This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

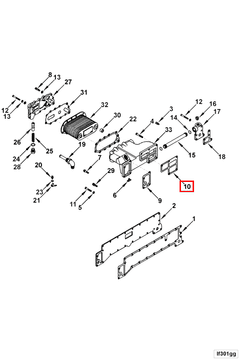

The Lubricating Oil Cooler Housing Gasket, identified by Part #3013779, is a component manufactured by Cummins. This gasket is integral to the maintenance of heavy-duty trucks, ensuring the efficient operation of the lubricating oil cooling system. Cummins, a well-established name in the commercial truck industry, produces this gasket to meet the demanding requirements of truck engines 1.

Function and Operation

The Lubricating Oil Cooler Housing Gasket operates within the lubricating oil cooling system by providing a seal between the oil cooler housing and the engine block or oil cooler. Its role is to maintain the integrity of the cooling system, ensuring that oil is effectively cooled as it circulates. By keeping the oil at an optimal temperature, the gasket contributes to the overall efficiency and reliability of the engine 2.

Key Features

The design and material characteristics of the Lubricating Oil Cooler Housing Gasket are tailored for durability and effectiveness in sealing applications. Typically made from high-quality materials resistant to oil, heat, and pressure, this gasket is engineered to withstand the harsh conditions within an engine compartment. Its precise fit and robust construction ensure a reliable seal, preventing oil leaks and maintaining system pressure 3.

Benefits

The advantages provided by the Lubricating Oil Cooler Housing Gasket include improved engine performance, extended component lifespan, and enhanced overall reliability of the truck’s lubrication system. By ensuring that the oil remains at an optimal temperature, the gasket helps to reduce engine wear, improve fuel efficiency, and prolong the life of engine components. Additionally, a properly sealed cooling system contributes to the stability and reliability of the truck’s operation 4.

Installation and Maintenance

Proper installation of the Lubricating Oil Cooler Housing Gasket is crucial for its effectiveness. Guidelines for installation include adhering to specified torque settings to ensure a secure fit without over-tightening, which could damage the gasket or surrounding components. Regular maintenance checks are recommended to ensure the gasket remains in good condition, with replacement advised if signs of wear or damage are detected.

Troubleshooting Common Issues

Typical problems associated with Lubricating Oil Cooler Housing Gaskets may include leaks or failures, often due to wear, improper installation, or exposure to extreme conditions. Diagnostic methods involve visual inspection for signs of oil leakage around the gasket area and pressure testing the cooling system. Recommended solutions may include re-torquing the gasket, applying a sealing compound, or replacing the gasket if necessary.

Cummins Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its comprehensive range of diesel engines, related technologies, and services. With a history spanning several decades, Cummins has established a reputation for quality, innovation, and reliability. The company’s product portfolio includes engines, filtration systems, emissions solutions, and aftermarket parts, all designed to meet the rigorous demands of commercial transportation.

Cummins Engine Part 3013779: Lubricating Oil Cooler Housing Gasket

The Cummins part 3013779, a Lubricating Oil Cooler Housing Gasket, is a crucial component designed to ensure the integrity and efficiency of the oil cooling system in various Cummins engines. This gasket is engineered to provide a secure seal between the oil cooler housing and the engine block, preventing oil leaks and maintaining the optimal operating temperature of the engine oil.

Application in Cummins Engines

The part 3013779 is specifically tailored to fit into the following Cummins engine models:

- V903 Series: This gasket is integral to the V903 engines, ensuring that the oil cooler housing is properly sealed. The V903 engines are known for their robust design and are often used in heavy-duty applications, where maintaining the integrity of the oil cooling system is critical.

Importance of the Gasket

The proper installation of the 3013779 gasket is essential for several reasons:

- Prevents Oil Leaks: By creating a tight seal, the gasket prevents oil from leaking out of the cooler housing, which could lead to engine damage and reduced performance.

- Maintains Oil Temperature: A well-sealed oil cooler housing ensures that the engine oil remains at the correct temperature, which is vital for engine longevity and efficiency.

- Reduces Maintenance Costs: By preventing leaks and ensuring the oil cooler operates correctly, the gasket helps reduce the need for frequent maintenance and repairs.

Installation Considerations

When installing the 3013779 gasket, it is important to follow the manufacturer’s guidelines to ensure a proper fit and seal. This includes:

- Cleaning Surfaces: Ensuring that the mating surfaces are clean and free of debris before installation.

- Correct Alignment: Properly aligning the gasket to avoid misalignment, which can lead to leaks.

- Torque Specifications: Adhering to the specified torque settings when securing the oil cooler housing to prevent over-tightening or under-tightening.

By understanding the role and importance of the Cummins part 3013779 in the V903 engines, technicians and engine operators can ensure that their engines run smoothly and efficiently.

Role of Part 3013779 Lubricating Oil Cooler Housing Gasket in Engine Systems

In engine systems, the lubricating oil cooler housing gasket (part 3013779) serves as a vital component that ensures the integrity and efficiency of the lubricating oil system. This gasket is specifically designed to seal the lubricating oil cooler housing, preventing any leaks that could compromise the system’s performance.

When integrated into the engine, the lubricating oil cooler housing gasket works in conjunction with the lubricating oil filter to maintain clean oil circulation. The filter removes contaminants from the lubricating oil, ensuring that only clean oil passes through the system. The gasket, in turn, ensures that this clean oil remains within the designated pathways, preventing any external leakage.

The lower engine gasket set also plays a complementary role. These gaskets are positioned at the lower sections of the engine, sealing various components and compartments. The lubricating oil cooler housing gasket, by ensuring a tight seal around the oil cooler, supports the lower gasket set’s function by maintaining consistent oil pressure and flow.

Furthermore, the lubricating oil mounting cooler, which is responsible for dissipating heat from the lubricating oil, relies on the gasket to create a secure environment. Any gap or leak could result in inefficient heat exchange, potentially leading to overheating issues.

The oil cooler itself benefits from the gasket’s sealing properties. As the oil cooler works to regulate the temperature of the lubricating oil, the gasket ensures that the cooled oil remains within the system, optimizing the cooling process.

Lastly, during an engine overhaul, the overhaul gasket set, which includes various gaskets designed to seal different engine components, works in harmony with the lubricating oil cooler housing gasket. This ensures that all seals are intact, facilitating a smooth and efficient overhaul process.

Conclusion

In summary, the Lubricating Oil Cooler Housing Gasket (part 3013779) is an essential component that supports the functionality of several other engine components, ensuring optimal performance and efficiency of the lubricating oil system. Its proper installation and maintenance are crucial for the longevity and reliability of heavy-duty truck engines.

-

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Lejda, Kazimierz, and Pawel Wos. Internal Combustion Engines. InTech, 2012.

↩ -

Reif, Konrad, ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.