This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4359490 Fuel Pump is a component designed for use in commercial trucks. It serves the purpose of delivering fuel from the tank to the engine, ensuring that the engine receives the necessary fuel for combustion. This part is significant in the operation of commercial trucks as it contributes to the overall efficiency and performance of the vehicle.

Basic Concepts of Fuel Pumps

A fuel pump is a device that moves fuel from the fuel tank to the engine. It plays a role in the engine system by ensuring a consistent supply of fuel under pressure, which is necessary for efficient combustion. There are different types of fuel pumps, including mechanical, electric, and high-pressure pumps, each suited to specific engine requirements and designs 1.

Role of the Cummins 4359490 Fuel Pump in Truck Operation

The Cummins 4359490 Fuel Pump contributes to the efficient operation of a truck by delivering fuel at the required pressure and volume to the engine. This ensures that the engine operates smoothly and efficiently. The pump’s role in fuel delivery directly impacts engine performance, as consistent and adequate fuel supply is crucial for optimal engine function.

Key Features of the Cummins 4359490 Fuel Pump

The Cummins 4359490 Fuel Pump is characterized by its robust design and the use of high-quality materials, which contribute to its durability and reliability. It incorporates advanced technological aspects that enhance its performance and efficiency. The pump is engineered to withstand the demanding conditions of commercial truck operations.

Benefits of Using the Cummins 4359490 Fuel Pump

The Cummins 4359490 Fuel Pump offers several advantages, including enhanced reliability, improved efficiency, and increased durability. Its design and construction ensure consistent performance under various operating conditions, contributing to the overall efficiency of the truck’s fuel system.

Installation and Integration

Proper installation and integration of the Cummins 4359490 Fuel Pump within a truck’s fuel system are important for ensuring optimal performance. Guidelines for installation include ensuring a secure fit, proper alignment, and correct electrical connections. Integration involves connecting the pump to the fuel lines and ensuring it operates within the specified parameters of the truck’s fuel system.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4359490 Fuel Pump is important for ensuring its longevity and performance. This includes regular checks for leaks, cleaning the pump and its components, and troubleshooting common issues such as inconsistent fuel delivery or pump failure. Adhering to a maintenance schedule can help prevent issues and ensure the pump operates efficiently.

Performance and Efficiency

The Cummins 4359490 Fuel Pump impacts the overall performance and fuel efficiency of a truck by ensuring a consistent and adequate supply of fuel to the engine. Its efficient operation contributes to the truck’s fuel economy and overall performance, making it a valuable component in the vehicle’s fuel system.

Safety Considerations

When working with the Cummins 4359490 Fuel Pump, it is important to observe safety practices and precautions. This includes ensuring the fuel system is depressurized before working on the pump, using appropriate personal protective equipment, and following manufacturer guidelines for installation, maintenance, and troubleshooting.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications 2.

Cummins Fuel Pump 4359490 Compatibility

The Cummins Fuel Pump part number 4359490 is designed to fit seamlessly within a range of Cummins engines, ensuring optimal fuel delivery and engine performance. This fuel pump is engineered to meet the specific requirements of various Cummins engine models, providing reliable and efficient operation.

ISX12 and CM2350 Engines

The Cummins Fuel Pump 4359490 is compatible with the ISX12 and CM2350 engines. These engines are known for their robust performance and are often used in heavy-duty applications. The fuel pump is engineered to handle the high-pressure demands of these engines, ensuring consistent fuel flow and maintaining engine efficiency.

X102 Engine

The X102 engine also benefits from the use of the Cummins Fuel Pump 4359490. This engine is typically used in a variety of applications, including agricultural and industrial machinery. The fuel pump’s design ensures it can deliver the precise amount of fuel required by the X102 engine, enhancing overall performance and reliability.

Installation and Integration

The Cummins Fuel Pump 4359490 is designed for straightforward installation across the compatible engine models. It integrates seamlessly with the engine’s fuel system, ensuring that it works in harmony with other components. This compatibility is crucial for maintaining the engine’s performance and longevity.

Performance and Reliability

The use of the Cummins Fuel Pump 4359490 in the ISX12, CM2350, and X102 engines ensures that these engines receive the necessary fuel supply to operate efficiently. The pump’s design and engineering focus on reliability, reducing the likelihood of fuel delivery issues and enhancing overall engine performance.

Role of Part 4359490 Fuel Pump in Engine Systems

The part 4359490 Fuel Pump is integral to the operation of the XPI JV System in Cummins HD engines. This pump is responsible for delivering fuel from the tank to the high-pressure system, ensuring a consistent and reliable fuel supply.

