This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3930160 Fuel Injection Pump is a component designed for use in heavy-duty trucks, playing a significant role in the operation of diesel engines. Within the context of diesel engine technology, this pump is integral to ensuring efficient fuel delivery, which is vital for engine performance, fuel economy, and emissions control 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers at precise moments and in specific quantities. It operates by pressurizing fuel and injecting it into the engine cylinders, where it mixes with air and ignites. The importance of fuel injection pumps in diesel engines lies in their ability to control fuel delivery, which directly affects engine performance, efficiency, and emissions 2. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems use sensors and electronic control units (ECUs) to manage fuel injection more precisely.

Purpose of the Cummins 3930160 Fuel Injection Pump

The Cummins 3930160 Fuel Injection Pump is specifically designed to enhance the operation of heavy-duty trucks. It plays a role in the engine’s fuel system by ensuring that fuel is delivered at the correct pressure and timing. This precise fuel delivery contributes to engine performance by optimizing combustion, which in turn improves fuel efficiency and reduces emissions. The pump’s design allows for consistent fuel distribution across all cylinders, which is crucial for maintaining engine balance and power output.

Key Features

The Cummins 3930160 Fuel Injection Pump is characterized by several key features that enhance its performance and reliability. Its design incorporates advanced technology to ensure precise fuel delivery. Constructed from durable materials, the pump is built to withstand the harsh conditions of heavy-duty truck operation. Unique technological advancements within the pump, such as improved sealing mechanisms and precision-machined components, contribute to its efficiency and longevity. These features work together to provide consistent fuel delivery, which is essential for optimal engine performance.

Benefits

The advantages offered by the Cummins 3930160 Fuel Injection Pump include improved fuel economy, enhanced engine power, reduced emissions, and increased durability. These benefits translate to real-world advantages for truck operators and fleet managers, such as lower operating costs, increased productivity, and compliance with emissions regulations. The pump’s efficient fuel delivery system ensures that the engine operates at peak efficiency, which can lead to significant savings in fuel costs over time. Additionally, the reduction in emissions contributes to a cleaner operating environment, which is beneficial for both the operator and the community.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3930160 Fuel Injection Pump include fuel delivery inconsistencies, leaks, and mechanical wear. Troubleshooting steps may involve checking fuel lines for blockages, inspecting seals for wear, and ensuring the pump is properly lubricated. Routine maintenance procedures to ensure optimal performance and longevity of the pump include regular inspection of components, cleaning or replacing filters, and monitoring fuel system pressure. Identifying signs of wear or malfunction, such as unusual engine noises or a decrease in performance, can indicate the need for professional service. Regular maintenance and prompt attention to any issues can help extend the life of the pump and ensure consistent engine performance.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the diesel engine industry. Founded with a commitment to innovation and quality, Cummins has established itself as a leader in diesel engine technology, with a particular focus on fuel injection systems. The company’s expertise in designing and producing reliable, high-performance diesel engines and components is evident in products like the Cummins 3930160 Fuel Injection Pump. Cummins’ dedication to advancing diesel technology ensures that their products meet the demanding requirements of heavy-duty applications, providing operators with the performance, efficiency, and durability needed for their operations.

Cummins Fuel Injection Pump 3930160 Compatibility

The Cummins Fuel Injection Pump part number 3930160 is a critical component in the operation of several diesel engines, ensuring precise fuel delivery and optimal engine performance. This part is specifically designed to fit seamlessly with the following engines:

- 6B5.9

The 3930160 fuel injection pump is engineered to provide reliable and efficient fuel delivery, enhancing the overall performance and longevity of the engine. Its compatibility with the 6B5.9 engine ensures that the pump can handle the specific demands of this engine model, maintaining consistent fuel pressure and timing for smooth operation.

When installed in the 6B5.9 engine, the 3930160 fuel injection pump ensures that the engine operates at peak efficiency, delivering the necessary power and fuel economy expected from Cummins engines. This compatibility is crucial for maintaining the engine’s performance and reliability, making the 3930160 a vital component for engine maintenance and repair.

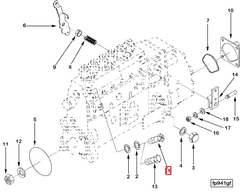

Role of Part 3930160 Fuel Injection Pump in Engine Systems

The part 3930160 Fuel Injection Pump is integral to the efficient operation of engine systems by ensuring precise fuel delivery. This component works in conjunction with several other parts to optimize engine performance.

Integration with the Fuel System

-

Fuel Tank: The fuel injection pump draws diesel from the fuel tank. It is essential that the fuel is clean and free of contaminants to ensure the pump operates efficiently.

-

Fuel Filter: Before the fuel reaches the injection pump, it passes through the fuel filter. This step is vital for removing impurities that could damage the sensitive components within the pump.

-

Fuel Lines: The pump is connected to the fuel lines, which transport the fuel from the tank to the injection pump and subsequently to the injectors. The integrity of these lines is important for maintaining consistent fuel pressure.

Operation within the Engine

-

Injectors: The fuel injection pump pressurizes the fuel and delivers it to the injectors. The injectors then spray atomized fuel into the combustion chamber at precise moments, which is essential for efficient combustion.

-

Combustion Chamber: The atomized fuel mixes with air in the combustion chamber. The timing and pressure of the fuel delivery, controlled by the injection pump, are key factors in achieving optimal combustion efficiency and power output.

-

Engine Control Unit (ECU): In modern engines, the ECU monitors and adjusts the operation of the fuel injection pump. Sensors provide data on engine load, speed, and other parameters, allowing the ECU to fine-tune fuel delivery for maximum performance and efficiency.

Supporting Components

-

Timing Mechanism: The fuel injection pump must be synchronized with the engine’s timing mechanism to ensure that fuel is delivered at the correct moment in the engine cycle.

-

Governor: The governor regulates the amount of fuel delivered by the pump, adjusting it based on engine speed and load conditions. This helps maintain consistent engine performance across a range of operating conditions.

-

Return Lines: Excess fuel not injected into the combustion chamber is returned to the fuel tank via return lines. This system helps maintain consistent fuel pressure and temperature within the injection pump.

By understanding how the part 3930160 Fuel Injection Pump interacts with these components, engineers and mechanics can better diagnose issues, perform maintenance, and optimize engine performance.

Conclusion

The Cummins 3930160 Fuel Injection Pump is a critical component in the operation of heavy-duty diesel engines, ensuring efficient fuel delivery and optimal engine performance. Its advanced features, compatibility with specific engine models, and integration within the engine system contribute to improved fuel economy, enhanced engine power, reduced emissions, and increased durability. Regular maintenance and troubleshooting are essential for ensuring the longevity and consistent performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.