This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

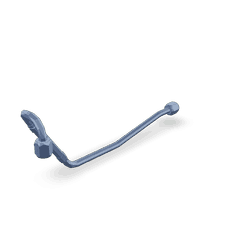

The Cummins 4297025 Fuel Supply Tube is a critical component in the fuel systems of heavy-duty trucks. It ensures a consistent fuel supply from the tank to the engine, which is essential for maintaining the efficiency and performance of the vehicle’s fuel system.

Purpose and Function

This Cummins part facilitates the delivery of fuel from the tank to the engine, maintaining consistent fuel pressure and flow. This ensures that the engine receives the necessary fuel quantity at the correct pressure, which is vital for optimal combustion and engine performance. The tube’s design allows it to handle the demands of high-pressure fuel systems commonly found in heavy-duty applications 1.

Design and Construction

The Fuel Supply Tube is constructed from materials that offer durability and resistance to the corrosive effects of diesel fuel. It may include protective coatings or reinforcements to enhance its longevity and performance under various operating conditions. These design features help to prevent leaks and ensure reliable fuel delivery 2.

Integration within the Fuel System

The Fuel Supply Tube is a key component within the overall fuel system. It connects to the fuel tank at one end and to the fuel filter or engine at the other, forming a critical link in the fuel delivery process. Its design allows for secure connections that resist disconnection and fuel leaks, ensuring a seamless integration with other fuel system components.

Benefits of Using Cummins 4297025 Fuel Supply Tube

Utilizing the Cummins 4297025 Fuel Supply Tube offers several advantages. These include improved fuel efficiency due to consistent fuel delivery, enhanced durability that withstands the rigors of heavy-duty use, and reliable performance under a range of operating conditions. The tube’s design contributes to the overall efficiency and reliability of the fuel system 3.

Common Issues and Troubleshooting

Typical problems that may arise with the Fuel Supply Tube include leaks or blockages. These issues can often be identified through regular inspections and maintenance checks. Troubleshooting steps may involve checking connections for tightness, inspecting the tube for signs of wear or damage, and ensuring that there are no obstructions in the fuel line.

Maintenance and Care

Regular inspection and maintenance of the Fuel Supply Tube are important for ensuring its longevity and optimal performance. This includes checking for signs of wear, ensuring connections are secure, and cleaning the tube as necessary. Replacement schedules should be followed to prevent failures and ensure consistent fuel delivery.

Safety Considerations

When handling and maintaining the Fuel Supply Tube, it is important to follow safety practices to avoid fuel spills and ensure proper system pressure. This includes working in a well-ventilated area, using appropriate personal protective equipment, and following manufacturer guidelines for maintenance and repair.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and components. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications.

Conclusion

The Cummins 4297025 Fuel Supply Tube is a vital component in the fuel systems of heavy-duty trucks. Its role in ensuring a consistent and reliable fuel supply to the engine is crucial for maintaining the vehicle’s performance and efficiency. Regular maintenance and adherence to safety practices are essential for the longevity and optimal performance of this part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.