This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

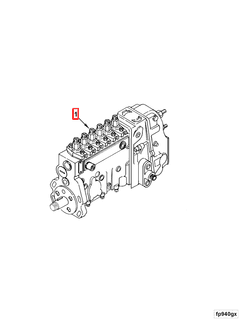

The Cummins 4093750 Fuel Injection Pump is a critical component in the operation of commercial trucks, ensuring the engine receives the precise amount of fuel needed for optimal performance, efficiency, and emissions control.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is designed to deliver fuel to the engine’s combustion chambers at the correct pressure and timing. In diesel engines, this component is essential for efficient fuel atomization and combustion. The pump operates by pressurizing fuel and injecting it into the engine cylinders at specific intervals, which are determined by the engine’s speed and load. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls for more precise fuel management 1.

Purpose of the Cummins 4093750 Fuel Injection Pump

This Cummins part is integral to the operation of a truck’s engine. It contributes to the engine’s performance by ensuring that fuel is delivered at the optimal pressure and timing. This precision enhances engine efficiency, improves power output, and helps in controlling emissions. The pump’s role in maintaining the correct fuel-air mixture is fundamental to the engine’s overall performance and longevity 2.

Key Features

The Cummins 4093750 Fuel Injection Pump boasts several key features that set it apart. Its design incorporates advanced technology to ensure reliable and efficient fuel delivery. Constructed from durable materials, this pump is built to withstand the rigors of commercial truck operation. Unique technological advancements, such as precision engineering and robust build quality, contribute to its effectiveness and longevity.

Benefits

Using the Cummins 4093750 Fuel Injection Pump offers several benefits. It enhances fuel efficiency by ensuring that fuel is delivered precisely when needed, reducing waste and improving overall economy. The pump also contributes to enhanced engine performance, providing consistent power output and smooth operation. Additionally, it helps in reducing emissions, ensuring compliance with environmental regulations, and increasing the reliability of the engine system 3.

Installation and Integration

Proper installation and integration of the 4093750 Fuel Injection Pump are crucial for its effective operation. Guidelines should be followed to ensure compatibility with various engine models and configurations. Careful attention to detail during installation will help prevent issues and ensure that the pump functions as intended within the engine system.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are essential for the longevity and optimal performance of the 4093750 Fuel Injection Pump. Common issues may include fuel delivery inconsistencies or pump wear. Best practices for maintenance include regular inspection intervals, cleaning, and following recommended service procedures to ensure the pump remains in top condition.

Performance and Efficiency

The Cummins 4093750 Fuel Injection Pump significantly contributes to the overall performance and efficiency of the truck. By ensuring precise fuel delivery, it enhances fuel economy and power output. The pump’s role in maintaining the correct fuel-air mixture is crucial for achieving optimal engine performance and efficiency.

Environmental Impact

The use of the Cummins 4093750 Fuel Injection Pump has positive environmental impacts. By ensuring efficient fuel combustion, it reduces harmful emissions, contributing to cleaner air. Compliance with environmental regulations is facilitated through the pump’s precise fuel delivery, which minimizes pollutants released into the atmosphere.

Cummins Corporation

Cummins Inc. is a renowned name in the automotive and diesel engine industry, with a rich history of innovation and quality. The company is committed to delivering reliable and high-performance engine components, including fuel injection pumps. Cummins’ reputation for excellence and customer satisfaction is built on a foundation of continuous innovation and a dedication to meeting the needs of its customers.

Compatibility with Specific Engine Models

The Cummins Fuel Injection Pump part number 4093750 is designed to integrate seamlessly with a range of Cummins engines, ensuring optimal performance and reliability. This part is engineered to meet the specific needs of various engine models, providing precise fuel delivery and efficient combustion.

- 4B3.9 Engines: The 4093750 fuel injection pump is specifically tailored to fit the 4B3.9 engine series. This engine model is known for its robust construction and high performance, making it a popular choice in various industrial applications. The pump’s design ensures that it can handle the demands of the 4B3.9 engine, delivering consistent fuel flow and enhancing overall engine efficiency.

Ensuring Optimal Performance

By using the Cummins Fuel Injection Pump 4093750, engine owners can expect improved fuel efficiency, reduced emissions, and enhanced engine longevity. The pump’s precision engineering ensures that it can deliver the exact amount of fuel required for optimal combustion, which is critical for maintaining engine performance and reliability.

Installation and Maintenance

Proper installation of the 4093750 fuel injection pump is crucial for ensuring its effectiveness. Technicians should follow the manufacturer’s guidelines for installation, which typically include steps for aligning the pump with the engine’s fuel system and securing it in place. Regular maintenance, such as checking for leaks and ensuring that the pump is functioning correctly, is also essential for prolonging the life of the pump and the engine it serves.

Role of Part 4093750 Fuel Injection Pump in Engine Systems

The part 4093750 Fuel Injection Pump is integral to the operation of modern engine systems, ensuring efficient and precise fuel delivery. This component works in concert with several other engine components to optimize performance, fuel efficiency, and emissions control.

Interaction with the Common Rail System

In engines equipped with a common rail fuel system, the Fuel Injection Pump plays a significant role. It pressurizes fuel and delivers it to the common rail, a high-pressure reservoir. From the common rail, fuel is distributed to individual injectors. The pump’s ability to maintain consistent pressure is essential for the injectors to operate correctly, ensuring that fuel is delivered at the right moment and in the right quantity.

Coordination with Fuel Injectors

The Fuel Injection Pump must be precisely synchronized with the fuel injectors. As the pump delivers pressurized fuel to the injectors, these components atomize the fuel into a fine mist, enhancing combustion efficiency. The timing and pressure of the fuel delivery directly influence the injectors’ performance, impacting overall engine efficiency and power output.

Integration with the Engine Control Unit (ECU)

Modern engines rely heavily on the Engine Control Unit (ECU) to manage various parameters, including fuel delivery. The ECU monitors engine conditions and adjusts the Fuel Injection Pump’s operation accordingly. Sensors provide real-time data on engine load, speed, and other factors, allowing the ECU to fine-tune the pump’s performance for optimal efficiency and emissions compliance.

Relationship with the High-Pressure Fuel System

The high-pressure fuel system, which includes components like the fuel filter, fuel lines, and pressure regulator, relies on the Fuel Injection Pump to maintain the necessary pressure levels. The pump ensures that fuel is consistently pressurized, allowing the high-pressure system to function effectively. This system is designed to handle the demands of modern engines, which require precise fuel delivery under varying conditions.

Contribution to Emissions Control

Effective operation of the Fuel Injection Pump is vital for meeting stringent emissions standards. By ensuring precise fuel delivery, the pump helps minimize unburned fuel and reduce harmful emissions. This is particularly important in diesel engines, where efficient combustion is essential for lowering nitrogen oxides (NOx) and particulate matter (PM) emissions.

Support from Ancillary Components

Ancillary components such as the fuel tank, fuel pump, and fuel return system also interact with the Fuel Injection Pump. The fuel tank stores the fuel, while the fuel pump delivers it to the injection pump. The fuel return system manages excess fuel, ensuring that the pump operates within its designed parameters. These components work together to support the pump’s function, maintaining the integrity of the fuel delivery system.

Conclusion

The Cummins 4093750 Fuel Injection Pump is a key component in modern engine systems, interacting with various elements to ensure efficient and precise fuel delivery. Its role in maintaining pressure, synchronizing with injectors, and supporting emissions control underscores its importance in the overall performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.