This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3423291 Flange Gasket, manufactured by Cummins, is a component designed for use in commercial trucks. It is integral to the sealing applications within truck engines, ensuring that connections between flanged components remain sealed under various operating conditions. Gaskets play a significant role in maintaining the integrity of engine systems by preventing leaks and ensuring efficient operation 1.

Basic Concepts of Flange Gaskets

Flange gaskets are sealing devices placed between flanged surfaces to create a seal. They operate by filling the space between the flanges, compensating for surface imperfections, and withstanding the pressure exerted by the bolted connection. These gaskets are typically made from materials such as rubber, graphite, metal, or composite materials, each offering unique properties like flexibility, thermal resistance, and chemical stability 2.

Purpose of the 3423291 Flange Gasket

The 3423291 Flange Gasket is specifically designed to seal flanged connections in truck engine components. It ensures that fluids and gases remain contained within the system, preventing leaks that could lead to engine inefficiency or failure. By providing a reliable seal, this gasket contributes to the overall performance and durability of the engine 3.

Key Features

The 3423291 Flange Gasket features a design tailored to the specific requirements of truck engines. It is composed of materials that offer high resistance to temperature and pressure, ensuring durability in demanding environments. Its unique attributes include precise dimensional tolerances and a robust construction that enhances sealing efficiency and longevity.

Benefits

Using the 3423291 Flange Gasket offers several advantages. It provides improved sealing efficiency, which is crucial for maintaining engine performance. The gasket’s resistance to high temperatures and pressures ensures it can withstand the rigors of truck engine operation. Additionally, its design contributes to longevity, reducing the need for frequent replacements and maintenance.

Installation Considerations

Proper installation of the 3423291 Flange Gasket is vital for its effectiveness. This involves preparing the flange surfaces to ensure they are clean and free from debris. Torque specifications should be followed to achieve the correct compression without over-tightening, which could damage the gasket. Ensuring proper alignment and compression is also critical for a reliable seal.

Troubleshooting Common Issues

Common issues with flange gaskets include leaks or failures, often due to improper installation, wear, or damage. Troubleshooting steps involve inspecting the gasket and flange surfaces for signs of wear or misalignment. If leaks are detected, it may be necessary to replace the gasket to restore the seal and prevent further engine issues.

Maintenance Tips

Regular maintenance of the 3423291 Flange Gasket involves periodic inspections for signs of wear or damage. Establishing inspection intervals based on the operating conditions can help identify issues before they lead to failure. Preventive measures, such as ensuring proper installation and operating within specified parameters, can extend the gasket’s service life.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of engine components and commitment to quality and innovation. With a history of providing reliable and efficient engine solutions, Cummins has established a reputation for excellence in the manufacturing of engine parts, including the 3423291 Flange Gasket.

Role of Part 3423291 Flange Gasket in Engine Systems

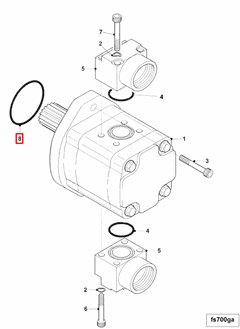

The 3423291 Flange Gasket is an essential component in ensuring the integrity and efficiency of various engine systems. It is strategically positioned between mating surfaces to provide a seal that prevents leaks and maintains system pressure. Here’s how it integrates with the provided components:

Accessory Drive Assembly Housing

In the accessory drive assembly housing, the flange gasket ensures a tight seal between the housing and the engine block. This prevents any fluid or gas leaks that could affect the performance of accessories driven by the engine, such as the alternator or air conditioning compressor.

Drive and Front Gear Train Accessory

When installed in the drive and front gear train accessory, the flange gasket maintains the seal between the gear housing and the engine. This is vital for keeping lubricants within the system, ensuring smooth operation and reducing wear on the gears.

Fuel Transfer Assembly Pump

For the fuel transfer assembly pump, the flange gasket seals the connection between the pump housing and the engine or fuel system components. This ensures that fuel is transferred efficiently without any leaks, which is essential for consistent engine performance.

Gear Assembly Housing

In the gear assembly housing, the flange gasket provides a secure seal between the housing and other engine components. This is important for maintaining the proper lubrication and operation of the gears, preventing metal-to-metal contact that could lead to premature wear.

Pump Drive Housing

The flange gasket in the pump drive housing ensures that the connection between the pump and the engine is leak-free. This is particularly important in systems where pressure integrity is essential, such as in hydraulic or fuel systems.

Accessory Drive Pulley

When used with the accessory drive pulley, the flange gasket seals the interface between the pulley housing and the engine. This helps in maintaining the efficiency of the drive system by preventing any fluid leaks that could affect the pulley’s operation.

Hydraulic Drive Assembly Cover

In the hydraulic drive assembly cover, the flange gasket ensures that the hydraulic fluid remains contained within the system. This is crucial for maintaining the pressure and performance of the hydraulic components.

Intermediate Assembly Gear

For the intermediate assembly gear, the flange gasket seals the connection between the gear housing and the engine or other components. This ensures that the lubricants stay within the system, promoting efficient gear operation and longevity.

Power Take-Off Assembly Gear

In the power take-off assembly gear, the flange gasket provides a seal between the gear housing and the engine. This is important for maintaining the efficiency of the power take-off system, ensuring that power is transferred effectively without any losses due to leaks.

Power Take-Off Assembly Housing

The flange gasket in the power take-off assembly housing ensures a secure seal between the housing and the engine or other components. This is essential for maintaining the integrity of the power take-off system, preventing any fluid leaks that could affect its performance.

Fuel Transfer Pump

In the fuel transfer pump, the flange gasket seals the connection between the pump and the fuel system components. This ensures efficient fuel transfer and prevents any leaks that could lead to engine performance issues.

Sea Water and Power Take-Off Assembly Housing

For the sea water and power take-off assembly housing, the flange gasket provides a seal that prevents sea water from leaking into the engine or other components. This is vital for maintaining the integrity of the system, especially in marine applications where corrosion can be a significant issue.

Sea Water Pump Housing

Finally, in the sea water pump housing, the flange gasket ensures that the connection between the pump and the engine or cooling system is leak-free. This is important for maintaining the efficiency of the cooling system and preventing any water from entering the engine, which could cause severe damage.

Conclusion

The 3423291 Flange Gasket plays a critical role in the sealing applications within truck engines, ensuring that connections between flanged components remain sealed under various operating conditions. Its design, featuring materials that offer high resistance to temperature and pressure, ensures durability in demanding environments. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the effectiveness and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.