This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3352625 Fuel Supply Tube is a critical component in the fuel systems of heavy-duty trucks. It ensures the efficient transfer of fuel from the tank to the engine, maintaining a consistent supply under varying operational conditions. This part is essential for the engine’s efficiency and performance, providing a reliable fuel delivery system 1.

Purpose and Function

The Cummins 3352625 Fuel Supply Tube facilitates the transfer of fuel from the tank to the engine. It ensures a consistent pressure and flow rate, which is vital for the engine’s combustion process. This consistent delivery helps maintain engine performance and efficiency across different load and speed conditions 2.

Key Features

This Cummins part is designed with several features that enhance its performance and durability. It is constructed from high-quality materials resistant to corrosion and wear, ensuring longevity in demanding environments. The tube’s design allows for efficient fuel transfer, minimizing the risk of fuel starvation or leaks. Additionally, it is engineered to withstand the pressures and temperatures typical in heavy-duty truck fuel systems 3.

Benefits

Using the Cummins 3352625 Fuel Supply Tube offers several advantages. It contributes to improved fuel efficiency by ensuring a consistent and reliable fuel supply to the engine. The tube’s robust construction and materials enhance the reliability of the fuel system, reducing the likelihood of failures. Furthermore, it is designed to be compatible with Cummins engines, ensuring seamless integration and optimal performance.

Installation and Compatibility

Proper installation of the Cummins 3352625 Fuel Supply Tube is crucial for its effective operation. The installation process requires specific tools and should follow manufacturer guidelines to ensure a secure fit. Compatibility with various Cummins engine models is a key consideration, ensuring that the tube fits and functions correctly within the intended engine systems.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3352625 Fuel Supply Tube is important for ensuring its longevity and optimal performance. This includes checking for signs of wear or damage and ensuring all connections are secure. Common issues may include fuel leaks or inconsistent fuel delivery, which can often be addressed by inspecting and tightening connections or replacing worn components.

Safety Considerations

When working with the Cummins 3352625 Fuel Supply Tube, it is important to follow safety practices. This includes ensuring proper ventilation when working with fuel systems to avoid the accumulation of flammable vapors. Additionally, handling the tube and associated components with care can prevent damage and ensure safe operation.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications. The company’s extensive product range and focus on technological advancement underscore its position as a leader in the diesel engine and components industry.

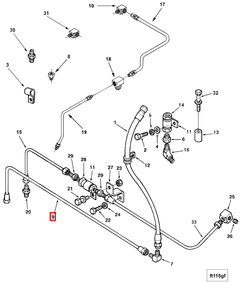

Integration with Fuel System Components

-

Fuel Tank: The Fuel Supply Tube connects directly to the fuel tank, where it draws fuel. This connection is typically secured with a fitting that prevents leaks and ensures a tight seal.

-

Fuel Pump: In systems equipped with an in-tank fuel pump, the Fuel Supply Tube is routed from the pump outlet to the engine bay. The fuel pump pressurizes the fuel, which is then transported through the tube.

-

Fuel Filter: Often, the Fuel Supply Tube is connected to a fuel filter, which removes impurities from the fuel before it reaches the engine. This ensures that only clean fuel is delivered, protecting the injectors and other sensitive components.

-

Fuel Rail: In fuel-injected engines, the Fuel Supply Tube feeds into the fuel rail, which distributes fuel to each injector. The tube ensures that the rail maintains the necessary pressure for optimal injector performance.

-

Carburetor: In carbureted engines, the Fuel Supply Tube delivers fuel to the carburetor, where it is mixed with air before entering the combustion chamber. This tube must be properly routed to avoid kinks or restrictions that could affect fuel flow.

-

Fuel Return Line: Some systems include a fuel return line that sends excess fuel back to the tank. The Fuel Supply Tube works in conjunction with this line to maintain the correct fuel pressure within the system.

Ensuring System Integrity

The Fuel Supply Tube must be correctly installed to prevent fuel leaks, which can pose safety hazards. It should be routed away from heat sources and moving parts to avoid damage. Regular inspections for wear, cracks, or leaks are essential to maintain the integrity of the fuel system.

Conclusion

The Cummins 3352625 Fuel Supply Tube plays a significant role in the efficient operation of engine systems by ensuring a steady and clean fuel supply to the combustion process. Its robust design, compatibility with Cummins engines, and integration with various fuel system components make it a vital part of the fuel delivery system.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩ -

Arthur J Caines, Roger F Haycock and John E Hillier, Automotive Lubricants Reference Book, SAE International, 2004.

↩ -

QSG12 CM2880 G112, Service Manual (4388731).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.