This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

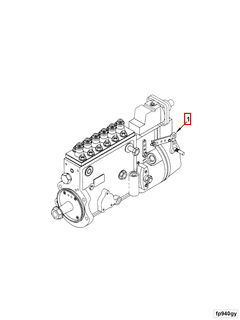

The Cummins 3971475 Fuel Injection Pump is a vital component in the operation of commercial trucks, playing a significant role in the fuel delivery system. This pump ensures that the engine receives the precise amount of fuel needed for optimal performance and efficiency. Understanding its function and importance is key to maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps are designed to deliver fuel to the engine’s combustion chambers at the precise moment and in the exact quantity required. They operate by pressurizing fuel and injecting it into the engine cylinders, where it mixes with air and ignites. This process is crucial for the efficient operation of diesel engines, as it directly influences fuel efficiency, power output, and emissions 2. The principles of fuel injection involve precise timing, pressure regulation, and the coordination of various components such as the pump, injectors, and control systems.

Purpose of the Cummins 3971475 Fuel Injection Pump

This Cummins part is specifically engineered to enhance the operation of trucks by ensuring that fuel is delivered to the engine with precision. This pump contributes to engine performance and efficiency by maintaining consistent fuel pressure and timing, which are critical for combustion. Its role in the fuel delivery system helps to optimize the engine’s power output and fuel economy, making it a key component in the overall performance of the vehicle.

Key Features

The Cummins 3971475 boasts several key features that enhance its performance. These include a robust design that ensures durability under demanding conditions, the use of high-quality materials that resist wear and corrosion, and technological advancements such as precise fuel metering and electronic control options. These features work together to provide reliable and efficient fuel delivery, contributing to the overall performance and longevity of the pump.

Benefits

Using this Cummins part offers several benefits. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the engine in the most efficient manner possible. This results in better fuel economy and reduced operating costs. Additionally, the pump enhances engine performance by providing consistent and precise fuel delivery, which is crucial for maintaining power output and reliability. Its design and construction also contribute to the pump’s durability and longevity, making it a reliable choice for commercial truck applications.

Installation and Integration

When installing the Cummins 3971475, it is important to follow guidelines and considerations to ensure proper integration into the truck’s engine system. Best practices include verifying compatibility with the engine model, ensuring all connections are secure, and following the manufacturer’s instructions for installation 1. Potential challenges may include fitting the pump within the engine compartment and ensuring it operates within the specified parameters for optimal performance.

Maintenance and Troubleshooting

Maintaining the Cummins 3971475 is crucial for ensuring its longevity and optimal performance. Regular maintenance practices include checking for leaks, ensuring all connections are tight, and monitoring the pump’s performance for any signs of wear or malfunction. Common issues may include fuel leaks, inconsistent fuel delivery, or pump failure, which can often be addressed through routine maintenance and timely repairs. Preventive maintenance, such as regular inspections and servicing, can help to identify and resolve issues before they lead to more significant problems.

Performance and Efficiency

The Cummins 3971475 plays a significant role in the overall performance and efficiency of the truck. By ensuring precise fuel delivery, it contributes to improved fuel economy and enhanced engine performance. This results in better power output and more efficient operation, which are critical for the productivity and cost-effectiveness of commercial trucking operations.

Cummins Corporation

Cummins Inc. is a renowned manufacturer with a strong reputation in the industry for innovation and quality. The company has a long history of producing reliable and high-performance automotive components, including fuel injection pumps. Cummins’ commitment to quality and innovation is evident in the design and construction of the 3971475, making it a trusted choice for commercial truck applications.

Cummins Fuel Injection Pump 3971475 Compatibility

The Cummins Fuel Injection Pump part number 3971475 is designed to integrate seamlessly with a variety of engine models, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of heavy-duty applications, providing precise fuel delivery and efficient combustion.

Engine Compatibility

-

6B5.9 Series: The 3971475 fuel injection pump is specifically tailored for the 6B5.9 engine series. This engine is known for its robust construction and high performance in demanding environments. The pump’s design ensures that it can handle the specific fuel requirements and operational conditions of the 6B5.9 engine, enhancing overall efficiency and longevity.

