precision is important for achieving the desired power output and fuel efficiency. The pump’s design allows it to handle the high pressures and temperatures typical of diesel engines, ensuring durability and consistent performance over time.

Importance of Proper Fitment

Ensuring that the 3925436 fuel injection pump is correctly fitted to the engine is important for maintaining engine health and performance. Incorrect installation or the use of an incompatible pump can lead to a range of issues, including reduced fuel efficiency, increased emissions, and potential engine damage. Therefore, it is important to verify compatibility and follow manufacturer guidelines when installing this component.

By understanding the compatibility and application of the 3925436 fuel injection pump, technicians and engine operators can ensure that their Cummins engines operate at peak efficiency, providing reliable performance in demanding conditions.

Role of Part 3925436 Fuel Injection Pump in Engine Systems

The Fuel Injection Pump (part 3925436) is integral to the operation of modern engine systems, ensuring precise fuel delivery to the combustion chambers. This component works in concert with several other engine components to optimize performance, efficiency, and emissions.

Integration with the Fuel System

-

Fuel Tank: The process begins with the fuel stored in the tank. The fuel pump draws this fuel and sends it through the fuel lines to the injection pump.

-

Fuel Filter: Before reaching the injection pump, the fuel passes through a fuel filter. This filter removes impurities, ensuring that only clean fuel enters the pump.

-

Fuel Injection Pump: Once clean fuel reaches the injection pump, it is pressurized. The pump then meters and delivers the fuel to the injectors at the precise moment and in the exact quantity required for optimal combustion.

Interaction with Engine Components

-

Injectors: The pressurized fuel from the pump is delivered to the injectors. These injectors atomize the fuel into a fine mist, which is then sprayed into the combustion chamber.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters such as engine speed, load, and temperature. It sends signals to the fuel injection pump to adjust the fuel delivery accordingly, ensuring efficient and smooth operation.

-

Combustion Chamber: The atomized fuel mixes with air in the combustion chamber. The spark plug (in gasoline engines) or the compression (in diesel engines) ignites the mixture, driving the piston down and producing power.

-

Exhaust System: The combustion process generates exhaust gases, which are expelled through the exhaust system. Sensors in the exhaust, such as the oxygen sensor, provide feedback to the ECU, allowing it to make real-time adjustments to the fuel injection process.

Efficiency and Performance

The fuel injection pump plays a role in enhancing engine efficiency and performance. By providing precise fuel delivery, it ensures that the engine operates within its optimal parameters, reducing fuel consumption and emissions while maximizing power output.

Conclusion

In summary, the fuel injection pump (part 3925436) is a key component in the fuel delivery system, working seamlessly with other engine components to ensure efficient and reliable engine operation. Its precise fuel delivery capabilities contribute to improved engine performance, fuel efficiency, and reduced emissions, making it a critical component for commercial truck applications.

-

Goodnight, Nicholas, and Kirk VanGelder. Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning, 2019.

↩ ↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ ↩ -

Parikyan, Tigran Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩ ↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ ↩ -

General Information. Master Repair Manual. Bulletin Number 4021433-01.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.