This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

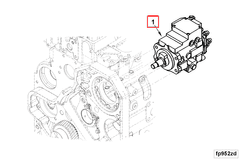

The Cummins 3964556 Fuel Injection Pump is a vital component in the operation of commercial trucks, particularly those equipped with Cummins diesel engines. This part is designed to deliver precise amounts of fuel to the engine’s combustion chambers, ensuring efficient and reliable performance. Its role in the fuel delivery system is significant, contributing to the overall efficiency and power output of the vehicle.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, the pump plays a role in injecting fuel at high pressure into the cylinders, where it mixes with air and ignites. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and electronic controls to optimize fuel injection based on engine conditions and performance requirements 2.

Purpose and Function of the Cummins 3964556 Fuel Injection Pump

The Cummins 3964556 Fuel Injection Pump is responsible for delivering fuel to the engine in a controlled and precise manner. It ensures that the correct amount of fuel is injected at the right time, which is important for efficient combustion and engine performance. The pump operates by drawing fuel from the tank, pressurizing it, and then distributing it to the injectors, which spray the fuel into the combustion chambers.

Key Features

The Cummins 3964556 Fuel Injection Pump is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality materials to withstand the rigors of commercial truck operation. The pump features precise engineering to ensure accurate fuel delivery, and it includes advanced technological aspects such as electronic controls that allow for fine-tuning of fuel injection parameters. Additionally, the pump is built to be durable, with robust construction that can handle the demands of heavy-duty applications.

Benefits of Using the Cummins 3964556 Fuel Injection Pump

Utilizing the Cummins 3964556 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered in the optimal quantity and at the precise moment. This results in more complete combustion and reduced fuel consumption. The pump also enhances engine performance by providing consistent and reliable fuel delivery, which is important for maintaining power output and responsiveness. Furthermore, the pump’s design and construction contribute to its reliability, reducing the likelihood of failures and downtime.

Common Issues and Troubleshooting

Fuel injection pumps, including the Cummins 3964556, can encounter issues that affect their performance. Common problems include fuel leaks, inconsistent fuel delivery, and pump failure. Symptoms of these issues may include engine misfires, reduced power, and difficulty starting the engine. Troubleshooting typically involves inspecting the pump for leaks, checking the fuel lines for blockages, and ensuring that the pump is receiving proper electrical signals if it is an electronic model. Diagnostic procedures may also include testing the pump’s pressure output and examining the injectors for proper operation 1.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3964556 Fuel Injection Pump, regular maintenance is recommended. This includes inspecting the pump and fuel lines for signs of wear or damage, cleaning the pump and injectors to remove any buildup, and replacing wear parts according to the manufacturer’s schedule. Additionally, keeping the fuel system clean by using high-quality fuel and filters can prevent contaminants from affecting the pump’s operation.

Integration with Engine Management Systems

The Cummins 3964556 Fuel Injection Pump is designed to integrate seamlessly with modern engine management systems. These systems use sensors to monitor various engine parameters, such as temperature, pressure, and load. The data from these sensors is used by the engine control unit (ECU) to adjust the fuel injection timing and quantity in real-time, optimizing engine performance and efficiency. The pump’s electronic controls play a role in this process by responding to signals from the ECU to make precise adjustments to fuel delivery 2.

Historical Development and Technological Advancements

The evolution of fuel injection technology has led to significant advancements in the design and functionality of fuel injection pumps. Early mechanical pumps have given way to more sophisticated electronic systems that offer greater control and efficiency. The development of the Cummins 3964556 Fuel Injection Pump is a result of these technological advancements, incorporating precise engineering and electronic controls to enhance performance and reliability.

Cummins Corporation

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to innovation and quality. The company has a long history of producing reliable and high-performance engines for a variety of applications, including commercial trucks. Cummins’ product range includes a wide array of engines and components, all designed to meet the demanding requirements of the transportation industry. The company’s reputation for quality and durability is upheld by its continuous investment in research and development, ensuring that its products remain at the forefront of technological advancement.

Compatibility

The Cummins Fuel Injection Pump part number 3964556 is designed to be compatible with a range of Cummins diesel engines, ensuring optimal performance and reliability. This part is engineered to meet the specific needs of various engine models, providing precise fuel delivery and efficient combustion.

QSB5.9 Engines

The QSB5.9 engines, known for their robust performance and versatility, are well-suited for the Cummins Fuel Injection Pump 3964556. This part ensures that the QSB5.9 engines maintain their high standards of power and efficiency, making it an important component for these models.

CM550 Engines

The CM550 engines also benefit from the Cummins Fuel Injection Pump 3964556. This part is engineered to provide the precise fuel delivery required by the CM550 engines, ensuring smooth operation and consistent performance. Its compatibility with the CM550 engines highlights its versatility and reliability across different engine types.

Group Compatibility

The Cummins Fuel Injection Pump 3964556 is part of a broader range of components designed to work seamlessly with various Cummins engine models. Its compatibility with the QSB5.9 and CM550 engines demonstrates its adaptability and effectiveness in different applications. This part is an important component for maintaining the performance and longevity of these engines, ensuring they operate at their best under various conditions.

Role of Part 3964556 Fuel Injection Pump in Engine Systems

The part 3964556 Fuel Injection Pump is integral to the operation of diesel engine systems, ensuring precise fuel delivery to the combustion chambers. This component works in harmony with several other engine components to optimize performance and efficiency.

Interaction with the Fuel System

The Fuel Injection Pump is responsible for pressurizing fuel and delivering it to the injectors at the correct moment in the engine cycle. It interfaces directly with the fuel tank, fuel lines, and fuel filters to maintain a consistent flow of clean, pressurized fuel. The pump’s output is regulated by the engine control unit (ECU), which monitors various parameters such as engine speed, load, and temperature to adjust fuel delivery accordingly.

Coordination with Injectors

Once pressurized, the fuel is sent to the injectors, which are precisely timed to spray fuel into the combustion chambers. The Fuel Injection Pump ensures that the injectors receive fuel at the optimal pressure and timing, which is important for efficient combustion and power output. The injectors work in conjunction with the pump to atomize the fuel, creating a fine mist that mixes thoroughly with the air for complete combustion.

Integration with the Engine Control Unit (ECU)

The ECU plays a role in the operation of the Fuel Injection Pump. It receives data from various sensors, including the crankshaft position sensor, camshaft position sensor, and manifold absolute pressure (MAP) sensor. Based on this data, the ECU sends signals to the pump to adjust the fuel delivery rate and pressure, ensuring that the engine operates within its optimal parameters under varying conditions.

Relationship with the Turbocharger

In turbocharged engines, the Fuel Injection Pump must work in sync with the turbocharger to maintain the correct air-fuel ratio. As the turbocharger compresses the intake air, the pump increases fuel delivery to match the higher air density. This coordination is important for maximizing power output while preventing engine knock and other performance issues.

Impact on Emission Control Systems

The precise fuel delivery provided by the Fuel Injection Pump is also important for the proper functioning of emission control systems. By ensuring that the fuel is atomized and combusted efficiently, the pump helps reduce the formation of harmful emissions. This is particularly important for components like the diesel particulate filter (DPF) and selective catalytic reduction (SCR) system, which rely on clean, efficient combustion to operate effectively.

Conclusion

In summary, the part 3964556 Fuel Injection Pump is a key component that interacts with various engine systems to ensure optimal performance, efficiency, and emissions compliance. Its role in pressurized fuel delivery and coordination with other components underscores its importance in modern diesel engine technology.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.