This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

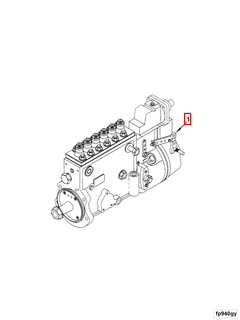

The Cummins 4988758 Fuel Injection Pump is a critical component in the operation of commercial trucks, ensuring that the engine receives the precise amount of fuel needed for optimal performance, efficiency, and emissions control. Understanding its function and importance is essential for maintaining and enhancing the performance of diesel-powered commercial vehicles.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is designed to deliver fuel to the engine’s combustion chambers at the correct pressure and timing. In diesel engines, this component is crucial for efficient combustion. The pump operates by pressurizing fuel and injecting it into the cylinders at precise moments in the engine cycle. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls for more precise fuel management 1.

Purpose of the Cummins 4988758 Fuel Injection Pump

The Cummins 4988758 Fuel Injection Pump ensures that fuel is delivered at the correct pressure and timing, which contributes to engine performance, fuel efficiency, and emissions control. By maintaining consistent fuel delivery, this part helps to optimize the combustion process, leading to smoother engine operation and reduced emissions 2.

Key Features

This Cummins part is characterized by its robust design and high-quality construction materials. It incorporates advanced technological features such as precision-machined components and durable materials to ensure reliable performance. The pump’s design allows for efficient fuel delivery and is built to withstand the demanding conditions of commercial truck operation 3.

Benefits

Using the Cummins 4988758 Fuel Injection Pump offers several benefits. These include improved fuel economy due to precise fuel delivery, enhanced engine performance through optimized combustion, reduced emissions as a result of efficient fuel use, and increased reliability thanks to its durable construction. These advantages make it a valuable component for commercial truck operators 4.

Installation and Integration

Proper installation of the Cummins 4988758 Fuel Injection Pump is crucial for ensuring compatibility with the truck’s engine system. It is important to follow manufacturer guidelines to integrate the pump correctly. Considerations should be given to the compatibility of the pump with other engine components to ensure seamless operation and optimal performance 5.

Troubleshooting Common Issues

Common problems associated with fuel injection pumps include poor engine performance, irregular idling, and fuel delivery issues. Troubleshooting these problems involves checking for leaks, ensuring proper fuel pressure, and inspecting the pump and related components for wear or damage. Diagnostic tools and procedures can help identify specific issues and guide the repair process 6.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the Cummins 4988758 Fuel Injection Pump. This includes routine inspections, cleaning of components, and replacement of wear parts as needed. Adhering to a maintenance schedule helps prevent issues and ensures the pump operates efficiently 7.

Performance Enhancements

There are opportunities for performance enhancements and upgrades to the Cummins 4988758 Fuel Injection Pump. Aftermarket options and tuning possibilities can further optimize fuel delivery and engine performance. These enhancements should be approached with caution and ideally performed by qualified professionals to ensure compatibility and safety 8.

Cummins Corporation

Cummins Inc. is a renowned name in the commercial truck industry, known for its innovative diesel engine technology and commitment to quality. The company offers a wide range of products designed to meet the needs of various industries. Cummins’ reputation for reliability and performance is built on a history of technological advancement and customer-focused solutions 9.

Cummins Fuel Injection Pump 4988758 Compatibility

The Cummins Fuel Injection Pump part number 4988758 is a critical component for several engine models, ensuring precise fuel delivery and optimal engine performance. This part is engineered to fit seamlessly with various Cummins engines, providing reliable and efficient operation.

Engine Compatibility

-

6B5.9 Series

- The 4988758 fuel injection pump is specifically designed to integrate with the 6B5.9 engines. This engine is known for its robust performance and is widely used in various industrial and commercial applications.

-

Group Compatibility

- The 4988758 part number is also compatible with other engines within the same series, ensuring a standardized fit across multiple engine models. This compatibility allows for easier maintenance and replacement, reducing downtime and ensuring consistent engine performance.

Installation and Performance

-

Precision Engineering

- The Cummins Fuel Injection Pump 4988758 is crafted with precision engineering to deliver accurate fuel metering. This ensures that the engine operates at peak efficiency, maintaining power output and fuel economy.

