This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

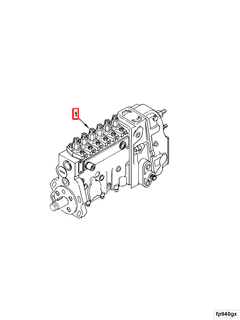

The Cummins 4093749 Fuel Injection Pump is a critical component in heavy-duty trucks, ensuring efficient fuel delivery to the engine. This part is essential for maintaining optimal performance and reliability in demanding applications, playing a significant role in diesel engine technology.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps operate by converting mechanical energy into hydraulic pressure to deliver fuel to engine cylinders at precise timing and pressure. This process is fundamental for efficient and effective diesel engine operation, influencing fuel atomization, combustion efficiency, and overall engine performance 1.

Purpose of the Cummins 4093749 Fuel Injection Pump

This Cummins part is engineered to deliver fuel to engine cylinders with precision, ensuring injection at the correct moment and pressure. Its role in the fuel delivery system is crucial for efficient combustion and engine performance in heavy-duty trucks 2.

Key Features

The Cummins 4093749 Fuel Injection Pump features a robust design and construction, utilizing high-quality materials for durability and reliability. It incorporates advanced technological features such as precision engineering and electronic control systems, enhancing performance and efficiency. These features ensure accurate and consistent fuel delivery under varying operating conditions 3.

Benefits

Utilizing this part offers advantages including improved fuel efficiency, enhanced engine performance, and increased reliability. Its precise fuel delivery capabilities contribute to more efficient combustion, leading to better fuel economy and reduced emissions. The pump’s durable construction and advanced features ensure long-term reliability and performance 4.

Troubleshooting and Maintenance

Common issues with this part may include fuel delivery inconsistencies, leaks, or mechanical failures. Troubleshooting involves checking for proper installation, inspecting for wear or damage, and ensuring adequate lubrication and cooling. Regular maintenance practices, such as cleaning and inspecting the pump and its components, can prevent issues and ensure optimal performance and longevity 5.

Integration with Cummins Engines

The Cummins 4093749 Fuel Injection Pump is designed to integrate seamlessly with Cummins diesel engines. Its compatibility ensures efficient and reliable fuel delivery, contributing to the overall performance and efficiency of the vehicle. Installation procedures are straightforward, and specific considerations for maintenance and repair are provided to ensure effective operation within the engine system 6.

Technological Advancements

This part incorporates technological advancements including precision engineering, electronic control systems, and durability enhancements. These advancements contribute to high accuracy and efficiency in fuel delivery, even in challenging operating conditions. The integration of electronic controls allows for precise adjustments to fuel delivery, further enhancing engine performance and efficiency 7.

Environmental Impact

The Cummins 4093749 Fuel Injection Pump contributes to reducing emissions and improving fuel efficiency in heavy-duty trucks. Its precise fuel delivery capabilities lead to more complete and efficient combustion, resulting in lower emissions and better fuel economy. This benefits the environment by reducing the carbon footprint of heavy-duty trucks and contributes to cost savings for operators through improved fuel efficiency 8.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines, natural gas engines, and related technologies. With a history of innovation and a commitment to sustainability, Cummins has made significant contributions to the diesel engine industry. The company’s focus on developing advanced technologies and solutions reflects its dedication to improving the efficiency, performance, and environmental impact of its products 9.

Compatibility

The Cummins Fuel Injection Pump part number 4093749 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of various applications, providing precise fuel delivery and efficient combustion.

Compatible Engines

-

4B3.9 Series: The 4093749 fuel injection pump is specifically engineered to integrate with the 4B3.9 engine series. This compatibility ensures that the pump can handle the unique requirements of these engines, delivering the necessary fuel pressure and timing for smooth operation.

-

Group Applications: In addition to the 4B3.9 series, the 4093749 fuel injection pump is also suitable for use in other engine groups where similar fuel delivery specifications are required. This versatility makes it a valuable component for a range of applications, enhancing the overall efficiency and performance of the engines it supports.

Each of these engines benefits from the precise engineering of the 4093749 fuel injection pump, ensuring that they operate at peak efficiency. The pump’s design allows for seamless integration with the engine’s fuel system, providing the necessary fuel delivery to meet the demands of various operational conditions.

Role in Engine Systems

The 4093749 Fuel Injection Pump is integral to the efficient operation of diesel engine systems. It works in conjunction with several key components to ensure optimal fuel delivery and combustion.

Interaction with the Fuel System

- Fuel Tank: The pump draws diesel fuel from the tank, initiating the fuel delivery process.

- Fuel Filter: Before reaching the injection pump, the fuel passes through a filter that removes impurities, ensuring clean fuel is delivered to the pump.

- Fuel Lines: These transport the filtered fuel from the tank to the injection pump and subsequently to the injectors.

Coordination with Engine Components

- Camshaft: The injection pump is often driven by the engine’s camshaft via a gear or chain drive. This synchronization ensures that fuel injection timing aligns with the engine’s piston movements.

- Injectors: The pump pressurizes the fuel and sends it to the injectors, which atomize the fuel into the combustion chamber at precise moments for efficient burning.

- Governor: This component regulates the pump’s output based on engine load and speed, maintaining consistent performance across varying conditions.

- Timing Mechanism: Ensures that the fuel injection occurs at the correct point in the engine cycle, optimizing combustion efficiency and power output.

Contribution to Engine Performance

- Combustion Efficiency: By delivering fuel at the right pressure and timing, the pump enhances combustion efficiency, leading to better fuel economy and reduced emissions.

- Power Delivery: Consistent and precise fuel injection results in smooth power delivery and improved engine responsiveness.

- Reliability: The pump’s role in maintaining proper fuel pressure and timing contributes to the overall reliability and longevity of the engine system.

Conclusion

The Cummins 4093749 Fuel Injection Pump is a vital component in the operation of heavy-duty trucks, ensuring efficient fuel delivery and combustion. Its robust design, advanced features, and compatibility with various engine models make it a reliable and efficient choice for diesel engine applications. Regular maintenance and proper integration with engine systems are key to maximizing its performance and longevity.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015

↩ -

Heavy Duty Truck Systems, Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing Limited, 2011

↩ -

Fundamentals of Automotive Technology Principles and Practice, Kirk T Van Gelder, Jones Bartlett Learning, 2018

↩ -

Service Manual (4358364), Cummins Inc.

↩ -

Service Manual (4358364), Cummins Inc.

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing Limited, 2011

↩ -

Fundamentals of Automotive Technology Principles and Practice, Kirk T Van Gelder, Jones Bartlett Learning, 2018

↩ -

Heavy Duty Truck Systems, Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.