This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3963952 Fuel Injection Pump is a component designed for use in commercial trucks, manufactured by Cummins Inc. Cummins is renowned for its high-quality diesel engines and components, and this fuel injection pump is no exception. It plays a role in the efficient operation of trucks by ensuring precise fuel delivery to the engine 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers at the correct pressure and timing. In diesel engines, the fuel injection pump operates by pressurizing fuel and injecting it into the combustion chamber at precise moments in the engine cycle. This process relies on several components, including the pump, injectors, and control mechanisms, to ensure optimal fuel atomization and combustion 2.

Purpose of the Cummins 3963952 Fuel Injection Pump

The Cummins 3963952 Fuel Injection Pump is integral to the operation of a truck’s diesel engine. It ensures that fuel is delivered at the correct pressure and timing, which contributes to engine performance, fuel efficiency, and emissions control. By precisely metering the fuel, the pump helps achieve efficient combustion, which is vital for the engine’s power output and overall efficiency 3.

Key Features

The Cummins 3963952 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials, which enhance its durability and performance. It incorporates advanced technological features such as precise fuel metering and efficient pressure regulation. These features contribute to the pump’s reliability and effectiveness in demanding commercial truck applications 4.

Benefits

Using the Cummins 3963952 Fuel Injection Pump offers several advantages. It contributes to improved fuel economy by ensuring efficient fuel delivery. Enhanced engine performance is achieved through precise fuel injection, which optimizes combustion. Additionally, the pump helps reduce emissions by promoting cleaner burning fuel. Its durable construction ensures long-term reliability and reduced maintenance needs 5.

Installation and Integration

Proper installation of the Cummins 3963952 Fuel Injection Pump is crucial for its effective operation. It should be integrated into the truck’s engine system following manufacturer guidelines to ensure compatibility and optimal performance. Considerations such as correct alignment, secure mounting, and proper connection to the fuel system are important for successful installation 6.

Troubleshooting and Maintenance

Common issues with the Cummins 3963952 Fuel Injection Pump may include fuel delivery problems, leaks, or performance inconsistencies. Troubleshooting steps involve checking for proper installation, inspecting connections, and ensuring the pump is receiving the correct electrical signals. Regular maintenance, including cleaning and inspecting for wear, is important to ensure the longevity and optimal performance of the pump 7.

Performance Optimization

To optimize the performance of the Cummins 3963952 Fuel Injection Pump, strategies such as tuning and upgrades can be employed. These may include adjusting fuel delivery parameters, using high-quality fuel filters, and ensuring the pump is well-maintained. Such measures can enhance the efficiency and effectiveness of the pump, contributing to better overall engine performance 8.

Cummins Overview

Cummins Inc. has a long-standing reputation in the industry for manufacturing high-quality diesel engines and components. The company is committed to innovation and quality, which is reflected in its products, including the Cummins 3963952 Fuel Injection Pump. Cummins’ dedication to advancing diesel technology ensures that its components meet the demanding requirements of commercial truck applications 9.

Compatibility

The Cummins Fuel Injection Pump part number 3963952 is designed to be compatible with a range of engine models, ensuring efficient and reliable fuel delivery across various applications. This part is engineered to meet the stringent demands of heavy-duty operations, providing consistent performance and durability.

Compatible Engines

- 6B5.9: This engine model benefits from the precise fuel metering capabilities of the 3963952 pump, enhancing overall engine efficiency and power output.

Grouping of Compatible Engines

The 3963952 fuel injection pump is particularly suited for engines within the Cummins B-Series family, which includes the 6B5.9. These engines are known for their robust construction and are widely used in various industrial and commercial applications. The compatibility of the 3963952 pump with these engines ensures that users can maintain optimal engine performance and longevity.

By integrating the 3963952 fuel injection pump into engines like the 6B5.9, users can expect improved fuel economy, reduced emissions, and enhanced operational reliability. This compatibility underscores Cummins’ commitment to providing high-quality components that support the performance and durability of their engines.

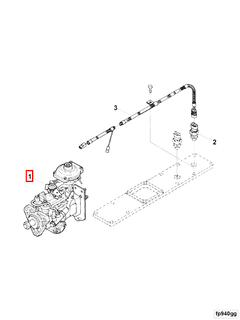

Role of Part 3963952 Fuel Injection Pump in Engine Systems

The Part 3963952 Fuel Injection Pump is a pivotal component in the orchestration of fuel delivery within engine systems. It works in harmony with various components to ensure optimal engine performance.

Integration with the Fuel System

The Fuel Injection Pump, identified as Part 3963952, is responsible for pressurizing the fuel and delivering it to the injectors at precise moments. This pressurized fuel is then atomized into the combustion chamber, where it mixes with air and ignites, driving the engine’s pistons.

Interaction with the Pump

The pump, often a high-pressure pump driven by the engine’s camshaft or a separate electric motor, supplies the Fuel Injection Pump with a steady flow of fuel. The efficiency of this pump directly influences the performance of the Fuel Injection Pump, as consistent fuel pressure is essential for accurate fuel metering.

Fuel Delivery and Engine Performance

The Fuel Injection Pump’s role extends to regulating the amount of fuel injected, which is critical for maintaining the engine’s power output and fuel efficiency. It must work in sync with the engine’s control unit, which monitors various parameters such as engine load, speed, and temperature to adjust the fuel delivery accordingly.

Coordination with Injectors

Once the fuel is pressurized by the Fuel Injection Pump, it is delivered to the injectors. These injectors, under the command of the engine control unit, open and close at specific intervals to release the fuel into the combustion chamber. The timing and duration of this release are finely tuned to ensure complete combustion and minimize emissions.

Feedback Loop with Sensors

Sensors throughout the engine system provide real-time data to the engine control unit. This data includes information on air-fuel ratio, exhaust gas composition, and engine temperature. The Fuel Injection Pump adjusts its operation based on this feedback to maintain optimal engine performance and emissions levels.

Conclusion

In summary, the Part 3963952 Fuel Injection Pump is a sophisticated component that plays a significant role in the fuel delivery process. Its precise operation, in conjunction with the pump and injectors, is essential for the efficient and effective running of engine systems.

-

Williams, Daniel. Generalized Vehicle Dynamics. SAE International, 2022.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4388741, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4388741, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4388741, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4388741, 2023.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 4388741, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.