3930163

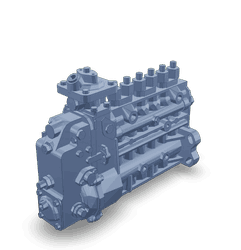

Fuel Injection Pump

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3930163 Fuel Injection Pump is a vital component in the operation of commercial trucks. It plays a significant role in the fuel delivery system, ensuring that the engine receives the precise amount of fuel needed for optimal performance. This pump is designed to deliver fuel to the engine cylinders at the correct pressure and timing, which is essential for efficient combustion and overall engine functionality 1.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps are fundamental to the operation of diesel engines. Their primary function is to deliver fuel to the engine cylinders under high pressure. This process ensures that the fuel is atomized properly, leading to efficient combustion. Precise fuel metering is essential for maintaining engine performance, fuel efficiency, and emissions standards. The pump operates by drawing fuel from the tank, pressurizing it, and delivering it to the injectors at the exact moment required by the engine’s combustion cycle 2.

Purpose of the Cummins 3930163 Fuel Injection Pump

The Cummins 3930163 Fuel Injection Pump is integral to the operation of a truck’s engine. It is responsible for delivering fuel to the engine cylinders at the correct pressure and timing. This ensures that the fuel is injected into the combustion chamber at the optimal moment, allowing for efficient combustion and maximizing engine performance. The pump’s role in maintaining precise fuel delivery is vital for the overall efficiency and reliability of the engine 3.

Key Features

The Cummins 3930163 Fuel Injection Pump boasts several key features that enhance its performance and durability. Its design incorporates high-quality construction materials, ensuring longevity and reliability under demanding conditions. The pump may also feature unique technological advancements, such as improved seals and precision-machined components, which contribute to its efficient operation and reduced maintenance requirements 4.

Benefits

The Cummins 3930163 Fuel Injection Pump offers several benefits that contribute to the overall performance of a truck’s engine. These include improved fuel efficiency, as the precise fuel metering ensures that the engine operates at its most efficient point. Enhanced engine performance is another advantage, as the consistent and accurate fuel delivery leads to smoother operation and increased power output. Additionally, the pump helps in reducing emissions by ensuring that the fuel is combusted more cleanly and efficiently 5.

Installation and Integration

Proper installation and integration of the Cummins 3930163 Fuel Injection Pump within a truck’s engine system are crucial for its optimal performance. This process involves ensuring that the pump is correctly aligned and securely mounted. Any necessary adjustments or configurations should be made according to the manufacturer’s guidelines to ensure that the pump operates within the specified parameters. Attention to detail during installation can prevent future issues and ensure the longevity of the pump 6.

Troubleshooting Common Issues

Common problems associated with fuel injection pumps include leaks, misfires, and irregular engine performance. Troubleshooting these issues involves a systematic approach to identify the root cause. For leaks, inspecting the pump and its connections for signs of wear or damage is necessary. Misfires may indicate issues with fuel delivery timing or pressure, requiring adjustments or component replacements. Irregular engine performance could be due to a variety of factors, including clogged fuel filters or malfunctioning injectors, and should be diagnosed through a thorough inspection 7.

Maintenance Practices

Regular maintenance of the Cummins 3930163 Fuel Injection Pump is essential for its continued reliable operation. This includes periodic inspections to check for signs of wear or damage, cleaning procedures to remove any contaminants that may affect performance, and replacement of wear-prone components at recommended intervals. Adhering to a maintenance schedule helps in preventing unexpected failures and ensures the pump operates efficiently throughout its service life 8.

Performance Optimization

Optimizing the performance of the Cummins 3930163 Fuel Injection Pump can be achieved through various techniques. Fine-tuning fuel delivery parameters, such as injection timing and pressure, can lead to improved engine efficiency and power output. Additionally, upgrading components, such as injectors or filters, can enhance the overall performance of the fuel delivery system. Regular monitoring and adjustments based on engine performance data can further optimize the pump’s operation 9.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a rich history in the diesel engine industry. The company is known for its commitment to innovation and quality, providing reliable and high-performance diesel engine technology. Cummins’ reputation is built on its dedication to advancing engine technology, ensuring that its products meet the demanding requirements of commercial and industrial applications. The company’s focus on research and development continues to drive its success in the competitive diesel engine market 10.

