Introduction

The Cummins 3415661 Fuel Transfer Pump is a component designed for use in heavy-duty trucks. It facilitates the movement of fuel from the tank to the engine, ensuring a consistent supply of fuel under various operating conditions. This pump is integral to the efficient operation of the truck’s fuel system, contributing to overall performance and reliability.

Basic Concepts of Fuel Transfer Pumps

A fuel transfer pump is a device that moves fuel from the storage tank to the engine’s fuel system. It operates by creating a pressure differential that allows fuel to flow through the system. In the context of a truck, the fuel transfer pump ensures that fuel is delivered at the correct pressure and volume to meet the engine’s demands, particularly under high-load or high-altitude conditions 1.

Purpose of the Cummins 3415661 Fuel Transfer Pump

The Cummins 3415661 Fuel Transfer Pump plays a specific role in the truck’s fuel delivery system. It is responsible for transferring fuel from the tank to the engine, maintaining the necessary pressure to ensure efficient fuel delivery. This pump is designed to handle the demands of heavy-duty applications, providing a reliable fuel supply that supports the engine’s performance.

Key Features

The Cummins 3415661 Fuel Transfer Pump is characterized by several key features that enhance its performance. These include a robust design that can withstand the rigors of heavy-duty use, the use of high-quality materials to ensure durability, and unique characteristics such as precise engineering to maintain consistent fuel delivery. These features contribute to the pump’s reliability and efficiency in demanding applications.

Benefits

The Cummins 3415661 Fuel Transfer Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered at the optimal pressure and volume. The pump’s reliable operation enhances the overall performance of the truck, while its durable construction supports long-term use without frequent replacements 2.

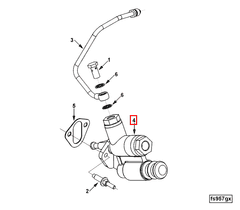

Installation Process

Installing the Cummins 3415661 Fuel Transfer Pump requires careful attention to detail. The process involves ensuring that the fuel system is clean and free of contaminants, securing the pump in place, and connecting it to the fuel lines. Tools such as wrenches and sealant may be required. Following the manufacturer’s instructions ensures proper installation and optimal performance.

Common Issues and Troubleshooting

Fuel transfer pumps may encounter issues such as fuel delivery problems or pump failure. Diagnosing these issues involves checking for fuel leaks, verifying pump operation, and inspecting fuel lines for blockages. Potential solutions include cleaning or replacing fuel filters, repairing or replacing damaged fuel lines, and, if necessary, replacing the pump 3.

Maintenance Tips

Regular maintenance of the Cummins 3415661 Fuel Transfer Pump is important for ensuring its longevity and optimal performance. This includes periodic inspection of the pump and fuel lines for signs of wear or damage, cleaning or replacing fuel filters as needed, and ensuring that the fuel system remains free of contaminants. Adhering to a maintenance schedule helps prevent issues and extends the life of the pump.

Safety Considerations

When working with the Cummins 3415661 Fuel Transfer Pump, it is important to observe safety guidelines to prevent accidents. This includes ensuring that the fuel system is depressurized before beginning work, using appropriate personal protective equipment, and following all manufacturer safety recommendations. These precautions help ensure safe operation and maintenance of the pump.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry, particularly for its diesel engines and components. The company’s commitment to excellence is reflected in its products, including the Cummins 3415661 Fuel Transfer Pump 4.

Compatibility of Cummins Fuel Transfer Pump 3415661

The Cummins Fuel Transfer Pump part number 3415661 is designed to be compatible with a range of engine models. This part is essential for ensuring the efficient transfer of fuel within the engine system, contributing to overall performance and reliability.

L8.9 and L121 Engines

The Cummins Fuel Transfer Pump 3415661 is specifically engineered to fit seamlessly with the L8.9 and L121 engine models. These engines benefit from the precise fuel delivery that this transfer pump provides, ensuring optimal combustion and power output.

L9.5 and L117 Engines

Similarly, the L9.5 and L117 engines are also compatible with the Cummins Fuel Transfer Pump part number 3415661. This compatibility ensures that these engines receive the necessary fuel supply, maintaining their operational efficiency and performance standards.

By ensuring compatibility with these engine models, the Cummins Fuel Transfer Pump 3415661 provides a reliable solution for maintaining the integrity of the fuel system across various engine types.

Role of Part 3415661 Fuel Transfer Pump in Engine Systems

The Fuel Transfer Pump, identified by part number 3415661, is an integral component within the fuel system of various engine setups. Its primary function is to move fuel from the main tank to the engine’s fuel injection system, ensuring a consistent and reliable supply of fuel under all operating conditions.

Integration with Fuel System Components

-

Fuel Tank: The process begins at the fuel tank, where the Fuel Transfer Pump draws fuel. This pump is designed to handle the specific viscosity and pressure requirements of the fuel, ensuring efficient transfer without cavitation or fuel starvation.

-

Fuel Lines: Once the fuel is drawn from the tank, it travels through the fuel lines. The Fuel Transfer Pump maintains a steady pressure within these lines, which is essential for preventing air pockets and ensuring a smooth flow of fuel to the engine.

-

Fuel Filter: Before reaching the engine, the fuel passes through a fuel filter. The consistent pressure provided by the Fuel Transfer Pump ensures that the filter can effectively remove contaminants without restricting fuel flow.

-

Fuel Injection System: The Fuel Transfer Pump delivers fuel to the fuel injection system at the precise pressure required for optimal combustion. This ensures that the fuel injectors receive a steady supply of clean, pressurized fuel, which is vital for engine performance and efficiency.

-

Return Lines: In systems where excess fuel is returned to the tank, the Fuel Transfer Pump helps maintain the correct pressure differential, facilitating the return flow and preventing fuel overflow.

Operational Synergy

The Fuel Transfer Pump works in concert with other engine components to maintain fuel system integrity. Its reliable operation is essential for:

- Engine Start-Up: Providing the initial fuel pressure needed for a smooth start.

- Idle Stability: Ensuring a consistent fuel supply at low engine speeds.

- High-Performance Demands: Delivering the necessary fuel volume and pressure during acceleration and high-load conditions.

Conclusion

In summary, the Fuel Transfer Pump (part 3415661) plays a significant role in the fuel delivery process, interacting with various components to ensure the engine receives a consistent and clean fuel supply under all operating conditions.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Ling, F. F. (2011). The Automotive Body. Springer Science.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.