In the XPI (X-Series Pump Injection) system, the fuel pump works in conjunction with the high-pressure pump to maintain the necessary fuel pressure for efficient combustion. The JV (Joint Venture) system, a collaboration between Cummins and other manufacturers, relies on this fuel pump to deliver precise fuel metering.

The fuel pump interfaces with the fuel rail, which distributes fuel to the injectors. It also connects to the fuel filter, ensuring that clean fuel is delivered to the high-pressure system. The pump’s performance directly influences the injectors’ ability to atomize fuel effectively, which is essential for optimal engine performance and emissions control.

Additionally, the fuel pump is linked to the engine control unit (ECU), which monitors and adjusts fuel delivery based on engine load, speed, and other operating conditions. This integration ensures that the fuel system operates within specified parameters, enhancing overall engine efficiency and reliability.

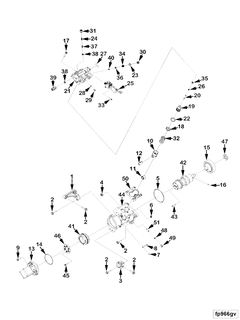

Components of Cummins Fuel Pump Kit 4359490

Fuel Pump Assembly

The fuel pump assembly is the core component of the kit. It is responsible for drawing fuel from the tank and delivering it to the engine at the required pressure. This assembly includes the pump mechanism, which may be mechanical or electric, and is designed to ensure consistent fuel delivery under varying engine loads and conditions.

Fuel Filter

The fuel filter is a critical component that removes impurities and contaminants from the fuel before it reaches the engine. This ensures that the fuel entering the engine is clean, which is essential for maintaining engine performance and longevity. The filter is typically a replaceable cartridge that can be easily installed or removed as part of routine maintenance.

Fuel Lines

Fuel lines are the conduits that transport fuel from the tank to the fuel pump and from the fuel pump to the engine. These lines are made from durable materials that can withstand the pressure and temperature of the fuel system. They are designed to be flexible yet robust, ensuring a secure and leak-free connection throughout the fuel delivery system.

Gaskets and Seals

Gaskets and seals are used throughout the fuel pump kit to ensure that all connections are tight and leak-free. These components are crucial for maintaining the integrity of the fuel system, preventing fuel leaks, and ensuring that the system operates efficiently. They are typically made from materials that can withstand the chemical properties of fuel.

Mounting Bracket

The mounting bracket is used to secure the fuel pump assembly to the vehicle’s frame or another suitable location. This bracket ensures that the pump is stable and properly aligned, which is important for the efficient operation of the fuel system. It is designed to be durable and resistant to the vibrations and stresses encountered during vehicle operation.

Electrical Connectors

For electric fuel pumps, electrical connectors are included to link the pump to the vehicle’s electrical system. These connectors ensure a secure and reliable electrical connection, which is vital for the pump’s operation. They are designed to be weather-resistant and capable of withstanding the rigors of the underhood environment.

Pressure Regulator

The pressure regulator is a component that maintains the fuel pressure within the specified range required by the engine. This ensures that the engine receives the correct amount of fuel at all times, which is critical for optimal performance and fuel efficiency. The regulator may be integrated into the fuel pump assembly or provided as a separate component.

Check Valve

The check valve prevents fuel from flowing backward in the fuel system, which can occur when the engine is turned off. This helps to maintain fuel pressure in the system, ensuring that the engine starts easily and runs smoothly. The check valve is a simple yet essential component for the proper functioning of the fuel pump system.

O-Rings

O-rings are used in various connections throughout the fuel pump kit to create a seal that prevents leaks. These small but crucial components are made from materials that can withstand fuel and provide a reliable seal under pressure. They are often used in conjunction with gaskets to ensure the integrity of the fuel system.

Instructions and Hardware

The kit includes detailed instructions for installation and any necessary hardware such as bolts, nuts, and clips. These components ensure that the fuel pump is properly installed and secured, which is important for the safety and reliability of the fuel system. The instructions are designed to be clear and easy to follow, even for those with limited mechanical experience.

Conclusion

The Cummins 4359490 Fuel Pump is a critical component in the fuel system of commercial trucks, ensuring efficient and reliable fuel delivery to the engine. Its robust design, advanced features, and compatibility with various Cummins engines make it a valuable asset for maintaining optimal engine performance and fuel efficiency. Proper installation, regular maintenance, and adherence to safety practices are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.