Cummins Fuel Injection Pump 3930163 Compatibility

The Cummins Fuel Injection Pump part number 3930163 is a critical component in the operation of various diesel engines, ensuring precise fuel delivery and optimal engine performance. This part is designed to fit seamlessly with several engine models, enhancing their efficiency and reliability.

Engine Compatibility

-

6B5.9 Series Engines

- The 3930163 fuel injection pump is specifically engineered to integrate with the 6B5.9 series engines. These engines are known for their robust construction and are widely used in various industrial and commercial applications. The compatibility ensures that the pump meets the stringent demands of these engines, providing consistent fuel delivery and maintaining engine performance.

-

Other Cummins Engines

- While the primary focus is on the 6B5.9 series, the 3930163 fuel injection pump is also compatible with other Cummins engines. This versatility makes it a valuable component for technicians and fleet managers who operate a diverse range of Cummins-powered vehicles and machinery. The pump’s design allows it to work efficiently across different engine configurations, ensuring that the fuel injection system operates smoothly and reliably.

Importance of Proper Fitment

Ensuring that the fuel injection pump fits correctly with the engine is crucial for maintaining engine performance and longevity. The 3930163 part is manufactured to precise specifications, ensuring a perfect match with the engine’s fuel injection system. This compatibility is vital for preventing issues such as fuel leaks, poor engine performance, and potential engine damage.

Installation Considerations

When installing the 3930163 fuel injection pump, it is essential to follow the manufacturer’s guidelines and recommendations. Proper installation ensures that the pump operates efficiently and extends the lifespan of both the pump and the engine. Technicians should also verify that all related components, such as fuel lines and connectors, are in good condition and compatible with the pump.

Performance Benefits

The use of the 3930163 fuel injection pump in compatible engines offers several performance benefits. These include improved fuel efficiency, enhanced engine power, and reduced emissions. The pump’s precise fuel delivery mechanism ensures that the engine receives the correct amount of fuel at the right time, optimizing combustion and overall engine performance.

Role of Part 3930163 Fuel Injection Pump in Engine Systems

The part 3930163 Fuel Injection Pump, specifically designed by Bosch, is an integral component in the fuel delivery system of diesel engines. It works in conjunction with several other components to ensure efficient and precise fuel delivery.

Integration with Bosch Injection System

When integrated into a Bosch injection system, the 3930163 Fuel Injection Pump operates by receiving fuel from the tank via the fuel filter. It then pressurizes the fuel to the required levels before distributing it to the injectors. The pump’s role is to maintain consistent fuel pressure, which is essential for the injectors to atomize the fuel properly upon injection into the combustion chamber.

Interaction with Injectors

The pressurized fuel from the 3930163 Pump is delivered to the injectors, which are responsible for spraying atomized fuel into the engine’s cylinders. The precision of this spray is influenced by the pump’s ability to deliver consistent pressure, ensuring optimal combustion efficiency and performance.

Coordination with Engine Control Unit (ECU)

In modern diesel engines, the 3930163 Fuel Injection Pump often works in tandem with the Engine Control Unit (ECU). The ECU monitors various engine parameters and adjusts the pump’s operation to optimize fuel delivery based on real-time data, such as engine load, speed, and temperature.

Role in Common Rail Systems

In common rail fuel systems, the 3930163 Pump contributes to maintaining a high-pressure fuel reservoir. This reservoir allows for more precise control over fuel injection timing and quantity, enhancing engine performance and reducing emissions.

Contribution to Fuel Efficiency and Emissions Control

By ensuring that fuel is delivered at the correct pressure and timing, the 3930163 Pump plays a significant role in improving fuel efficiency and reducing emissions. Efficient fuel delivery leads to more complete combustion, which not only saves fuel but also minimizes the release of harmful pollutants.

Support from Ancillary Components

The effective operation of the 3930163 Pump is supported by ancillary components such as the fuel filter, which ensures that contaminants are removed from the fuel before it reaches the pump, and the fuel return system, which manages excess fuel and maintains system pressure.

Conclusion

The Cummins 3930163 Fuel Injection Pump is a key component in the fuel delivery system, working in harmony with injectors, the ECU, and other ancillary components to ensure optimal engine performance, fuel efficiency, and emissions control. Proper installation, maintenance, and optimization of this part are essential for maximizing its benefits and ensuring the longevity and reliability of the engine system.

-

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.