This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

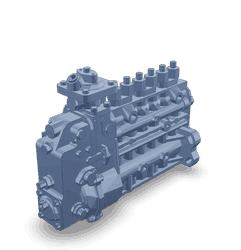

The Cummins 3928595 Fuel Injection Pump is a vital component in the operation of commercial trucks. It is designed to deliver precise amounts of fuel to the engine, ensuring optimal performance and efficiency. This part is integral to the fuel delivery system, playing a significant role in the overall functionality of diesel engines used in heavy-duty applications.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, this pump operates by creating high-pressure fuel that is injected into the cylinders at precise moments in the engine cycle. The pump’s role is to ensure that the fuel is delivered in the correct quantity and at the right time, which is crucial for efficient combustion and engine performance 1.

Role of the Cummins 3928595 Fuel Injection Pump in Truck Operation

The Cummins 3928595 Fuel Injection Pump is specifically engineered to enhance the fuel delivery system in trucks. It works by precisely metering and injecting fuel into the engine’s cylinders, which contributes to improved engine performance and efficiency. This part ensures that the fuel is delivered under high pressure, which is necessary for proper atomization and combustion in diesel engines. Its accurate fuel delivery helps maintain consistent engine power and reduces emissions 2.

Key Features of the Cummins 3928595 Fuel Injection Pump

The Cummins 3928595 Fuel Injection Pump is characterized by its robust design and advanced technical specifications. It features a high-pressure delivery system, precise fuel metering, and durable construction. The pump includes components such as the plunger, cam, and injection nozzles, all of which work together to ensure reliable fuel delivery. Its design is tailored to withstand the demanding conditions of commercial truck operations.

Benefits of Using the Cummins 3928595 Fuel Injection Pump

Utilizing the Cummins 3928595 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered in the optimal quantity and at the right time. This results in enhanced engine performance, with smoother operation and increased power output. Additionally, the pump’s reliable design ensures consistent operation, reducing the likelihood of engine issues and contributing to overall vehicle reliability.

Troubleshooting Common Issues with Fuel Injection Pumps

Common issues with fuel injection pumps can include leaks, inconsistent fuel delivery, and pump failure. Symptoms to watch for include engine misfires, reduced power, and difficulty starting the engine. Addressing these issues may involve inspecting the pump for leaks, cleaning or replacing fuel filters, and ensuring that the pump is properly lubricated. Regular maintenance and timely repairs can help prevent more serious problems.

Maintenance Tips for Fuel Injection Pumps

To ensure the longevity and optimal performance of the Cummins 3928595 Fuel Injection Pump, routine maintenance is essential. This includes regular inspection for leaks, cleaning fuel filters, and checking the pump’s lubrication. Additionally, following the manufacturer’s recommended service intervals for pump replacement or overhaul can help maintain efficient operation. Proper maintenance practices contribute to the pump’s reliability and the overall performance of the truck’s engine.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is known for its commitment to innovation and quality. The company has a history of developing reliable and efficient engine components, including fuel injection pumps, that are designed to meet the demanding needs of commercial and industrial applications.

Cummins Fuel Injection Pump 3928595 Compatibility

The Cummins Fuel Injection Pump part number 3928595 is designed to integrate seamlessly with various engine models, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of modern diesel engines, providing precise fuel delivery and enhancing overall engine efficiency.

Engine Compatibility

-

6B5.9 Series: The 3928595 fuel injection pump is specifically tailored for the 6B5.9 engines. Its design ensures that it fits perfectly within the engine’s architecture, facilitating smooth operation and maintaining the engine’s performance standards.

-

Grouped Applications: This fuel injection pump is also compatible with other models within the same engine family, ensuring a consistent fit across various applications. The design and engineering of the 3928595 pump make it a versatile component suitable for multiple engine configurations.

Installation and Integration

The installation of the Cummins Fuel Injection Pump 3928595 is straightforward, thanks to its precise engineering. It is designed to interface with the engine’s fuel system components without requiring extensive modifications. This ease of installation helps minimize downtime and ensures that the engine can return to operation quickly.

Performance and Reliability

The 3928595 fuel injection pump is built to deliver reliable performance, ensuring that the engine operates at peak efficiency. Its design incorporates advanced features that enhance fuel atomization and distribution, leading to improved combustion and reduced emissions. This makes it an ideal choice for both new installations and replacements in existing systems.

Role of Part 3928595 Fuel Injection Pump in Engine Systems

The Part 3928595 Fuel Injection Pump is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery to the engine cylinders.

Interaction with the Base Fuel Pump

The Base Fuel Pump is responsible for drawing fuel from the tank and delivering it to the Fuel Injection Pump at a consistent pressure. The Fuel Injection Pump then takes this pressurized fuel and further increases its pressure to the levels required for injection into the engine cylinders. This high-pressure fuel is then metered and injected into the combustion chamber at the precise moment needed for optimal engine performance and efficiency.

Coordination with Fuel Injectors

Once the fuel is pressurized by the Fuel Injection Pump, it is distributed to the Fuel Injectors. These injectors are responsible for spraying the fuel into the engine cylinders in a fine mist. The timing and duration of this injection are controlled by the engine’s Electronic Control Unit (ECU), which receives input from various sensors to determine the optimal injection parameters.

Integration with the Engine Control Unit (ECU)

The ECU plays a significant role in the operation of the Fuel Injection Pump. It monitors various engine parameters such as engine speed, load, temperature, and air intake. Based on this data, the ECU sends signals to the Fuel Injection Pump to adjust the fuel pressure and flow rate accordingly. This ensures that the engine receives the correct amount of fuel under all operating conditions, leading to improved performance, fuel efficiency, and reduced emissions.

Synergy with Sensors and Actuators

Several sensors, such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensor, and Manifold Absolute Pressure (MAP) sensor, provide real-time data to the ECU. This data is crucial for the ECU to make accurate adjustments to the fuel delivery system. Actuators, such as the throttle position sensor and various solenoids, work in tandem with the Fuel Injection Pump to fine-tune the fuel delivery process.

Contribution to Overall Engine Performance

The Fuel Injection Pump, by ensuring precise and timely fuel delivery, contributes significantly to the overall performance of the engine. It helps in achieving a better air-fuel mixture, which leads to more complete combustion, higher power output, and lower fuel consumption. Additionally, it plays a role in reducing harmful emissions by ensuring that the fuel is burned more efficiently 3.

Conclusion

The Cummins 3928595 Fuel Injection Pump is a critical component in the fuel delivery system of commercial trucks. Its precise fuel metering and high-pressure delivery ensure optimal engine performance and efficiency. Regular maintenance and timely repairs are essential to maintain the pump’s reliability and the overall performance of the truck’s engine. Cummins’ commitment to innovation and quality ensures that this part meets the demanding needs of modern diesel engines.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

P A Lakshminarayanan and Yogesh V Aghav, Modelling Diesel Combustion (Springer Science, 2010).

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain (Springer, 2015).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.