This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

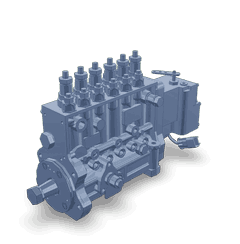

The Cummins Fuel Injection Pump Assembly, part number 4940749, is a significant component in heavy-duty trucks, playing a role in the fuel delivery system by ensuring that fuel is delivered to the engine cylinders at precise timing and pressure, which contributes to optimal engine performance and efficiency 1.

Basic Concepts of Fuel Injection Pump Assembly

Fuel injection pump assemblies operate on the principle of delivering pressurized fuel to the engine’s combustion chambers. In diesel engines, these assemblies are responsible for atomizing fuel into a fine mist, which enhances combustion efficiency. The pump works by drawing fuel from the tank, pressurizing it, and then injecting it into the cylinders at the exact moment required for combustion 2.

Purpose and Function of the Cummins Fuel Injection Pump Assembly

This Cummins part is designed to deliver fuel to the engine cylinders with precision. It ensures that the fuel is injected at the correct timing and pressure, which contributes to efficient combustion and engine performance. This assembly helps in maintaining the engine’s power output and fuel efficiency by ensuring that the fuel is delivered consistently and accurately 3.

Key Features of the Cummins Fuel Injection Pump Assembly

The Fuel Injection Pump Assembly boasts several key features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear and corrosion. The assembly includes advanced components such as precision-machined plungers and barrels, which ensure accurate fuel delivery. Additionally, it incorporates technological advancements like electronic control units (ECUs) that allow for fine-tuning of fuel injection parameters.

Benefits of Using the Cummins Fuel Injection Pump Assembly

Utilizing the Fuel Injection Pump Assembly offers several benefits. It contributes to improved fuel efficiency by ensuring that fuel is delivered at optimal pressure and timing. This results in more complete combustion and reduced fuel consumption. Furthermore, the assembly enhances engine performance by providing consistent and precise fuel delivery, which leads to smoother operation and increased power output. Reliability is also improved, as the high-quality construction and advanced components ensure durability and longevity.

Installation and Integration

When installing the Fuel Injection Pump Assembly, it is important to consider compatibility with various engine models. The assembly is designed to integrate seamlessly into existing fuel systems, but it is crucial to follow manufacturer guidelines to ensure proper installation. This includes verifying that all connections are secure and that the assembly is correctly aligned with the engine’s fuel lines and components.

Troubleshooting Common Issues

Common issues with fuel injection pump assemblies can include inconsistent fuel delivery, leaks, and performance declines. Diagnostic procedures involve checking for proper fuel pressure, inspecting for leaks, and ensuring that all components are functioning correctly. Recommended solutions may include cleaning or replacing worn components, recalibrating the injection timing, or addressing any leaks in the fuel lines.

Maintenance and Service Recommendations

To ensure the longevity and reliability of the Fuel Injection Pump Assembly, regular maintenance is recommended. This includes inspecting the assembly for signs of wear or damage, cleaning components to remove any buildup, and replacing any worn parts. Adhering to manufacturer-recommended inspection intervals and service procedures will help maintain optimal performance and prevent potential issues.

Cummins: A Brief Overview

Cummins Inc. is a renowned leader in the automotive industry, particularly in diesel engine technology. With a rich history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance engines and components. The company’s commitment to advancing diesel technology is evident in its extensive product portfolio, which includes a wide range of engines and fuel system components designed to meet the demanding needs of heavy-duty applications.

Cummins Fuel Injection Pump Assembly 4940749 Compatibility

The Cummins Fuel Injection Pump Assembly part number 4940749 is a component for the proper functioning of several engine models. This part is designed to ensure precise fuel delivery, which is essential for maintaining optimal engine performance and efficiency.

Engine Compatibility

- 6C8.3 Engines

- The 4940749 Fuel Injection Pump Assembly is specifically engineered to fit the 6C8.3 engine series. This engine is known for its reliability and robust performance, making it a popular choice in various applications. The compatibility of this part with the 6C8.3 engine ensures that the fuel injection system operates smoothly, contributing to the engine’s overall efficiency and longevity.

Grouping of Compatible Engines

- Cummins Engine Series

- The 4940749 part number is part of a broader range of Cummins fuel injection pump assemblies designed to fit various engine models. This grouping ensures that users can find the right component for their specific engine needs, facilitating easier maintenance and repair processes. The design consistency across these parts allows for seamless integration and reliable performance across different engine types.

Role of the Cummins Fuel Injection Pump Assembly in Engine Systems

The Cummins Fuel Injection Pump Assembly is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery, which is essential for optimal engine performance.

Interaction with the Fuel Pump

The Fuel Injection Pump Assembly interfaces directly with the fuel pump. The fuel pump is responsible for drawing fuel from the tank and delivering it to the injection pump under pressure. The injection pump then takes this pressurized fuel and further increases its pressure to the levels required for injection into the engine’s combustion chambers. This high-pressure fuel is then metered and timed for injection by the pump assembly, ensuring that the fuel is delivered at the precise moment for combustion.

Coordination with the Pump

In a broader sense, the term “pump” here can refer to any component involved in the movement of fuel within the system. This includes not only the primary fuel pump but also any secondary pumps or transfer pumps that might be present in more complex systems. The Fuel Injection Pump Assembly must be synchronized with these pumps to maintain a consistent fuel flow and pressure. This coordination ensures that the engine receives a steady supply of fuel, which is vital for maintaining engine performance under varying loads and speeds.

Fuel System Integration

Within the fuel system, the Fuel Injection Pump Assembly plays a significant role in regulating the amount of fuel that is injected into the engine. It works in tandem with fuel injectors, which are responsible for spraying the fuel into the combustion chambers. The precision with which the injection pump delivers fuel directly impacts the engine’s efficiency, power output, and emissions.

The assembly must also interact with various sensors and control units within the engine management system. These components monitor parameters such as engine speed, load, and temperature, and send signals to the injection pump to adjust the fuel delivery accordingly. This real-time feedback loop ensures that the engine operates within its optimal range, enhancing both performance and fuel economy.

Conclusion

In summary, the Cummins Fuel Injection Pump Assembly, part number 4940749, is a key player in the fuel delivery process, working in harmony with the fuel pump, other pumps within the system, and the overall fuel infrastructure to ensure that the engine receives the right amount of fuel at the right time. Its precise fuel delivery contributes to optimal engine performance, efficiency, and reliability.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.