This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

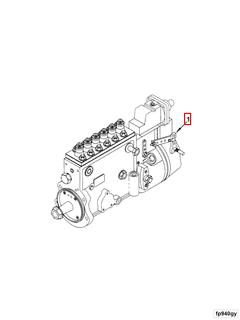

The Cummins Fuel Injection Pump Assembly, part number 3977352, is a significant component in the operation of commercial trucks. Cummins, a well-established name in the commercial vehicle industry, has designed this assembly to enhance the efficiency and performance of diesel engines. Understanding the role and functionality of this Cummins part is essential for maintaining and optimizing truck operations.

Basic Concepts of Fuel Injection Pump Assemblies

A Fuel Injection Pump Assembly is a vital part of a diesel engine’s fuel system. It is responsible for delivering pressurized fuel to the engine’s injectors, ensuring precise fuel delivery at the right time and in the correct amount. The assembly typically consists of several components, including the pump body, plungers, cam, and control mechanisms. These parts work together to regulate fuel flow, pressure, and timing, which are critical for efficient combustion and engine performance 1.

Role of the 3977352 Fuel Injection Pump Assembly in Truck Operation

The 3977352 Fuel Injection Pump Assembly plays a specific role in the fuel delivery system of a truck. It ensures that fuel is delivered to the engine’s injectors at the precise moment and pressure required for optimal combustion. This precise fuel delivery contributes to the engine’s performance and efficiency, allowing the truck to operate smoothly under various conditions. The assembly’s ability to maintain consistent fuel pressure and timing directly impacts the engine’s power output and fuel consumption 2.

Key Features of the 3977352 Fuel Injection Pump Assembly

The 3977352 Fuel Injection Pump Assembly is distinguished by its precision engineering and high-quality materials. Cummins has incorporated several technological features to enhance its performance and durability. These features include advanced metering systems, robust construction materials, and innovative design elements that ensure reliable operation even under demanding conditions. The assembly’s design allows for fine-tuning of fuel delivery, which contributes to improved engine efficiency and reduced emissions 3.

Benefits of Using the 3977352 Fuel Injection Pump Assembly

Using the 3977352 Fuel Injection Pump Assembly offers several advantages. One of the primary benefits is improved fuel efficiency, which translates to cost savings for truck operators. The assembly’s precise fuel delivery also enhances engine performance, providing consistent power output and smooth operation. Additionally, the high-quality construction and advanced features of the 3977352 model contribute to its reliability, reducing the likelihood of downtime and maintenance issues.

Troubleshooting Common Issues with Fuel Injection Pump Assemblies

Identifying and addressing common problems associated with Fuel Injection Pump Assemblies, including the 3977352 model, is important for maintaining optimal performance. Common issues may include irregular fuel delivery, decreased engine power, or increased fuel consumption. These problems can often be traced to worn components, incorrect timing, or contamination within the fuel system. Regular inspections and timely replacements of worn parts can help mitigate these issues.

Maintenance Practices for the 3977352 Fuel Injection Pump Assembly

To ensure the longevity and optimal performance of the 3977352 Fuel Injection Pump Assembly, regular maintenance practices are recommended. This includes periodic inspections to check for wear and tear, ensuring that all components are functioning correctly. Additionally, adhering to recommended service intervals for filter changes, fuel system cleaning, and component replacements can help maintain the assembly’s efficiency and reliability. Proper maintenance not only extends the life of the assembly but also contributes to overall engine performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for quality and innovation in the commercial vehicle industry. The company offers a wide range of products, including engines, powertrains, and related components, serving various markets such as transportation, construction, and power generation. Cummins’ commitment to excellence and customer satisfaction has solidified its position as a leader in the industry.

Compatibility and Installation

When installing the Cummins Fuel Injection Pump Assembly 3977352, it is essential to follow the manufacturer’s guidelines to ensure proper alignment and connection with the engine’s fuel system. This assembly is designed to fit precisely with the engine’s fuel lines and injectors, facilitating a straightforward installation process.

Performance and Reliability

The 3977352 Fuel Injection Pump Assembly is built to withstand the rigors of heavy-duty use, providing consistent performance and durability. Its design allows for precise control over fuel delivery, which is crucial for maintaining engine efficiency and reducing emissions.

Maintenance and Service

Regular maintenance of the Cummins Fuel Injection Pump Assembly is vital to ensure continued performance. This includes periodic inspections for leaks, wear, and proper operation. When servicing this component, it is recommended to use genuine Cummins parts to maintain the integrity and reliability of the engine system.

Role of Part 3977352 Fuel Injection Pump Assembly in Engine Systems

The Fuel Injection Pump Assembly, identified by part number 3977352, is integral to the operation of modern engine systems. This component is responsible for delivering precise amounts of fuel into the combustion chamber at the exact moment required for optimal engine performance.

When integrated into the engine system, the Fuel Injection Pump Assembly works in conjunction with several key components:

-

Injectors: The pump assembly supplies pressurized fuel to the injectors, which then atomize the fuel into the combustion chamber. This ensures a fine mist of fuel is delivered, promoting efficient combustion.

-

Fuel Rail: The assembly is connected to the fuel rail, which distributes fuel to each injector. The consistent pressure maintained by the pump ensures uniform fuel delivery across all cylinders.

-

ECU (Engine Control Unit): The ECU monitors various engine parameters and sends signals to the Fuel Injection Pump Assembly to adjust fuel delivery based on real-time data, such as engine load, speed, and temperature.

-

Sensors: Various sensors, including the mass airflow sensor, oxygen sensor, and throttle position sensor, provide feedback to the ECU, which in turn modulates the Fuel Injection Pump Assembly to maintain optimal fuel-air mixture.

-

Camshaft and Crankshaft: The mechanical linkage between the Fuel Injection Pump Assembly and the engine’s camshaft or crankshaft ensures that fuel delivery is synchronized with the engine’s piston movements.

-

Fuel Filter: Positioned upstream of the pump assembly, the fuel filter removes impurities from the fuel, ensuring that only clean fuel is delivered to the injectors, which prolongs the lifespan of the Fuel Injection Pump Assembly and injectors.

Conclusion

In summary, the Fuel Injection Pump Assembly (part 3977352) plays a significant role in the precise and efficient delivery of fuel within engine systems, working in harmony with a network of interconnected components to achieve optimal engine performance and efficiency.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Wang, Y. (2007). Introduction to Engine Valvetrains. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.