This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

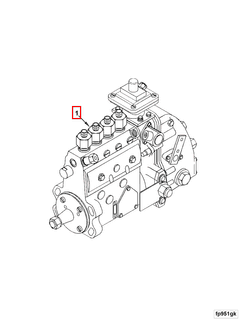

The Cummins 3930156 Fuel Injection Pump is designed for commercial trucks to enhance diesel engine performance and efficiency. This pump ensures controlled and precise fuel delivery, vital for optimal engine function.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes fuel and delivers it to the engine’s combustion chambers at the correct timing and pressure. In diesel engines, this pump ensures fuel is injected into the cylinders at the precise moment needed for combustion, directly influencing fuel atomization and combustion efficiency 1.

Purpose of the Cummins 3930156 Fuel Injection Pump

This Cummins part is designed to deliver fuel at precise timing and pressure, ensuring correct fuel atomization upon injection for efficient combustion. It maintains consistent fuel delivery, fundamental for engine performance, power output, and fuel efficiency.

Key Features

This part features a robust design with high-quality materials to withstand commercial truck operations. It includes precision-machined components for accurate fuel delivery and may incorporate electronic controls for fine-tuning fuel delivery parameters, enhancing performance and reliability.

Benefits

The advantages of this part include improved fuel efficiency, enhanced engine performance, and increased reliability. Precise fuel delivery contributes to more efficient combustion, leading to better fuel economy. Its design and construction support durable operation, reducing failures and maintenance needs.

Installation and Integration

Installing this part in a truck involves following manufacturer guidelines for proper integration. This may include modifications or adjustments to the fuel system. Attention to alignment, sealing, and connection integrity is crucial for optimal performance and safety.

Troubleshooting Common Issues

Common issues with this part can include fuel delivery consistency, leaks, or pump failure. Potential causes range from wear and tear to incorrect installation. Solutions often involve inspecting and replacing worn components, ensuring proper installation, or adjusting pump settings to resolve delivery issues.

Maintenance Practices

Regular maintenance is recommended to ensure the longevity and optimal performance of this part. This includes periodic checks for leaks, ensuring secure connections, and monitoring pump performance. Servicing intervals should be observed to replace filters, inspect for wear, and perform necessary adjustments or repairs.

Performance Enhancements

Upgrades or modifications to this part can include electronic tuning for precise fuel delivery or adding performance parts to increase fuel flow. These enhancements can lead to improved truck performance, including increased power output and efficiency, provided they are compatible with the engine and fuel system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. Known for its commitment to quality, innovation, and customer satisfaction, Cummins is a preferred choice for commercial vehicle operators and manufacturers.

Cummins Fuel Injection Pump 3930156 Compatibility

This part is designed to fit seamlessly with various Cummins engines, enhancing their efficiency and reliability.

Engine Compatibility

- 4B3.9 Series: This part is specifically engineered to integrate with the 4B3.9 engine series, ensuring precise fuel delivery and optimal engine performance.

- Other Cummins Engines: It is also compatible with other Cummins engines that share similar design and operational requirements, ensuring consistent performance across different engine models.

Role of Part 3930156 Fuel Injection Pump in Engine Systems

This part is integral to the efficient operation of engine systems by ensuring precise fuel delivery to the combustion chambers.

Integration with Base Fuel Pump

The base fuel pump draws fuel from the tank and delivers it to the fuel injection pump. This part receives this pressurized fuel and further increases its pressure to the levels required for injection into the engine cylinders. This high-pressure fuel is then metered and timed for optimal combustion efficiency.

Interaction with Fuel Injectors

Once pressurized by this part, fuel is distributed to the fuel injectors, which spray atomized fuel into the combustion chambers at precise moments dictated by the engine’s control unit. The accuracy of this timing and the consistency of fuel pressure are essential for maintaining engine performance and reducing emissions.

Coordination with Engine Control Unit (ECU)

The Engine Control Unit (ECU) regulates the operation of this part. Sensors provide real-time data on engine load, speed, and other parameters to the ECU, which then adjusts the fuel injection timing and pressure. This dynamic interaction ensures that the engine operates efficiently under varying conditions.

Contribution to Fuel Rail System

In systems equipped with a fuel rail, this part supplies consistent high-pressure fuel to the rail. The fuel rail then distributes this fuel to each injector, ensuring uniform fuel delivery across all cylinders. This setup enhances engine balance and performance.

Role in Common Rail Systems

In common rail fuel systems, this part maintains a constant high-pressure reservoir of fuel. This allows for more flexible and precise control over fuel injection events, contributing to improved fuel economy and reduced emissions.

Synergy with Turbochargers

In turbocharged engines, this part must deliver fuel at pressures that match the increased air density provided by the turbocharger. This ensures that the fuel-air mixture remains optimal, maximizing power output and efficiency.

Interaction with Exhaust Gas Recirculation (EGR) System

The EGR system recirculates a portion of the exhaust gases back into the intake stream to reduce NOx emissions. This part must adapt to these changing conditions by adjusting fuel delivery to maintain efficient combustion despite the altered air-fuel ratio.

By understanding how this part interacts with these components, engineers and mechanics can better diagnose issues, optimize performance, and ensure the longevity of engine systems.

Conclusion

The Cummins 3930156 Fuel Injection Pump plays a crucial role in the efficient operation of diesel engines in commercial trucks. Its precise fuel delivery, robust design, and compatibility with various Cummins engines make it a vital component for maintaining engine performance, power output, and fuel efficiency. Regular maintenance and understanding its interaction with other engine components are essential for optimal performance and longevity.

-

Caines, Arthur J, Roger F Haycock, and John E Hillier. Automotive Lubricants Reference Book. SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.