-

Other Cummins Engines: While the primary focus is on the 6B5.9 series, the 3971475 fuel injection pump is also compatible with other Cummins engines that share similar design and operational parameters. This compatibility extends to various models within the Cummins engine lineup, ensuring that users can find a suitable match for their specific needs.

Integration and Performance

The integration of the 3971475 fuel injection pump with Cummins engines is a critical component of the engine’s overall performance. The pump’s precision in delivering fuel directly impacts the engine’s power output, fuel efficiency, and emissions control. By ensuring that the pump is correctly matched with the engine, users can expect improved reliability and performance.

Installation and Maintenance

Proper installation of the 3971475 fuel injection pump is essential to maintain the engine’s performance and longevity. Regular maintenance and timely replacement of the pump, when necessary, are crucial to prevent potential issues and ensure that the engine operates at its best. Cummins provides detailed guidelines and support for the installation and maintenance of this component, ensuring that users can perform these tasks with confidence.

Reliability and Trustworthiness

Cummins is renowned for its commitment to quality and reliability. The 3971475 fuel injection pump is no exception, offering a dependable solution for those seeking to enhance their engine’s performance. The pump’s design and materials are chosen to withstand the rigors of heavy-duty use, providing a long-lasting and reliable component for Cummins engines.

Role of Part 3971475 Fuel Injection Pumps in Engine Systems

The part 3971475 Fuel Injection Pump is integral to the operation of modern engine systems, ensuring efficient and precise fuel delivery. This component works in conjunction with several other parts to optimize engine performance.

Interaction with the Common Rail System

In common rail systems, the fuel injection pump plays a vital role by pressurizing fuel and delivering it to the common rail. The high-pressure fuel is then distributed to individual injectors, which atomize the fuel into the combustion chamber. This process enhances fuel efficiency and reduces emissions 2.

Coordination with Fuel Injectors

The fuel injection pump must be precisely synchronized with the fuel injectors. It ensures that the fuel is delivered at the correct pressure and timing. This coordination is essential for maintaining consistent engine performance and fuel economy.

Integration with the Engine Control Unit (ECU)

The ECU monitors various engine parameters and adjusts the fuel injection pump’s operation accordingly. Sensors provide real-time data on engine load, speed, and temperature, allowing the ECU to fine-tune fuel delivery for optimal performance and emissions control.

Relationship with the Fuel Filter

A clean fuel supply is necessary for the efficient operation of the fuel injection pump. The fuel filter removes contaminants from the fuel before it reaches the pump, ensuring smooth and reliable operation. Regular maintenance of the fuel filter is essential to prevent damage to the injection pump.

Impact on Combustion Efficiency

The fuel injection pump’s ability to deliver fuel at high pressure and precise timing directly influences combustion efficiency. Proper fuel atomization leads to more complete combustion, which enhances power output and reduces fuel consumption.

Influence on Emission Control

Modern engines are equipped with advanced emission control systems that rely on the precise fuel delivery provided by the injection pump. By ensuring accurate fuel metering, the pump helps in meeting stringent emission standards and contributes to a cleaner environment 2.

Synergy with Turbochargers

In turbocharged engines, the fuel injection pump must adapt to the increased air flow provided by the turbocharger. It delivers more fuel to match the higher air volume, ensuring that the air-fuel mixture remains within optimal limits for performance and efficiency.

Contribution to Engine Longevity

Consistent and precise fuel delivery reduces the stress on engine components, contributing to longer engine life. The fuel injection pump’s role in maintaining stable combustion conditions helps prevent premature wear and tear on critical engine parts.

Conclusion

The Cummins 3971475 Fuel Injection Pump is a critical component in the fuel delivery system of commercial trucks. Its precise fuel delivery enhances engine performance, fuel efficiency, and emissions control. Understanding its features, benefits, and integration with other engine components is essential for maintaining and optimizing the performance of commercial trucks. Regular maintenance and proper installation are crucial to ensure the longevity and reliability of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.