This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4894224 Double End Plain Stud, a component manufactured by Cummins, plays a significant role in the automotive and heavy-duty truck industry. This stud is crucial for maintaining the integrity and functionality of various mechanical systems in heavy-duty trucks. Understanding its purpose, features, and proper usage is essential for ensuring the performance and reliability of these vehicles.

Basic Concepts of Double End Plain Studs

A Double End Plain Stud is a fastener with threaded sections on both ends, designed to be screwed into two separate components. This design provides a secure and stable connection that can withstand significant stress and vibration. In heavy-duty trucks, these studs are used in engine assemblies, transmission systems, and other critical components where durability and strength are essential 1.

Purpose of the 4894224 Double End Plain Stud in Truck Operations

This Cummins part secures components within the truck’s mechanical systems, ensuring that parts remain aligned and connected under demanding conditions. Its applications include engine block assemblies, where it maintains the structural integrity of the engine by securely fastening parts together 2.

Key Features

The 4894224 Double End Plain Stud is made from high-strength materials, ensuring it can withstand the rigors of heavy-duty truck operations. Its design specifications, including thread size and length, are tailored to meet specific application requirements, providing a secure and reliable connection. Surface treatments for corrosion resistance further enhance its performance and longevity 3.

Benefits

Utilizing this stud offers several advantages. Its robust construction and design contribute to improved reliability, reducing the likelihood of component failure under stress. The ease of installation, facilitated by its double-ended design, allows for efficient assembly and maintenance procedures. Over time, the durability and reliability of this stud can lead to potential cost savings by minimizing the need for frequent replacements or repairs.

Installation Process

Installing the 4894224 Double End Plain Stud involves cleaning the mating surfaces, aligning the stud with the designated holes, and screwing it into place using appropriate tools. It is important to apply the correct torque specifications to avoid over-tightening, which could damage the stud or the components it is securing.

Troubleshooting and Maintenance

Common issues with Double End Plain Studs include loosening over time due to vibration or thermal expansion and contraction. Regular inspections can help identify problems early, allowing for timely adjustments or replacements. Maintenance practices, such as applying thread lockers and ensuring proper torque during installation, can enhance the longevity and optimal performance of these studs.

Safety Considerations

When handling, installing, or maintaining the 4894224 Double End Plain Stud, it is important to observe safety guidelines to ensure personal safety and component integrity. This includes using appropriate personal protective equipment (PPE), such as gloves and safety glasses, and ensuring that all tools and equipment are in good working condition. Additionally, following the manufacturer’s guidelines for installation and torque specifications is crucial to prevent damage to the stud or the components it secures.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. The company’s extensive product range and commitment to excellence make it a trusted name among professionals and enthusiasts alike.

Double End Plain Stud (Part 4894224) in Cummins Engines

The Double End Plain Stud, identified by part number 4894224, is a critical component in various Cummins engines, including the ISBE CM800 series. This part is designed to provide robust and reliable fastening in engine assemblies, ensuring that components are securely held together under operational stresses.

Application in Cummins Engines

ISBE CM800 Series

In the ISBE CM800 engines, the Double End Plain Stud is utilized in several critical areas. Its design allows it to be inserted into pre-drilled holes, providing a strong and stable connection between engine parts. This stud is particularly important in maintaining the integrity of engine assemblies, where precise alignment and secure fastening are paramount.

Other Cummins Engines

Beyond the ISBE CM800 series, the Double End Plain Stud is also a key component in various other Cummins engine models. Its versatility and strength make it suitable for use in different engine configurations, ensuring that the engine components remain securely fastened during operation. This part’s ability to withstand high loads and stresses is essential for the overall performance and longevity of the engine.

Importance in Engine Assembly

The Double End Plain Stud is integral to the assembly and maintenance of Cummins engines. Its design allows for easy installation and removal, facilitating efficient maintenance procedures. The stud’s ability to provide a tight and secure fit is crucial for preventing engine vibrations and ensuring that components remain in their intended positions under varying operational conditions.

Compatibility and Usage

The Double End Plain Stud is engineered to meet the stringent requirements of Cummins engines. Its compatibility with various engine models ensures that it can be used across different engine types, providing a consistent and reliable fastening solution. This part’s widespread use in Cummins engines underscores its importance in maintaining engine performance and reliability.

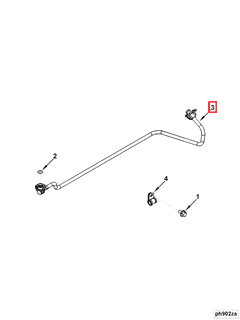

Part 4894224 Double End Plain Stud Component Usage

The 4894224 Double End Plain Stud is instrumental in ensuring the secure and reliable connection of various components within engine systems. Its application is particularly significant in the context of the Engine Control Module (ECM) Plumbing, Fuel Supply Tube, and general Plumbing systems associated with the ECM.

In the ECM Plumbing system, the Double End Plain Stud is used to fasten critical connections that ensure the integrity of the fluid pathways. This includes securing fittings and adapters that are essential for the proper operation of the ECM. The stud’s design allows for a robust connection that can withstand the pressures and vibrations inherent in engine operation.

When it comes to the Fuel Supply Tube, the Double End Plain Stud plays a role in maintaining the secure attachment of the tube to the fuel system. This is vital for ensuring a consistent and reliable fuel delivery to the engine, which is fundamental for performance and efficiency.

In the broader context of Plumbing associated with the ECM, the Double End Plain Stud is employed to connect various sensors, actuators, and other components to the ECM. This ensures that all electrical and fluid connections are maintained under the dynamic conditions of engine operation.

Overall, the 4894224 Double End Plain Stud is a key component in the assembly and maintenance of engine systems, providing the necessary connections that contribute to the overall reliability and performance of the engine.

Conclusion

The 4894224 Double End Plain Stud is a vital component in the maintenance and operation of heavy-duty trucks and Cummins engines. Its robust design, ease of installation, and reliable performance make it an essential part for ensuring the integrity and functionality of various mechanical systems. Proper installation, maintenance, and adherence to safety guidelines are crucial for maximizing the benefits of this stud and ensuring the longevity and reliability of the engine systems it supports.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.