-

Durability

- Built to withstand the rigors of heavy-duty use, the 4988758 fuel injection pump is designed for durability and longevity. This makes it a reliable choice for operators who demand consistent performance from their engines.

-

Ease of Integration

- The integration process for the 4988758 fuel injection pump is straightforward, allowing for quick and efficient installation. This ease of integration minimizes the time required for maintenance, helping to keep operations running smoothly.

Application in Various Industries

-

Industrial Use

- The 4988758 fuel injection pump is ideal for industrial applications where reliability and performance are paramount. It is used in machinery and equipment that require consistent power output and minimal downtime.

-

Commercial Applications

- In commercial settings, such as transportation and logistics, the 4988758 fuel injection pump ensures that engines perform reliably under varying conditions. This is crucial for maintaining schedules and meeting operational demands.

By ensuring a precise fit and reliable performance, the Cummins Fuel Injection Pump 4988758 is an essential component for the engines it supports, providing the necessary fuel delivery to maintain optimal engine operation.

Role of Part 4988758 Fuel Injection Pump in Engine Systems

The part 4988758 Fuel Injection Pump is integral to the efficient operation of diesel engine systems. It works in conjunction with several key components to ensure optimal fuel delivery and combustion.

Interaction with the Fuel System

- Fuel Tank: The pump draws diesel fuel from the tank, initiating the fuel delivery process.

- Fuel Filter: Before reaching the pump, fuel passes through a filter that removes impurities, ensuring clean fuel is delivered to the pump.

- Fuel Lines: These transport the filtered fuel from the tank to the pump and subsequently to the injectors.

Coordination with Engine Components

- Injectors: The pump pressurizes fuel and sends it to the injectors, which atomize the fuel into the combustion chamber.

- Combustion Chamber: Pressurized fuel is injected into the chamber, where it mixes with air and ignites, driving the pistons.

- Pistons and Cylinders: The combustion process pushes the pistons down, converting chemical energy into mechanical work.

- Crankshaft: Movement of the pistons is transferred to the crankshaft, which converts linear motion into rotational motion to drive the vehicle.

Integration with Control Systems

- Engine Control Unit (ECU): The ECU monitors various parameters and adjusts the pump’s operation to optimize fuel delivery based on driving conditions.

- Sensors: Components like the camshaft position sensor and crankshaft position sensor provide data to the ECU, allowing for precise control of the injection timing.

- Governor: In some systems, a mechanical governor regulates the pump’s output based on engine speed and load.

Maintenance and Performance

Regular maintenance of the fuel injection pump, including inspection of fuel lines, filters, and injectors, ensures consistent performance and efficiency. Proper lubrication and sealing of the pump components are also essential to prevent leaks and ensure smooth operation.

Conclusion

The Cummins 4988758 Fuel Injection Pump plays a vital role in the efficient operation of diesel engines. Its precise fuel delivery ensures optimal engine performance, fuel efficiency, and emissions control. Proper installation, regular maintenance, and understanding its interaction with other engine components are crucial for maximizing the benefits of this part. Cummins’ commitment to quality and innovation ensures that this fuel injection pump remains a reliable and essential component for commercial truck operators.

-

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩ -

Kershaw, J. F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ -

Cummins Inc. (2023). Operation and Maintenance Manual for X15 CM2350 X130C. Bulletin Number 5504561.

↩ -

Cummins Inc. (2023). Operation and Maintenance Manual for X15 CM2350 X130C. Bulletin Number 5504561.

↩ -

Cummins Inc. (2023). Operation and Maintenance Manual for X15 CM2350 X130C. Bulletin Number 5504561.

↩ -

Cummins Inc. (2023). Operation and Maintenance Manual for X15 CM2350 X130C. Bulletin Number 5504561.

↩ -

Cummins Inc. (2023). Operation and Maintenance Manual for X15 CM2350 X130C. Bulletin Number 5504561.

↩ -

Cummins Inc. (2023). Operation and Maintenance Manual for X15 CM2350 X130C. Bulletin Number 5504561.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.