This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

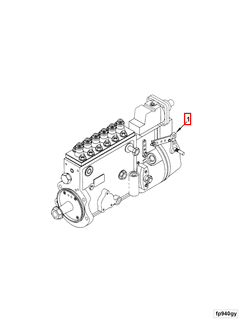

The Cummins 3972351 Fuel Injector Pump is a component designed for use in heavy-duty trucks. Manufactured by Cummins, a well-established name in the automotive industry, this fuel injector pump is integral to the efficient operation of diesel engines in trucks. Its role is to deliver fuel to the engine under precise pressure and timing, ensuring optimal performance and efficiency 1.

Basic Concepts of Fuel Injector Pumps

A fuel injector pump is a device that pressurizes diesel fuel and delivers it to the engine’s injectors. In diesel engines, the fuel injector pump plays a role in the fuel delivery system by ensuring that fuel is injected into the combustion chamber at the correct pressure and timing 2. There are several types of fuel injector pumps, including inline, rotary, and common rail systems, each with specific applications and advantages. This Cummins part is an inline pump, known for its reliability and efficiency in heavy-duty applications.

Role of the 3972351 Fuel Injector Pump in Truck Operation

The 3972351 Fuel Injector Pump contributes significantly to the operation of a truck by ensuring that fuel is delivered to the engine in a controlled and efficient manner. This pump plays a role in engine performance by maintaining consistent fuel pressure, which is crucial for combustion efficiency 3. It also contributes to fuel efficiency by ensuring that the fuel is injected at the optimal time, reducing waste and improving overall engine performance. Furthermore, the pump’s reliable operation is vital for the truck’s functionality, as it ensures that the engine operates smoothly under various conditions.

Key Features of the 3972351 Fuel Injector Pump

The Cummins 3972351 Fuel Injector Pump is characterized by several key features that enhance its performance and durability. Its design incorporates advanced technology to ensure precise fuel delivery. The construction materials are chosen for their durability and resistance to the high pressures and temperatures encountered in diesel engines. Additionally, the pump incorporates technological advancements that improve its efficiency and reliability, making it a suitable choice for heavy-duty applications.

Benefits of Using the 3972351 Fuel Injector Pump

Incorporating the 3972351 Fuel Injector Pump into heavy-duty trucks offers several advantages. One of the primary benefits is improved fuel efficiency, as the pump ensures that fuel is delivered under optimal conditions, reducing waste and enhancing combustion efficiency 4. This, in turn, contributes to enhanced engine performance, as the engine operates more smoothly and efficiently. Additionally, the reliability of the 3972351 Fuel Injector Pump ensures that trucks can operate under a wide range of conditions without experiencing fuel delivery issues.

Troubleshooting and Maintenance Suggestions

To ensure the optimal performance and longevity of the 3972351 Fuel Injector Pump, it is important to address common issues promptly. Regular maintenance practices, such as checking for leaks, ensuring proper fuel filter replacement, and monitoring fuel pressure, can help prevent issues. If problems arise, troubleshooting may involve checking the pump’s electrical connections, inspecting the fuel lines for blockages, and ensuring that the pump is receiving the correct voltage. Regular maintenance and prompt attention to issues can help maintain the pump’s performance and extend its lifespan.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s product range includes engines for on-highway and off-highway applications, as well as filtration and power generation solutions. Cummins’ contributions to diesel engine technology have played a significant role in advancing the efficiency and reliability of diesel engines in various applications.

Cummins Fuel Injector Pump 3972351 Compatibility with Engine Models

The Cummins Fuel Injector Pump part number 3972351 is a critical component in the operation of various diesel engines. This part is designed to deliver fuel to the engine’s combustion chambers with precision, ensuring optimal performance and efficiency.

Engine Models Compatible with 3972351

-

6B5.9 Series

- The 6B5.9 engine series is one of the prominent models that utilize the Cummins Fuel Injector Pump 3972351. This engine is known for its robust design and reliability, making it a popular choice in various industrial and commercial applications. The 3972351 pump is engineered to work seamlessly with the 6B5.9, ensuring that the engine operates at peak efficiency.

-

Other Cummins Engines

- While the 6B5.9 is a notable model, the 3972351 fuel injector pump is also compatible with other Cummins engine models. This versatility makes it a valuable component for technicians and fleet managers who need to maintain a wide range of diesel engines. The pump’s design allows it to fit into various engine configurations, providing a reliable solution for fuel delivery across different models.

Installation and Integration

The installation of the Cummins Fuel Injector Pump 3972351 is a straightforward process, designed to ensure that it integrates smoothly with the engine’s existing components. Here are some key points regarding the installation:

-

Compatibility Check

- Before installation, it is crucial to verify that the 3972351 pump is compatible with the specific engine model. This involves checking the engine’s specifications and ensuring that the pump’s design matches the engine’s requirements.

-

Mounting and Securing

- The pump is typically mounted onto the engine using specific mounting brackets and bolts. Proper alignment is essential to ensure that the pump operates correctly and does not cause undue stress on the engine components.

-

Fuel Line Connections

- The 3972351 pump is connected to the engine’s fuel lines, which deliver fuel from the tank to the pump and then to the injectors. Ensuring that these connections are secure and leak-free is critical for maintaining the engine’s performance.

-

Calibration and Testing

- After installation, the pump may require calibration to ensure that it delivers the correct amount of fuel at the appropriate pressure. This step is crucial for optimizing engine performance and preventing potential issues such as poor fuel efficiency or engine misfires.

By understanding the compatibility and installation process of the Cummins Fuel Injector Pump 3972351, technicians and fleet managers can ensure that their engines operate efficiently and reliably. This part’s versatility and precision make it an essential component for maintaining the performance of various Cummins engine models.

Role of Part 3972351 Fuel Injector Pump in Engine Systems

The part 3972351 Fuel Injector Pump is an integral component within the fuel system of an engine, ensuring precise and efficient fuel delivery. This pump works in conjunction with several other components to maintain optimal engine performance.

Interaction with the Fuel System

-

Fuel Tank: The pump draws fuel from the tank, where it is stored under pressure. This initial stage ensures a consistent supply of fuel to the engine.

-

Fuel Filter: Before the fuel reaches the injector pump, it passes through the fuel filter. This component removes impurities and contaminants, ensuring clean fuel is delivered to the pump.

-

Fuel Lines: The pump is connected to the fuel lines, which transport the pressurized fuel from the pump to the injectors. These lines must be robust and leak-free to maintain system integrity.

-

Fuel Injectors: The pressurized fuel from the pump is delivered to the fuel injectors. These injectors atomize the fuel into a fine mist, which is then injected into the combustion chamber at precise moments for optimal combustion.

Engine Performance Enhancement

-

Combustion Chamber: The atomized fuel mixes with air in the combustion chamber. The timing and pressure of fuel delivery, controlled by the pump, directly influence the combustion process and overall engine efficiency.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters and adjusts the fuel delivery accordingly. The pump must respond accurately to these signals to ensure the engine operates within its optimal range.

Maintenance and Efficiency

- Regular maintenance of the fuel injector pump, including checks for wear and tear, ensures consistent performance. Any deviation in pump efficiency can lead to decreased engine performance and increased fuel consumption.

Conclusion

In summary, the part 3972351 Fuel Injector Pump plays a significant role in the fuel delivery system, working seamlessly with other components to ensure efficient and reliable engine operation. Its precise fuel delivery, compatibility with various engine models, and the importance of regular maintenance contribute to the overall performance and efficiency of heavy-duty diesel engines.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Caines, Arthur J, Roger F Haycock, and John E Hillier. Automotive Lubricants Reference Book. SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.