This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

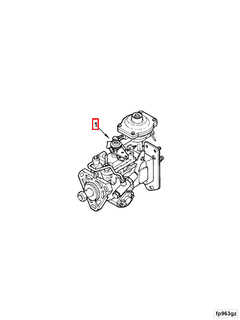

The Cummins 3974338 Fuel Injection Pump is a critical component in the operation of commercial trucks, especially those equipped with Cummins diesel engines. This part ensures the precise delivery of fuel to the engine cylinders, which is essential for efficient combustion and overall engine performance 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, the pump operates by creating high-pressure fuel that is injected into the cylinders at specific timings, optimizing combustion efficiency. Fuel injection systems can be mechanical or electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems use sensors and computer controls for more precise fuel management 2.

Purpose of the Cummins 3974338 Fuel Injection Pump

The Cummins 3974338 Fuel Injection Pump is designed to deliver fuel to the engine cylinders at precise timing and pressure. This ensures optimal combustion, which directly influences the engine’s power output, fuel efficiency, and emissions. The pump’s role is to maintain consistent fuel delivery under varying engine loads and speeds, contributing to the overall performance and reliability of the truck 3.

Key Features

The Cummins 3974338 Fuel Injection Pump is characterized by its robust design and construction, utilizing high-quality materials to ensure durability and performance. Key features include precision-machined components, advanced sealing technologies, and a design that enhances fuel delivery efficiency. These features contribute to the pump’s reliability and performance under demanding conditions.

Benefits

Utilizing the Cummins 3974338 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. These advantages contribute to lower operating costs and reduced maintenance requirements, making it a valuable component for commercial truck operators. The pump’s efficient fuel delivery also helps in reducing emissions, aligning with environmental regulations.

Installation and Integration

Proper installation and integration of the Cummins 3974338 Fuel Injection Pump within a truck’s engine system are crucial for optimal performance. It is important to follow manufacturer recommendations and procedures during installation to ensure compatibility and efficiency. This includes correct alignment, secure mounting, and proper connection to the fuel system.

Troubleshooting Common Issues

Common issues with the Cummins 3974338 Fuel Injection Pump may include leaks, misfires, or irregular engine performance. Troubleshooting these issues involves a systematic approach, starting with a visual inspection for leaks, checking fuel pressure, and examining the pump’s electrical connections. Solutions may range from tightening connections to replacing worn components or recalibrating the pump.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3974338 Fuel Injection Pump, regular maintenance is recommended. This includes periodic inspection for leaks, cleaning the pump and its components, and replacing worn or damaged parts as necessary. Adhering to the manufacturer’s maintenance schedule helps in preventing unexpected failures and ensures consistent engine performance.

Compatibility with Cummins Engines

The Cummins 3974338 Fuel Injection Pump is designed to be compatible with a range of Cummins engines, ensuring precise fuel delivery and optimal engine performance. This part is particularly suited for use in the 6B5.9 engine series, where it plays a crucial role in the engine’s fuel injection system. The compatibility of this part with the 6B5.9 engines is a testament to Cummins’ commitment to providing high-quality, reliable components that enhance engine performance.

Role of the 3974338 Fuel Injection Pump in Engine Systems

The 3974338 Fuel Injection Pump is an integral component within the engine system, working in concert with other parts to ensure optimal engine performance. Its primary function is to deliver precise amounts of fuel into the combustion chamber at the exact moment needed, which is essential for efficient combustion and power generation.

When the Fuel Injection Pump receives a signal from the engine control unit (ECU), it pressurizes the fuel and injects it through the fuel injectors. This process is synchronized with the engine’s intake cycle, ensuring that fuel is delivered at the precise moment for optimal air-fuel mixture.

The Fuel Injection Pump interacts closely with the fuel injectors, which are responsible for atomizing the fuel into a fine mist. This fine mist ensures that the fuel mixes thoroughly with the air, leading to more complete combustion and reduced emissions.

Additionally, the pump works in tandem with the fuel filter, which ensures that any contaminants in the fuel are removed before they can enter the injection system. This is vital for maintaining the integrity of the fuel injectors and the overall efficiency of the fuel delivery system.

The Fuel Injection Pump also plays a role in the feedback loop with the ECU. Sensors within the engine system, such as the oxygen sensor and the mass airflow sensor, provide data to the ECU about the air-fuel ratio and other parameters. The ECU uses this data to adjust the timing and amount of fuel delivered by the Fuel Injection Pump, ensuring that the engine operates within its optimal parameters under varying conditions.

Conclusion

The Cummins 3974338 Fuel Injection Pump is a vital component in the operation of commercial trucks, ensuring precise fuel delivery and optimal engine performance. Its robust design, compatibility with various Cummins engines, and integration within the engine system make it a critical part for maintaining efficiency, reliability, and compliance with environmental regulations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.