This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

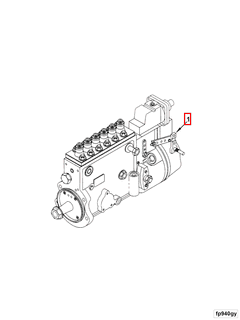

The Cummins 4994276 Fuel Injection Pump is a critical component in the operation of heavy-duty trucks. It ensures that the engine receives the precise amount of fuel at the correct timing and pressure, enhancing performance and efficiency. This part is designed to improve the reliability and power output of diesel engines.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is responsible for delivering fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the engine at specific intervals, determined by the engine’s speed and load. In diesel engines, the fuel injection pump ensures efficient combustion and optimal engine performance. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms, whereas electronic systems use sensors and computer controls for more precise fuel injection 1.

Purpose of the Cummins 4994276 Fuel Injection Pump

The Cummins 4994276 Fuel Injection Pump is designed to deliver fuel to the engine at precise timing and pressure. It ensures that fuel is injected into the combustion chambers at the optimal moment, which is essential for efficient combustion and engine performance. This pump helps maintain the engine’s power output and fuel efficiency by providing consistent and accurate fuel delivery 2.

Key Features

The Cummins 4994276 Fuel Injection Pump features high-quality materials to withstand heavy-duty use. It includes technological advancements such as improved seals and precision-machined components to ensure accurate fuel delivery and reduce the likelihood of leaks or malfunctions.

Benefits

The Cummins 4994276 Fuel Injection Pump offers several benefits, including improved fuel efficiency by ensuring precise fuel delivery for optimal combustion. This results in enhanced engine performance and increased reliability. The pump’s design also helps reduce emissions, making it an environmentally friendly choice for fleet operators 3.

Installation and Integration

Installing the Cummins 4994276 Fuel Injection Pump requires ensuring compatibility with the truck’s engine and fuel system. Any necessary modifications or adjustments should be made according to the manufacturer’s guidelines to ensure proper integration and function. Following the installation instructions carefully will help avoid potential issues and ensure efficient operation.

Troubleshooting Common Issues

Common problems associated with the Cummins 4994276 Fuel Injection Pump include leaks, misfires, and irregular idling. These issues can often be traced to worn components, improper installation, or contamination within the fuel system. Troubleshooting steps may involve inspecting the pump for signs of wear, checking the fuel lines for leaks, and ensuring that the fuel filter is clean and functioning correctly. Addressing these issues promptly can help maintain the pump’s performance and longevity.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the Cummins 4994276 Fuel Injection Pump. This includes conducting regular inspections to check for signs of wear or damage, cleaning the pump and fuel system components to prevent contamination, and replacing worn parts as needed. Adhering to a maintenance schedule will help prevent unexpected failures and ensure the pump continues to operate efficiently.

Cummins Company Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to innovation and quality. The company has a long history of producing reliable and high-performance diesel engines and components, including fuel injection systems. Cummins’ reputation for excellence is built on its dedication to research and development, ensuring that its products meet the demanding requirements of heavy-duty applications 4.

Compatibility

The Cummins Fuel Injection Pump part number 4994276 is designed to be compatible with a range of Cummins engines, ensuring efficient fuel delivery and performance. This part is engineered to fit seamlessly with various engine models, providing reliable operation and longevity.

Compatible Engines

-

6B5.9 Series: The 4994276 fuel injection pump is specifically engineered to fit the 6B5.9 engines. This compatibility ensures that the pump meets the unique requirements of these engines, enhancing fuel efficiency and power output.

-

Other Cummins Engines: While the primary focus is on the 6B5.9 series, the 4994276 fuel injection pump is also compatible with other Cummins engines. This versatility makes it a valuable component for maintaining and upgrading various engine models within the Cummins lineup.

Engine Group Compatibility

-

Industrial Engines: The 4994276 fuel injection pump is suitable for industrial engines that require robust and dependable fuel delivery systems. This makes it an ideal choice for heavy machinery and industrial applications where performance and reliability are critical.

-

Commercial Engines: This fuel injection pump is also well-suited for commercial engines, providing the necessary precision and efficiency for a wide range of commercial vehicles and equipment. Its compatibility with various engine models ensures that it can be used across different commercial applications.

Role of Part 4994276 Fuel Injection Pump in Engine Systems

The fuel injection pump, specifically part 4994276, is integral to the efficient operation of engine systems. This component works in concert with several other parts to ensure optimal fuel delivery and combustion.

Interaction with the Fuel System

The fuel injection pump is responsible for pressurizing fuel and delivering it to the injectors. It interfaces directly with the fuel tank, fuel lines, and fuel filters. The pressurized fuel is then routed through the fuel rails to the injectors, which atomize the fuel into the combustion chambers.

Coordination with Injectors

Once the fuel reaches the injectors, the pump’s precise control over fuel pressure and timing becomes apparent. The injectors rely on consistent pressure from the pump to deliver the correct amount of fuel at the right moment. This synchronization is vital for maintaining engine performance and fuel efficiency.

Integration with the Engine Control Unit (ECU)

The fuel injection pump operates under the supervision of the Engine Control Unit (ECU). The ECU monitors various parameters such as engine speed, load, and air intake to adjust the fuel delivery. Sensors provide real-time data to the ECU, which then sends signals to the pump to modulate fuel pressure and flow.

Relationship with the Combustion Process

Efficient combustion is dependent on the proper air-fuel mixture, which the fuel injection pump helps to achieve. By delivering fuel in a highly atomized state, the pump ensures that the fuel mixes thoroughly with the air in the cylinders. This leads to more complete combustion, reducing emissions and improving power output.

Impact on Engine Performance

The performance of the fuel injection pump directly influences engine responsiveness, power delivery, and overall drivability. A well-functioning pump ensures that the engine receives a consistent supply of fuel, which is essential for smooth operation across all RPM ranges.

Maintenance and Diagnostics

Regular maintenance of the fuel injection pump is essential to prevent issues such as fuel starvation, misfires, or reduced engine performance. Diagnostic tools can monitor the pump’s operation, allowing for early detection of potential problems.

Conclusion

In summary, the Cummins 4994276 Fuel Injection Pump plays a significant role in the engine’s fuel delivery system, working in harmony with injectors, the ECU, and other components to ensure efficient and reliable engine operation. Regular maintenance and proper installation are crucial to maximizing the performance and longevity of this part.

-

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, Simon Baseley, SAE International, 2014

↩ -

Heavyduty Electric Vehicles: From Concept to Reality, Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Elsevier, 2021

↩ -

Gasoline Engine Management Systems and Components, Konrad Reif, Springer Vieweg, 2015

↩ -

The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Giancarlo Genta and Lorenzo Morello, Springer, 2019

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.