This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

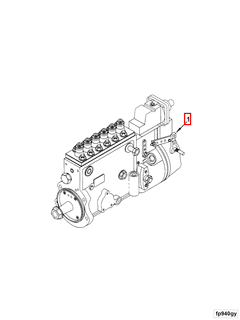

The Cummins 4981193 Fuel Injection Pump is designed for commercial trucks, enhancing diesel engine performance and efficiency. This mechanical pump ensures optimal fuel delivery for efficient combustion, power output, and fuel economy 2.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps pressurize and deliver fuel to engine combustion chambers at precise moments, crucial for diesel engine efficiency. Mechanical pumps, like the Cummins 4981193, use engine motion for fuel delivery, while electronic systems employ sensors and control units for more precise management 1.

Purpose of the Cummins 4981193 Fuel Injection Pump

This Cummins part delivers fuel at precise timing and pressure, ensuring efficient combustion, optimal engine performance, and fuel efficiency. Its ability to adjust fuel delivery based on engine demand is vital for maintaining performance across various conditions 2.

Key Features

The Cummins 4981193 is known for its robust design and high-quality materials, ensuring durability and reliability. It features advanced technology for precise fuel metering and efficient pressure regulation, meeting the demanding requirements of commercial truck engines 3.

Benefits

The Cummins 4981193 offers improved fuel efficiency, enhanced engine performance, and reduced emissions. Optimal fuel delivery maximizes engine efficiency and power output, contributing to lower emissions in compliance with environmental regulations 2.

Installation and Integration

Installing this part requires ensuring compatibility with the engine system and making necessary modifications. Proper installation is crucial for correct pump function and efficient engine operation 4.

Troubleshooting Common Issues

Common issues with fuel injection pumps include leaks, misfires, and irregular engine performance. Diagnostic steps involve checking for leaks, inspecting the pump for wear, and ensuring the fuel delivery system is clean. Solutions range from adjustments to component replacements 2.

Maintenance Tips

Regular maintenance practices, such as changing filters, conducting inspections for wear, and performing performance checks, are recommended to ensure the longevity and optimal performance of the Cummins 4981193 2.

Performance Enhancements

Potential upgrades or modifications to the Cummins 4981193 can improve engine performance. These may include tuning adjustments for optimized fuel delivery or replacing components for enhanced efficiency and reliability. Compatibility with the engine system should be carefully considered 2.

Cummins Corporation Overview

Cummins Inc. is a global leader in power solutions, including engines, filtration, and emissions control technologies. Known for its commitment to quality, innovation, and customer satisfaction, Cummins serves the commercial truck industry with a wide range of products 4.

Cummins Fuel Injection Pump 4981193 Compatibility

The Cummins Fuel Injection Pump 4981193 is engineered for compatibility with various engine models, ensuring optimal performance and reliability in heavy-duty applications.

Engine Compatibility

-

6B5.9 Series

- Specifically tailored for the 6B5.9 engine series, known for robust construction and high power output. The pump handles high-pressure requirements, contributing to engine efficiency and longevity 4.

-

Other Cummins Engines

- Compatible with other Cummins engines sharing similar design and operational parameters, allowing for easier maintenance and repair across multiple engine models 4.

Installation and Performance

-

Precision Engineering

- Manufactured with precision engineering for a perfect fit and reliable performance, delivering fuel with exact timing and pressure 3.

-

Durability

- Constructed from high-quality materials to resist wear and tear, ensuring long-term performance in demanding conditions 3.

-

Ease of Installation

- Straightforward installation process due to its standardized design, reducing downtime and maintenance costs 4.

Role of Part 4981193 Fuel Injection Pump in Engine Systems

The Cummins 4981193 Fuel Injection Pump is integral to the efficient operation of engine systems, particularly in diesel engines.

Integration with the Fuel System

- Fuel Tank: Fuel is stored in the fuel tank and drawn by the pump through fuel lines.

- Fuel Filter: Diesel passes through the fuel filter to remove impurities before reaching the pump.

- Fuel Lines: Clean fuel is transported via robust, leak-free fuel lines to the pump.

Operation within the Engine System

- Fuel Injection Pump: Pressurizes fuel for delivery at the precise moment and quantity required for combustion.

- Injectors: Pressurized fuel is sent to injectors, which spray it into the combustion chamber for efficient burning.

- Combustion Chamber: Atomized fuel mixes with air and ignites, driven by engine compression, generating power.

- Exhaust System: Combustion byproducts are expelled, with efficient fuel delivery minimizing unburnt fuel and reducing emissions.

Supporting Components

- Governor: Regulates fuel delivery by the pump, ensuring engine operation within designed parameters.

- Timing Mechanism: Ensures fuel is delivered at the correct moment in the engine cycle, often controlled by the engine’s camshaft or a dedicated timing gear.

- Sensors and Control Units: Modern engines may use sensors and electronic control units to monitor and adjust fuel delivery in real-time, enhancing efficiency and performance.

The Cummins 4981193 Fuel Injection Pump plays a significant role in the seamless operation of the engine system, ensuring efficient and effective fuel delivery to power the engine.

Conclusion

The Cummins 4981193 Fuel Injection Pump is a critical component in the operation of commercial truck diesel engines, offering improved efficiency, performance, and reduced emissions. Its robust design, precise engineering, and compatibility with various engine models make it a reliable choice for heavy-duty applications. Regular maintenance and proper installation are essential for ensuring optimal performance and longevity of this part.

-

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩ ↩ ↩ ↩ ↩ ↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ ↩ ↩ -

Cummins Inc. (n.d.). Service Manual (6307946) for B4.5 CM2220 B190B engines.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.