This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

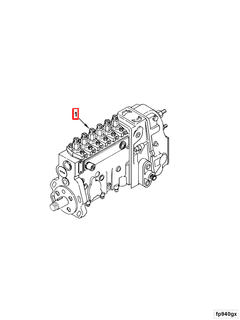

The Cummins 4093809 Fuel Injection Pump is a component designed for use in commercial trucks. It plays a role in the operation of these vehicles by ensuring that fuel is delivered to the engine cylinders at the correct timing and pressure. This part is integral to the efficient and reliable performance of diesel engines found in heavy-duty trucks.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine cylinders of a diesel engine. It operates by pressurizing fuel and injecting it into the combustion chamber at precise moments in the engine cycle. This process is vital for the efficient burning of fuel and the production of power. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls to optimize fuel injection based on real-time engine conditions 1.

Purpose and Function of the 4093809 Fuel Injection Pump

The Cummins 4093809 Fuel Injection Pump is designed to deliver fuel to the engine cylinders of a truck at precise timing and pressure. This ensures that the fuel is atomized correctly and burns efficiently, which contributes to the overall performance and fuel efficiency of the engine. The pump works in conjunction with other engine components to maintain optimal combustion conditions.

Key Features

The Cummins 4093809 Fuel Injection Pump features a robust design that includes high-quality materials to ensure durability and reliability. It incorporates advanced technological aspects such as precise metering and timing mechanisms that enhance its performance. The pump is engineered to withstand the demanding conditions of commercial truck operations, providing consistent fuel delivery under various load and speed conditions.

Benefits of Using the 4093809 Fuel Injection Pump

Utilizing the Cummins 4093809 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered at the optimal pressure and timing. This results in more complete combustion and reduced fuel consumption. Additionally, the pump enhances engine performance by providing consistent and precise fuel delivery, which can lead to increased power output and smoother operation. Furthermore, the efficient combustion facilitated by this pump can result in reduced emissions, aligning with environmental regulations and promoting sustainable operation 2.

Installation and Integration

When installing the Cummins 4093809 Fuel Injection Pump, it is important to follow the manufacturer’s recommendations to ensure proper integration into the truck’s engine system. This includes verifying that all connections are secure, the pump is correctly aligned, and that all necessary adjustments are made. Adhering to these guidelines helps to maintain the integrity of the fuel system and ensures the pump operates as intended.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 4093809 Fuel Injection Pump, regular maintenance is recommended. This includes checking for leaks, ensuring all connections are tight, and monitoring the pump for any signs of wear or damage. Common issues that may arise include inconsistent fuel delivery or engine performance problems. Troubleshooting steps may involve inspecting the pump for blockages, verifying the timing and pressure settings, and addressing any mechanical wear that may affect performance.

Performance and Efficiency

The Cummins 4093809 Fuel Injection Pump plays a role in the overall performance and efficiency of the truck by providing precise fuel delivery. The accuracy of fuel injection timing and pressure directly impacts the combustion process, influencing engine power, fuel economy, and emissions. Consistent and reliable fuel delivery ensures that the engine operates efficiently under a variety of conditions, contributing to the truck’s overall performance 3.

Safety Considerations

When working with the Cummins 4093809 Fuel Injection Pump, it is important to observe safety practices to prevent accidents and ensure personal safety. Potential hazards include high-pressure fuel lines and moving parts within the pump. To mitigate these risks, it is advisable to wear appropriate personal protective equipment, follow lockout/tagout procedures during maintenance, and ensure that all work is performed in a well-ventilated area to avoid fuel vapor accumulation.

Cummins Corporation

Cummins Inc. is a renowned manufacturer of diesel engines and components, with a history of innovation and quality in the industry. The company is committed to developing advanced technologies that enhance the performance, efficiency, and reliability of diesel engines. Cummins’ reputation is built on a foundation of engineering excellence and a dedication to meeting the needs of its customers in the commercial vehicle sector.

Compatibility

The Cummins Fuel Injection Pump part number 4093809 is designed to deliver precise fuel metering, ensuring optimal engine performance and efficiency. Below is a detailed description of its compatibility with various Cummins engines:

6B5.9 Engine Series

The Cummins Fuel Injection Pump 4093809 is specifically engineered to fit the 6B5.9 engine series. This engine is known for its robust design and reliability, making it a popular choice in various industrial and commercial applications. The 4093809 part number ensures that the fuel injection pump is perfectly aligned with the engine’s specifications, providing seamless integration and performance.

Grouping of Compatible Engines

While the 6B5.9 engine is the primary focus, it is important to note that the 4093809 fuel injection pump may also be compatible with other similar Cummins engine models. These engines often share common design elements and specifications, allowing for interchangeability of parts like the fuel injection pump. However, it is crucial to verify compatibility with the specific engine model before installation to ensure proper fit and function.

Importance of Correct Part Fitment

Using the correct fuel injection pump, such as the 4093809, is essential for maintaining engine performance and longevity. This part is designed to work in harmony with the engine’s fuel system, ensuring that fuel is delivered at the right pressure and timing. Incorrect part fitment can lead to inefficiencies, reduced performance, and potential engine damage.

Application in Industrial and Commercial Settings

The 4093809 fuel injection pump is widely used in industrial and commercial settings where reliability and performance are paramount. Its compatibility with the 6B5.9 engine series makes it a preferred choice for applications such as heavy machinery, generators, and other industrial equipment. The pump’s design ensures that it can handle the demands of these high-stress environments, providing consistent and dependable performance.

Role in Engine Systems

The Part 4093809 Fuel Injection Pump is an integral component within the engine system, ensuring precise fuel delivery to the combustion chambers. This pump works in concert with several other components to optimize engine performance and efficiency.

Interaction with the Fuel Pump

The Fuel Injection Pump, identified as Part 4093809, relies on the fuel pump to supply it with a consistent flow of fuel. The fuel pump draws fuel from the tank and pressurizes it before it reaches the injection pump. This pressurized fuel is essential for the injection pump to function correctly, as it needs a steady supply of fuel under pressure to deliver accurate amounts to each cylinder.

Fuel Delivery System

Once the fuel is pressurized by the fuel pump, it moves through the fuel lines to the Fuel Injection Pump. The pump then meters the fuel into precise quantities and injects it into the combustion chambers at the optimal moment in the engine cycle. This process is vital for maintaining the correct air-fuel ratio, which is necessary for efficient combustion and power output.

Engine Control Unit (ECU) Integration

The Fuel Injection Pump often communicates with the Engine Control Unit (ECU) to ensure that fuel delivery is synchronized with other engine operations. The ECU monitors various parameters such as engine load, RPM, and temperature to adjust the fuel injection timing and quantity. This integration allows for dynamic fuel management, enhancing both performance and fuel economy.

Injectors

The Fuel Injection Pump delivers fuel to the injectors, which are responsible for spraying atomized fuel into the combustion chambers. The precision of the pump ensures that each injector receives the exact amount of fuel needed for optimal combustion. This atomized fuel mixes more efficiently with the air, leading to a more complete burn and reduced emissions.

Overall Engine Performance

By ensuring that the correct amount of fuel is delivered at the right time, the Part 4093809 Fuel Injection Pump plays a role in the overall performance of the engine. It contributes to smooth operation, increased power output, and improved fuel efficiency. Additionally, it helps in reducing harmful emissions by ensuring that the fuel is burned as completely as possible.

Conclusion

The Cummins 4093809 Fuel Injection Pump is a critical component in the efficient operation of commercial trucks. Its precise fuel delivery system enhances engine performance, fuel efficiency, and reduces emissions. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.