This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

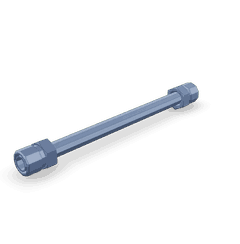

The Fuel Supply Tube 3087766, a component designed by Cummins, is integral to the fuel system of heavy-duty trucks. This tube ensures the efficient transfer of fuel from the tank to the engine, reflecting Cummins’ commitment to innovation and quality in diesel engine technologies 1.

Purpose and Function

This Cummins part facilitates the transfer of fuel from the tank to the engine, ensuring a consistent fuel delivery. This consistency is vital for maintaining engine performance and achieving stable engine operation 2.

Key Features

The Fuel Supply Tube 3087766 is constructed from materials such as metal or high-durability plastic, chosen for their strength and resistance to harsh conditions. Its design may include reinforced sections to withstand pressure fluctuations and corrosion-resistant coatings to prolong its lifespan 3.

Benefits

Utilizing the Cummins Fuel Supply Tube offers advantages such as improved fuel efficiency, enhanced reliability, and increased longevity. These benefits contribute to overall truck performance and can lead to reduced operational costs over time 4.

Installation and Compatibility

Proper installation of the Fuel Supply Tube is important for optimal performance and safety. It is compatible with various Cummins engines and may fit other truck models, though verifying compatibility is important for seamless integration 1.

Maintenance and Troubleshooting

Regular maintenance of the Fuel Supply Tube is recommended to ensure its longevity and performance. This includes periodic inspections for wear or damage and cleaning to remove contaminants. Addressing common issues such as leaks or blockages through routine checks and timely replacements helps maintain the efficiency of the fuel system 2.

Safety Considerations

Adhering to safety protocols when handling and installing the Fuel Supply Tube is important. Following manufacturer guidelines prevents fuel leaks and ensures safe operation, contributing to a secure fuel system 3.

Environmental Impact

The efficient design of the Fuel Supply Tube contributes to reduced fuel consumption and lower emissions. By ensuring consistent and efficient fuel delivery, it supports environmentally friendly operations in fleet management 4.

Cummins Overview

Cummins Inc. is known for its innovation and quality in the automotive industry, particularly in diesel engines and related technologies. Their commitment to advancing engine technology is evident in their product offerings, including the Fuel Supply Tube 3087766 1.

Integration with Engine Systems

N14 Mechanical

In the N14 Mechanical engine, the Fuel Supply Tube connects the fuel tank to the fuel injection pump, ensuring a consistent fuel supply for maintaining engine power output and efficiency 1.

NH/NT 855

In the NH/NT 855 engines, this part facilitates the transfer of fuel from the tank to the injection pump, ensuring smooth and efficient engine operation. It is designed to withstand heavy-duty applications, providing durability and reliability 1.

Role in Fuel Plumbing

The Fuel Supply Tube is a key element in the fuel plumbing system, connecting to the fuel tank at one end and to the fuel supply check valve at the other. This connection is vital for maintaining the integrity of the fuel line, preventing leaks, and ensuring fuel is delivered under the correct pressure 2.

Connection to Fuel Supply Check Valve Mounting

At the fuel supply check valve, the Fuel Supply Tube plays a role in the fuel supply check valve mounting. The check valve prevents fuel from flowing back into the tank, which could cause issues with fuel pressure and engine performance. The secure mounting of the Fuel Supply Tube to this valve is essential for the valve’s operation and the overall efficiency of the fuel system 3.

Role in Fuel Supply Plumbing

In the context of fuel supply plumbing, the Fuel Supply Tube is responsible for the direct transfer of fuel. It must be correctly routed to avoid interference with other engine components and to minimize the risk of damage or kinking, which could impede fuel flow 4.

Interaction with Fuel Tubing and Fuel Lines

The Fuel Supply Tube often interfaces with other fuel tubing and fuel lines. These connections must be tight and secure to prevent fuel leaks, which are not only a performance issue but also a safety concern. The tube must be compatible with the materials of the other fuel lines to ensure a seamless and durable connection 2.

Mounting the Fuel Supply Tube

The process of mounting the fuel supply tube involves securing it in place with clamps or brackets. This is done to protect the tube from physical damage and to maintain the correct alignment within the engine bay. Proper mounting is also important for thermal management, as it helps to prevent the tube from coming into contact with hot engine components 3.

Fuel Delivery and Engine Performance

Ultimately, the Fuel Supply Tube’s role in delivering fuel to the engine cannot be overstated. It must be able to withstand the pressures and temperatures of the fuel system while providing a consistent flow of fuel to meet the engine’s demands. This is particularly important under varying load conditions and during different phases of engine operation 4.

Conclusion

The Fuel Supply Tube 3087766 is a fundamental component that ensures the smooth operation of the fuel delivery system. Its proper installation and maintenance are key to the engine’s reliability and performance.

-

Forbes Aird, Bosch Fuel Injection Systems, HP Books, 2001.

↩ ↩ ↩ ↩ ↩ -

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ ↩ ↩ ↩ -

Hermann Hiereth, Peter Prenninger and Klaus W Drexl, Charging the Internal Combustion Engine, Springer, 2010.

↩ ↩ ↩ ↩ -

A. J. Wharton, Diesel Engines, Butterworth-Heinemann Ltd, 1991.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.