This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

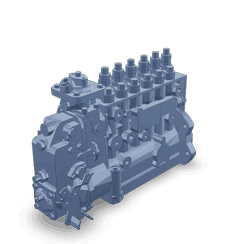

The Cummins 3926887 Fuel Injection Pump is a critical component for heavy-duty trucks, designed to optimize engine performance and efficiency by ensuring precise fuel delivery. This part is essential for the reliable operation of diesel engines in demanding applications.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, this pump ensures high-pressure fuel injection at specific intervals, contributing to smooth operation, efficiency, and minimal emissions 2. It works in conjunction with other engine components to maintain optimal performance under varying load conditions.

Role of the Cummins 3926887 Fuel Injection Pump in Truck Operation

This Cummins part precisely controls fuel delivery to the engine, ensuring optimal pressure and timing. Its operation is vital for maintaining engine power output, fuel economy, and emissions levels. The pump’s design allows it to adapt to the engine’s requirements, enhancing overall truck performance in various operational scenarios 3.

Key Features of the Cummins 3926887 Fuel Injection Pump

The 3926887 is characterized by advanced technology for precise fuel delivery, high-quality materials for durability, and technological advancements for improved efficiency and reliability. These features make it a robust component in the fuel system 4.

Benefits of Using the Cummins 3926887 Fuel Injection Pump

Utilizing this part offers improved fuel efficiency, enhanced engine performance, and reliability under demanding conditions. Its precise operation ensures consistent power output and smooth operation, contributing to overall operational efficiency 1.

Troubleshooting Common Issues with Fuel Injection Pumps

Common issues with fuel injection pumps may include irregular engine operation, decreased fuel efficiency, or increased emissions. These can arise from clogged fuel filters, worn pump components, or incorrect fuel delivery timing. Regular inspection and maintenance can help identify and address these problems early 2.

Maintenance Tips for Fuel Injection Pumps

Regular maintenance is recommended to ensure optimal performance and longevity. This includes inspecting for wear or damage, cleaning the fuel system, and replacing worn parts as necessary. Adhering to manufacturer-recommended maintenance schedules and using high-quality fuel can also contribute to the pump’s longevity and efficiency 3.

Cummins: A Brief Overview

Cummins Inc. is a global leader in diesel engine technology, known for its innovation and quality. The company offers a range of engines and components for heavy-duty applications, demonstrating its commitment to advancing diesel engine performance and efficiency 4.

Cummins Fuel Injection Pump 3926887 Compatibility

The Cummins Fuel Injection Pump part number 3926887 is designed for optimal performance and efficiency in various engine models. It is engineered for precise fuel metering, essential for maintaining engine power output and fuel economy.

6C8.3 Engines

The Cummins 6C8.3 engine, used in agricultural and industrial machinery, is compatible with the 3926887 fuel injection pump. This pump ensures smooth operation and longevity of the engine by providing the necessary fuel delivery system 1.

Grouping of Compatible Engines

The 3926887 fuel injection pump is also compatible with other similar Cummins engine models, which often share common design principles and requirements, making it a versatile choice for multiple applications.

Key Considerations

When considering compatibility, ensure the pump’s specifications align with the engine’s fuel delivery needs, including fuel pressure, injection timing, and flow rate.

Application Scenarios

The 3926887 fuel injection pump is beneficial in heavy-duty machinery, where consistent and reliable fuel delivery is paramount. Its precision in fuel metering helps maintain engine performance and efficiency, reducing wear and tear and extending the engine’s operational life 2.

Role of Part 3926887 Fuel Injection Pump in Engine Systems

In modern engine systems, the integration of the Fuel Injection Pump (FIP), specifically part 3926887, is fundamental to efficient engine operation. The FIP works with the base fuel pump to ensure optimal fuel delivery and combustion.

The Base Fuel Pump pressurizes fuel from the tank to a level suitable for the FIP. The FIP then increases the pressure significantly, metering and injecting fuel into the combustion chamber at precise moments dictated by the engine’s control unit. The timing and quantity of fuel injection are critical for achieving efficient combustion, maximizing power output, and minimizing emissions 3.

The interplay between the base fuel pump and the FIP ensures a continuous and regulated flow of fuel. The FIP’s ability to precisely control fuel injection allows for fine-tuning of engine performance, fuel efficiency, and emission levels. This component is integral to the engine’s ability to operate under a wide range of conditions 4.

Conclusion

The Cummins 3926887 Fuel Injection Pump is a vital component for heavy-duty trucks, ensuring precise fuel delivery to optimize engine performance and efficiency. Its advanced features, compatibility with various engine models, and the importance of regular maintenance contribute to its reliability and effectiveness in demanding applications.

-

Thomas Schuetz, Aerodynamics of Road Vehicles: Fifth Edition, SAE International, 2016.

↩ ↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition, Robert Bosch GmbH, 2014.

↩ ↩ ↩ -

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ ↩ ↩ -

Allan Bonnick, A Practical Approach to Motor Vehicle Engineering and Maintenance, Elsevier, 2004.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.