This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Carrier Gasket 3600470, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and engines that are integral to the functionality and efficiency of commercial vehicles. This Cummins part plays a significant role in ensuring the reliable operation of trucks.

Basic Concepts of Carrier Gaskets

Carrier gaskets are sealing components used in various machinery, including engines and transmission systems. Their primary function is to create a seal between two or more mating surfaces, preventing the leakage of fluids or gases 1. In engines, carrier gaskets are often placed between the cylinder head and the engine block, ensuring that combustion gases remain within the combustion chamber and do not escape into other parts of the engine.

Purpose of the 3600470 Carrier Gasket

This part is specifically designed to fit within the engine or transmission system of a truck. Its placement is typically between the cylinder head and the engine block, where it plays a role in maintaining the seal integrity during engine operation. This gasket helps to ensure that combustion pressures are contained, contributing to the overall efficiency and performance of the engine 2.

Key Features

The 3600470 is constructed from materials that offer durability and resistance to high temperatures and pressures. Its design includes features that enhance its sealing capabilities, such as precise cutouts and a robust composition that can withstand the rigors of commercial truck operation. These characteristics contribute to the gasket’s ability to provide a reliable seal over an extended period 3.

Benefits

Using the 3600470 offers several advantages. It provides improved sealing efficiency, which can lead to better engine performance and reduced risk of leaks. The durability of the gasket means it can withstand the demanding conditions of commercial truck use, potentially leading to longer intervals between replacements and cost savings for fleet operators 4.

Installation Process

Proper installation of the 3600470 is important for ensuring a secure fit and optimal performance. The process involves cleaning the mating surfaces to remove any debris or old gasket material, positioning the new gasket correctly, and then securing it in place according to the manufacturer’s guidelines. Tools such as torque wrenches may be required to ensure that fasteners are tightened to the specified torque settings.

Maintenance Tips

To prolong the lifespan of the 3600470, regular inspections are recommended. This includes checking for signs of wear, damage, or deformation that may indicate the need for replacement. Keeping the gasket and its mating surfaces clean and free from contaminants can also help maintain its sealing effectiveness.

Troubleshooting Common Issues

Common problems associated with carrier gaskets include leaks or failures, which can manifest as engine performance issues or visible signs of fluid or gas escape. Diagnosing these issues may involve inspecting the gasket and its seating surfaces for damage, ensuring proper installation, and checking for any external factors that could contribute to gasket failure.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a strong reputation in the commercial truck industry, Cummins products are known for their reliability, performance, and efficiency. The company’s commitment to quality and customer satisfaction has made it a preferred choice for fleet operators worldwide.

Role of Part 3600470 Carrier Gasket in Engine Systems

The 3600470 is an essential component in the assembly and operation of various engine systems. It is specifically designed to ensure a secure and leak-proof seal between multiple engine components, thereby maintaining the integrity of the engine’s internal environment.

Integration with Base Parts

When installing the base parts of an engine, the 3600470 is positioned to create a barrier that prevents oil and other fluids from seeping into areas where they could cause damage or reduce efficiency. This gasket ensures that the base parts are well-sealed, contributing to the overall stability and performance of the engine.

Application in Covers

In the context of engine covers, the 3600470 plays a significant role in sealing the cover to the engine block. This prevents any contaminants from entering the engine and ensures that the cover remains securely in place, protecting internal components from external elements.

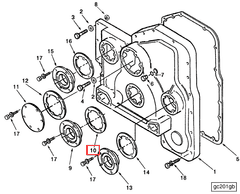

Front Gear and Housing Assemblies

For the front gear and its associated housing, the 3600470 is instrumental in maintaining the seal between the front gear housing and the front gear housing cover. This seal is vital for preventing oil leakage, which could lead to reduced lubrication and increased wear on moving parts.

Lower Engine Gasket Set

As part of the lower engine gasket set, the 3600470 works in conjunction with other gaskets to ensure a comprehensive seal across the lower section of the engine. This is particularly important for maintaining crankcase pressure and preventing oil from escaping, which is essential for the engine’s lubrication system.

Oil Seal Kit

In an oil seal kit, the 3600470 complements the oil seals by providing an additional layer of protection against oil leaks. It ensures that the oil seal kit functions effectively, maintaining the engine’s lubrication system and protecting surrounding components from oil contamination.

Conclusion

Overall, the 3600470 is a key component in ensuring the reliability and efficiency of engine systems by providing essential seals between various engine parts. Its role in preventing leaks and maintaining the correct alignment of engine components is vital for the overall performance and longevity of the engines.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Mom, G. (2023). The Evolution of Automotive Engineering: A Handbook. SAE International.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.