This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

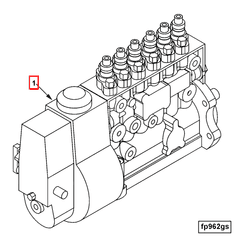

The Cummins 4938265 Fuel Injection Pump is a critical component for commercial trucks, ensuring efficient fuel delivery to the engine. This pump is essential for maintaining the performance and reliability of diesel engines.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump delivers fuel to the engine’s combustion chambers with precise timing and pressure. In diesel engines, this pump enhances combustion efficiency by atomizing the fuel 1. There are two main types of fuel injection systems: mechanical and electronic. Mechanical systems use physical components and cam-driven mechanisms, while electronic systems employ sensors and computer controls for more precise fuel injection 2.

Purpose of the Cummins 4938265 Fuel Injection Pump

The Cummins 4938265 is designed to deliver fuel at the correct timing and pressure, ensuring optimal combustion and contributing to engine performance and efficiency. It maintains consistent fuel delivery under varying engine loads and speeds, which is vital for the smooth operation of commercial trucks 3.

Key Features

This Cummins part features a robust design with precision-machined components for accurate fuel delivery. It incorporates advanced technology to enhance fuel atomization, improving combustion efficiency. Constructed with high-quality materials, it is built to withstand the demanding conditions of commercial truck operations. Specific adjustments for fuel delivery rates and pressure settings are tailored to Cummins engines.

Benefits

Using the Cummins 4938265 can lead to improved fuel efficiency and cost savings over time. It enhances engine performance by providing consistent and precise fuel delivery. Its reliable design helps maintain the engine’s durability and longevity.

Installation and Integration

Proper installation of this part involves careful alignment with the engine’s fuel system components. It may require specific adjustments to operate within the manufacturer’s specified parameters. Integration should follow Cummins guidelines to ensure compatibility and optimal performance.

Troubleshooting and Maintenance

Common issues with this part may include inconsistent fuel delivery or leaks. Troubleshooting often involves checking connections, seals, and internal components for wear or damage. Regular maintenance, such as cleaning and inspecting the pump, can help prevent issues and ensure optimal performance. Following the manufacturer’s maintenance schedule is recommended to prolong the pump’s service life.

Cummins Overview

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With a history of innovation, Cummins is committed to providing high-quality diesel engines and components. The company’s focus on research and development ensures that products like the 4938265 meet the demanding requirements of commercial applications.

Compatibility

The Cummins Fuel Injection Pump part number 4938265 is designed to integrate seamlessly with various engine models. It is crucial for efficient fuel delivery and performance. This part is compatible with the 6C8.3 engines and other Cummins engines within the same series, ensuring a perfect fit and optimal function.

Role in Engine Systems

The 4938265 Fuel Injection Pump is integral to the efficient operation of engine systems, particularly in diesel engines where precise fuel delivery is essential. This pump works with several key components to ensure optimal engine function.

Integration with the Fuel System

- Fuel Tank: Fuel is stored under pressure in the tank. The pump draws fuel from the tank via the fuel lines.

- Fuel Lines: These lines transport fuel from the tank to the pump. The integrity and cleanliness of these lines are vital to prevent contamination and ensure a consistent fuel supply.

- Fuel Filter: Fuel passes through a filter that removes impurities before reaching the pump. This step is essential to protect the pump from damage and ensure clean fuel delivery.

- Fuel Injection Pump (4938265): This component pressurizes the fuel and delivers it to the injectors at the precise moment needed. Its role is to atomize the fuel into a fine mist, which enhances combustion efficiency.

- Fuel Injectors: The pressurized fuel is delivered to these injectors, which spray it into the combustion chamber. The timing and quantity of fuel injection are controlled by the pump, influencing engine power and efficiency.

- Combustion Chamber: Within this chamber, the atomized fuel mixes with air and ignites, driving the piston downward and generating power.

- Exhaust System: The byproducts of combustion are expelled through the exhaust system, where emissions are controlled by various after-treatment devices.

Interaction with Engine Components

- Crankshaft: The power generated from the combustion process is transferred to the crankshaft, which converts linear motion into rotational motion.

- Camshaft: In some engine designs, the camshaft may control the timing of fuel injection, working in tandem with the Fuel Injection Pump to optimize performance.

- ECU (Engine Control Unit): Modern engines often incorporate an ECU that monitors and adjusts the operation of the Fuel Injection Pump in real-time, based on various sensor inputs to ensure optimal performance and emissions compliance.

Conclusion

The Cummins 4938265 Fuel Injection Pump is a pivotal component that ensures the precise delivery of fuel to the engine, interacting with a network of other components to maintain efficient and clean operation. Its robust design, advanced technology, and compatibility with various engine models make it an essential part for the performance and reliability of commercial trucks.

-

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.