This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

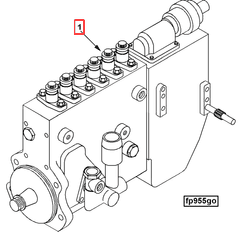

The Cummins 4058314 Fuel Injection Pump is a critical component for commercial trucks, designed to ensure efficient fuel delivery to diesel engines. This part is essential for maintaining the performance and reliability of heavy-duty engines.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes and delivers fuel to the engine cylinders in diesel engines. It draws fuel from the tank, pressurizes it, and injects it into the combustion chamber at precise moments in the engine cycle, which is vital for efficient fuel burning and power production 1.

Purpose of the Cummins 4058314 Fuel Injection Pump

This Cummins part is responsible for delivering fuel to the engine cylinders with exact timing and pressure, ensuring proper atomization upon injection for efficient combustion. It maintains correct fuel delivery parameters under varying engine loads and speeds, which is important for engine performance and fuel economy.

Key Features

The Cummins 4058314 Fuel Injection Pump features a robust design with high-quality materials to withstand heavy-duty use. It includes advanced technological features such as precise metering and timing mechanisms for accurate fuel delivery. The pump is also designed for easy maintenance and serviceability.

Benefits

This part offers improved fuel efficiency due to its precise fuel delivery. It enhances engine performance by ensuring optimal combustion and helps reduce emissions by promoting cleaner fuel burning, which is important for meeting environmental regulations.

Installation and Integration

Installing the Cummins 4058314 Fuel Injection Pump requires careful attention to the manufacturer’s guidelines for proper integration into the truck’s fuel system. This may include aligning the pump with the engine’s camshaft and ensuring all connections are secure and leak-free. Following recommended procedures is important to avoid issues with fuel delivery.

Troubleshooting and Maintenance

Common issues with this part may include leaks, inconsistent fuel delivery, or engine performance problems. Troubleshooting steps may involve checking for proper installation, inspecting for wear or damage, and ensuring all connections are tight. Regular maintenance practices, such as cleaning and inspecting the pump, can help prevent issues and ensure longevity.

Performance and Efficiency

The performance and efficiency of the Cummins 4058314 Fuel Injection Pump are evident in its ability to deliver fuel precisely when and where it is needed. This leads to better engine power output, reduced fuel consumption, and overall improved vehicle performance. The pump’s design optimizes the fuel injection process, contributing to these characteristics.

Cummins Overview

Cummins Inc. is a well-established company with a long history in the diesel engine industry. Known for its commitment to innovation and quality, Cummins has built a reputation for producing reliable and efficient engine components. The company’s focus on advancing diesel technology is evident in its product offerings, including the Cummins 4058314 Fuel Injection Pump.

Compatibility

The Cummins Fuel Injection Pump part number 4058314 is engineered to fit seamlessly with the following engines:

- 6B5.9: This engine is known for its robust performance and reliability. The 4058314 fuel injection pump ensures that the engine receives the correct amount of fuel at the right time, enhancing efficiency and power output.

When installing the 4058314 fuel injection pump, it is essential to ensure compatibility with the engine’s specifications. This involves checking the engine model, fuel system requirements, and any specific mounting or alignment considerations. Proper installation is crucial for maintaining the engine’s performance and longevity.

Role in Engine Systems

This part is integral to the efficient operation of modern engine systems. It works in concert with various components to ensure optimal fuel delivery and combustion.

Integration with the Fuel System

The Fuel Injection Pump (FIP) is the heart of the fuel system, responsible for pressurizing and delivering fuel to the injectors. It interfaces directly with the fuel tank, drawing in fuel through a series of filters that remove impurities. The FIP then pressurizes the fuel to the required levels before sending it to the fuel injectors.

Interaction with Fuel Injectors

Once pressurized, the fuel is distributed to the fuel injectors. The FIP ensures that each injector receives a consistent and precise amount of fuel. This precision is essential for maintaining the correct air-fuel ratio, which is vital for efficient combustion and engine performance.

Coordination with Engine Control Unit (ECU)

The FIP operates in tandem with the Engine Control Unit (ECU). The ECU monitors various engine parameters such as load, speed, and temperature. Based on this data, the ECU sends signals to the FIP to adjust the fuel delivery accordingly. This dynamic interaction ensures that the engine receives the optimal amount of fuel under varying conditions.

Role in Combustion Process

The efficiency of the FIP directly impacts the combustion process. By delivering fuel at the right pressure and timing, the FIP ensures that the fuel atomizes properly within the combustion chamber. This leads to more complete and efficient burning of the fuel, resulting in better engine performance and reduced emissions.

Maintenance of Fuel Pressure

The FIP also plays a role in maintaining consistent fuel pressure throughout the system. This is achieved through a series of pressure regulators and relief valves that are integrated into the pump. Consistent fuel pressure is essential for the reliable operation of the fuel injectors and overall engine performance.

Contribution to Engine Efficiency

By ensuring precise fuel delivery and maintaining optimal fuel pressure, the FIP contributes significantly to engine efficiency. This not only enhances performance but also improves fuel economy and reduces the overall environmental impact of the engine 2.

Conclusion

The Cummins 4058314 Fuel Injection Pump is a vital component in the operation of commercial diesel engines. Its robust design, precise fuel delivery, and integration with the engine’s fuel system ensure optimal performance, efficiency, and reliability. Proper installation, maintenance, and understanding of its role in the engine system are essential for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.