196416

Scavenge Pump Gasket

Cummins®

AVAILABLE

8 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Scavenge Pump Gasket, identified by part number 196416, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly in heavy-duty truck engines. This Cummins part plays a significant role in ensuring the efficient operation of the engine by maintaining seal integrity and preventing oil leaks within the scavenge pump system.

Function and Operation

The Scavenge Pump Gasket operates by creating a seal between the scavenge pump and the engine block. This seal is vital for maintaining the integrity of the oil system, ensuring that oil is effectively circulated and returned to the sump without leakage. The gasket’s role in preventing oil leaks contributes to the overall efficiency and reliability of the engine system 1.

Purpose of the Scavenge Pump Gasket

In the context of a truck’s operation, the Scavenge Pump Gasket serves a specific function within the scavenge pump system. It ensures that the scavenge pump can effectively draw oil from the sump and return it to the engine’s lubrication system. This process is crucial for maintaining proper lubrication levels, which in turn supports engine performance and longevity 2.

Key Features

The Scavenge Pump Gasket is designed with several key features that enhance its performance. These include a material composition that is resistant to oil and heat, ensuring durability under the demanding conditions of a heavy-duty truck engine. Its design specifications are tailored to fit precisely within the engine system, providing a reliable seal. Additionally, any unique attributes, such as reinforced edges or specialized coatings, further contribute to its effectiveness.

Benefits

Utilizing the Scavenge Pump Gasket offers several benefits. It contributes to improved engine efficiency by ensuring that the oil system operates without leaks, thereby maintaining optimal lubrication. This can lead to reduced maintenance costs, as the need for frequent oil changes or repairs due to leaks is minimized. Furthermore, the gasket enhances the reliability of the engine system, supporting consistent performance over time 3.

Installation Process

Proper installation of the Scavenge Pump Gasket is crucial for its effectiveness. The process involves cleaning the mating surfaces to ensure a proper seal, positioning the gasket correctly, and securing it in place without damaging the material. Best practices include using the appropriate torque specifications for any fasteners involved and avoiding over-tightening, which could compromise the gasket’s integrity.

Common Issues and Troubleshooting

Common issues with the Scavenge Pump Gasket may include leaks due to improper installation, material degradation over time, or damage from extreme operating conditions. Troubleshooting these issues involves inspecting the gasket for signs of wear or damage, ensuring it is correctly installed, and replacing it if necessary. Regular maintenance checks can help identify potential problems before they lead to significant issues.

Maintenance Tips

To prolong the lifespan of the Scavenge Pump Gasket, regular inspection intervals are recommended. This includes checking for signs of wear, ensuring the gasket remains properly seated, and verifying that there are no oil leaks. Recommended maintenance procedures may also involve cleaning the mating surfaces during oil changes to prevent contamination that could affect the gasket’s performance.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, with a history of producing high-quality engines and components for heavy-duty applications. Their product range includes a variety of engine parts and systems designed to meet the demanding requirements of commercial and industrial use. Cummins’ reputation for quality and reliability makes their components, including the Scavenge Pump Gasket, a preferred choice for maintaining and upgrading heavy-duty truck engines.

Role of Part 196416 Scavenge Pump Gasket in Engine Systems

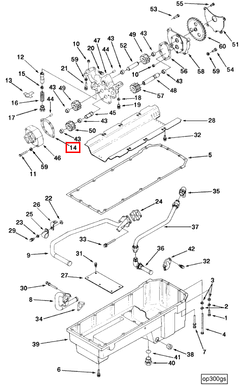

The Scavenge Pump Gasket, identified as part 196416, is an essential component in the assembly and operation of various engine systems. Its primary function is to ensure a secure and leak-free seal between the scavenge pump and the cylinder block. This gasket is integral in maintaining the integrity of the lubricating oil system, which is vital for the engine’s performance and longevity.

When installing or overhauling an engine, the Scavenge Pump Gasket works in conjunction with the Lower Engine Gasket Set and the Overhaul Gasket Set. These gaskets collectively prevent oil leaks and maintain proper oil pressure throughout the engine. The Scavenge Pump Gasket specifically addresses the interface between the scavenge pump and the cylinder block, ensuring that oil is efficiently drawn from the sump and delivered to the Lubricating Oil Pump.

The Lubricating Oil Pump relies on a consistent supply of oil to distribute lubrication to critical engine components. The Scavenge Pump Gasket plays a role in this process by ensuring that the oil picked up from the pan is free from contaminants and leaks. This gasket helps maintain the efficiency of the oil pump and the overall lubrication system.

Conclusion

In summary, the Scavenge Pump Gasket (part 196416) is a key component in the engine’s oil management system. It ensures a reliable seal, supports efficient oil circulation, and contributes to the engine’s durability and performance.

-

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Quigley, J. M. (2023). SAE International’s Dictionary of Testing, Verification and Validation. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.