This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 180795 Lubricating Pump Gasket is a component designed to facilitate the efficient operation of commercial trucks. Cummins, a well-established name in the automotive industry, is renowned for its commitment to quality and innovation. This gasket plays a significant role in the lubrication system of truck engines, contributing to their performance and longevity.

Basic Concepts of Lubricating Pump Gaskets

A lubricating pump gasket is a sealing component used within the lubrication system of an engine. Its primary function is to ensure a secure seal around the lubricating pump, preventing oil leaks and maintaining consistent oil pressure. This consistent pressure is vital for the proper lubrication of engine components, which in turn supports the engine’s overall performance and extends its operational life 1.

Purpose of the 180795 Lubricating Pump Gasket

The 180795 Lubricating Pump Gasket is specifically designed to seal the lubricating pump in truck engines. By creating a tight seal, it helps maintain the necessary oil pressure within the lubrication system. This ensures that engine components receive adequate lubrication, reducing friction and wear, and supporting the engine’s efficient operation 2.

Key Features

The 180795 Lubricating Pump Gasket is crafted from high-quality materials, ensuring durability and reliability. Its design specifications are tailored to fit precisely within the lubrication system, providing an effective seal. Unique attributes of this gasket include its resistance to oil and heat, which enhances its performance under the demanding conditions of commercial truck engines 3.

Benefits

Utilizing the 180795 Lubricating Pump Gasket offers several advantages. It contributes to improved engine efficiency by ensuring optimal lubrication. Reduced wear and tear on engine components lead to longer engine life. Additionally, the gasket enhances the reliability of the lubrication system, minimizing the risk of oil leaks and maintaining consistent oil pressure.

Installation Process

Installing the 180795 Lubricating Pump Gasket requires careful attention to detail. Preparatory steps include cleaning the mating surfaces to ensure a proper seal. The installation process involves positioning the gasket correctly around the lubricating pump and securing it in place. Using the appropriate tools and following best practices ensures a secure fit, which is crucial for the gasket’s effectiveness.

Troubleshooting Common Issues

Common issues with lubricating pump gaskets include leaks or failure, which can lead to oil loss and decreased lubrication efficiency. Troubleshooting these problems involves inspecting the gasket for signs of wear or damage, checking the fit around the lubricating pump, and ensuring that all connections are secure. Addressing these issues promptly helps maintain the integrity of the lubrication system.

Maintenance Tips

Routine maintenance practices can prolong the lifespan of the 180795 Lubricating Pump Gasket. Regular inspections for signs of wear or damage are recommended. Cleaning the gasket and its surrounding areas can prevent contamination that might affect its performance. Knowing when to consider replacement, based on the condition of the gasket and the manufacturer’s guidelines, ensures continued reliable operation of the lubrication system.

Compatibility and Application

The 180795 Lubricating Pump Gasket is designed for use with specific Cummins engines, ensuring a proper fit and function. Its application is tailored to meet the demands of these engines, providing effective sealing and contributing to the overall performance of the lubrication system.

Cummins: A Brief Overview

Cummins Inc. is a leader in the commercial truck industry, known for its extensive product range and commitment to quality and innovation. With a history of delivering reliable and efficient engine solutions, Cummins has established a strong reputation among commercial truck operators and manufacturers alike. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a trusted provider in the industry.

Cummins Lubricating Pump Gasket 180795 Compatibility

The Cummins Lubricating Pump Gasket 180795 is a critical component designed to ensure the integrity and efficiency of the lubrication system in various engine models. This gasket is engineered to fit seamlessly with specific Cummins engines, providing a reliable seal that prevents oil leaks and maintains optimal engine performance.

Engine Compatibility

The 180795 gasket is compatible with the following Cummins engine models:

- V903

This gasket is meticulously designed to fit the unique specifications of the V903 engine, ensuring a perfect seal and preventing any potential oil leakage. Its precision engineering guarantees that it will function effectively within the engine’s lubrication system, contributing to the overall longevity and reliability of the engine.

By using the Cummins Lubricating Pump Gasket 180795, engine operators can be confident that their V903 engine will maintain its operational integrity, free from the risks associated with oil leaks and lubrication system failures.

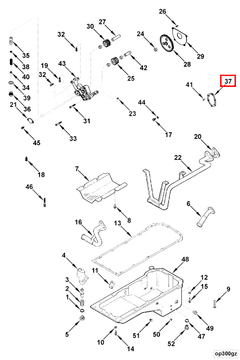

Role of Part 180795 Lubricating Pump Gasket in Engine Systems

The part 180795 Lubricating Pump Gasket is an essential component in ensuring the integrity and efficiency of various engine systems. This gasket is specifically designed to fit within the lubricating assembly pump, where it plays a significant role in maintaining the seal between the lubricating oil pump and the lubricating oil pump body.

In the context of an engine gasket set or an overhaul gasket set, the 180795 gasket ensures that there are no leaks between the pump and the pump body, which is vital for the consistent delivery of lubricating oil throughout the engine.

When integrated into a PDC (Powertrain Control Module) system, this gasket helps in maintaining the precise oil pressure required for optimal engine performance.

In the lower engine gasket set, the 180795 gasket works in conjunction with other gaskets to create a reliable seal, preventing oil from escaping and contaminating other engine components.

Its placement between the lubricating oil pump and the oil pan is particularly important, as it ensures that the oil pan remains free from excess oil, which could lead to sludge formation and reduced engine efficiency.

Finally, in the context of the lubricating oil pump mounting, the 180795 gasket ensures that the pump is securely attached to the engine block, further contributing to the overall stability and performance of the lubricating system.

Conclusion

The Cummins 180795 Lubricating Pump Gasket is a vital component in the lubrication system of commercial truck engines. Its role in maintaining consistent oil pressure, preventing leaks, and ensuring optimal lubrication contributes significantly to engine performance and longevity. Proper installation, maintenance, and timely replacement of this gasket are essential for the reliable operation of the engine’s lubrication system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.