This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

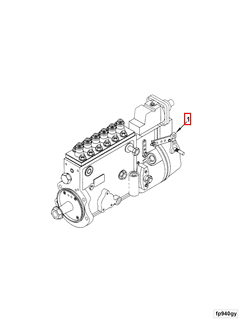

The Cummins 4939968 Fuel Injection Pump is a component designed for use in heavy-duty trucks. Its purpose is to deliver precise amounts of fuel to the engine’s combustion chambers at the correct pressure and timing. This precision is vital for the efficient operation of diesel engines, contributing to overall engine performance, fuel efficiency, and emissions control 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. It operates by using mechanical or electronic means to control the timing and amount of fuel injected. In diesel engines, the fuel injection pump plays a significant role in ensuring that fuel is delivered at the precise moment and in the exact quantity needed for optimal combustion. Mechanical fuel injection systems rely on engine-driven components to control fuel delivery, whereas electronic systems use sensors and a control unit to manage injection parameters more precisely 2.

Purpose and Role of the 4939968 Fuel Injection Pump

This Cummins part is specifically engineered to enhance the operation of heavy-duty trucks. It contributes to engine performance by ensuring that fuel is delivered under high pressure and at the correct timing, which is essential for efficient combustion. This precise fuel delivery helps improve fuel economy by maximizing the energy extracted from each fuel droplet. Additionally, it aids in emissions control by promoting cleaner combustion, which reduces the output of harmful pollutants 3.

Key Features

The 4939968 Fuel Injection Pump is characterized by its robust design and construction, utilizing high-quality materials to ensure durability and reliability. It incorporates advanced technological features such as precise metering and high-pressure delivery capabilities. These features are designed to meet the demanding requirements of heavy-duty truck applications, ensuring consistent performance under various operating conditions.

Benefits of Using the 4939968 Fuel Injection Pump

Utilizing this part offers several advantages. It contributes to improved fuel economy by optimizing fuel delivery for efficient combustion. Enhanced engine performance is another benefit, as the pump ensures that the engine receives the precise amount of fuel needed under all operating conditions. Additionally, it aids in reducing emissions, helping trucks meet environmental regulations and operate more cleanly.

Troubleshooting and Maintenance

Common issues with the 4939968 Fuel Injection Pump may include leaks, inconsistent fuel delivery, or failure to operate under certain conditions. Troubleshooting steps may involve checking for proper installation, inspecting for leaks, and ensuring that all connections are secure. Regular maintenance, such as cleaning or replacing filters and inspecting for wear, can help ensure the longevity and optimal performance of the pump.

Integration with Engine Management Systems

This Cummins part is designed to integrate seamlessly with modern engine management systems. It is compatible with various control strategies and diagnostic protocols, allowing for precise control over fuel delivery. This integration enhances the pump’s ability to adapt to different operating conditions and maintain optimal performance.

Historical Development and Technological Advancements

The development of fuel injection technology has evolved significantly, leading to the creation of advanced pumps like the 4939968. Technological advancements have focused on improving precision, reliability, and efficiency. These improvements have been driven by the need for better fuel economy, lower emissions, and enhanced engine performance in heavy-duty applications.

Cummins Corporation

Cummins Inc. is a leading manufacturer in the diesel engine and component industry, known for its commitment to innovation and quality. The company has a long history of developing reliable and efficient diesel engine components, including fuel injection pumps. Cummins’ reputation for excellence is built on its dedication to advancing technology and meeting the needs of its customers.

Application and Performance in Real-World Conditions

The 4939968 Fuel Injection Pump has been tested and proven in various real-world conditions, demonstrating its reliability and performance in heavy-duty truck applications. It operates effectively across different types of trucks and in diverse operating environments, ensuring consistent performance and efficiency.

Future Trends in Fuel Injection Technology

Emerging trends in fuel injection technology suggest continued advancements in efficiency, emissions control, and integration with alternative fuels. Future pumps may incorporate even more precise control over fuel delivery, further reduce emissions, and be compatible with a wider range of fuels. These developments aim to meet the evolving demands of the heavy-duty truck industry and environmental regulations.

Compatibility

This Cummins part is a critical component for several engine models, ensuring precise fuel delivery and optimal engine performance. It is designed to fit seamlessly into the following engines:

6B5.9 Series

- 6B5.9 Engine: The Cummins 6B5.9 engine is a robust and reliable power unit often used in various industrial and commercial applications. The 4939968 fuel injection pump is engineered to integrate perfectly with this engine, providing the necessary fuel metering and injection timing to maintain engine efficiency and power output.

Grouped Applications

- Industrial and Commercial Engines: The 4939968 fuel injection pump is also compatible with other industrial and commercial engines within the Cummins lineup. This part ensures that these engines receive the correct fuel delivery, which is crucial for maintaining performance and longevity.

- Heavy-Duty Applications: In heavy-duty applications, the 4939968 fuel injection pump is designed to handle the demanding conditions of continuous operation. Its compatibility with various Cummins engines ensures that these engines can deliver consistent power and efficiency, even under heavy loads.

The 4939968 fuel injection pump’s design and engineering make it a versatile and reliable choice for maintaining the performance of Cummins engines across different applications.

Role of 4939968 Fuel Injection Pump in Engine Systems

This part is an integral component within the fuel system of an engine, ensuring precise fuel delivery to the combustion chambers. Its role is to pressurize and inject fuel into the engine’s cylinders at the exact moment required for optimal combustion. This is achieved through a synchronized interaction with several key components within the engine system.

Interaction with Key Components

- Fuel Injectors: The Fuel Injection Pump delivers pressurized fuel to the fuel injectors. These injectors are responsible for spraying atomized fuel into the combustion chamber. The precise timing and amount of fuel injected are controlled by the pump, ensuring efficient combustion and power delivery.

- Fuel Rail: The pressurized fuel from the pump is channeled through the fuel rail, a distribution pipeline that supplies fuel to each injector. The fuel rail maintains a consistent pressure, allowing the injectors to operate effectively.

- Engine Control Unit (ECU): The ECU monitors various engine parameters and adjusts the operation of the Fuel Injection Pump accordingly. This ensures that the fuel delivery is optimized for the current engine load, speed, and environmental conditions.

- Sensors: Various sensors, such as the oxygen sensor, mass airflow sensor, and throttle position sensor, provide data to the ECU. This data helps the ECU make real-time adjustments to the fuel injection timing and quantity, enhancing engine performance and efficiency.

- Camshaft and Crankshaft: The Fuel Injection Pump often relies on signals from the camshaft and crankshaft position sensors to synchronize fuel injection with the engine’s piston movements. This ensures that fuel is injected at the precise moment for optimal combustion.

- Fuel Filter: Before reaching the Fuel Injection Pump, fuel passes through a fuel filter. This filter removes impurities and ensures that only clean fuel is pressurized and injected, protecting the injectors and other sensitive components from damage.

- Return Line: Excess fuel that is not injected into the cylinders is returned to the fuel tank via a return line. This helps maintain consistent fuel pressure within the system and prevents overheating of the fuel.

Through its interaction with these components, the 4939968 Fuel Injection Pump plays a significant role in ensuring that the engine operates efficiently, delivers optimal power, and meets emissions standards.

Conclusion

The Cummins 4939968 Fuel Injection Pump is a vital component in the fuel system of heavy-duty trucks, ensuring precise fuel delivery for optimal engine performance, fuel efficiency, and emissions control. Its robust design, advanced features, and compatibility with various engine models make it a reliable choice for maintaining the performance of Cummins engines across different applications. Regular maintenance and troubleshooting are essential to ensure the longevity and optimal performance of this part.

-

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.