This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

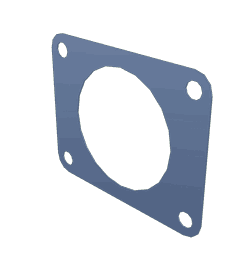

The 4066496 Flange Gasket, a component designed for use in commercial trucks and manufactured by Cummins, plays a role in ensuring the integrity of connections within the truck’s engine or exhaust system. Cummins, a well-established manufacturer in the automotive industry, is known for its expertise in diesel engine technology and commitment to quality and innovation 1.

Basic Concepts of Flange Gaskets

Flange gaskets are sealing components used in mechanical systems to create a tight seal between pipes, valves, and fittings. They work by filling the space between two or more mating surfaces, preventing the leakage of fluids or gases. The effectiveness of a flange gasket depends on its material, design, and the conditions under which it operates 2.

Purpose of the 4066496 Flange Gasket

The 4066496 Flange Gasket is designed to seal flanged connections in the engine or exhaust system of a truck. Its role is to maintain the integrity of these connections, ensuring that there are no leaks of exhaust gases or engine fluids. This gasket is specifically tailored to meet the demands of commercial truck operations, where durability and reliability are paramount 3.

Key Features

The 4066496 Flange Gasket features a composition and design that enhance its performance and durability. It is made from materials that can withstand high temperatures and pressures, common in engine and exhaust systems. Its design ensures a snug fit in flanged connections, contributing to its sealing efficiency. Additionally, it may possess unique attributes that further improve its resistance to wear and environmental factors 4.

Benefits

The use of the 4066496 Flange Gasket offers several benefits. It provides improved sealing efficiency, ensuring that connections remain leak-free under operating conditions. Its resistance to high temperatures and pressures makes it suitable for the demanding environment of a truck’s engine or exhaust system. Furthermore, its durability ensures longevity, reducing the need for frequent replacements 5.

Installation Considerations

When installing the 4066496 Flange Gasket, it is important to follow guidelines and best practices to ensure its effectiveness. This includes adhering to torque specifications for tightening flanged connections, preparing surfaces to ensure a proper seal, and verifying compatibility with other components in the system. Proper installation is key to maximizing the gasket’s performance and lifespan 6.

Troubleshooting Common Issues

Common problems associated with flange gaskets include leaks or failure. These issues can often be traced back to improper installation, wear and tear, or exposure to extreme conditions. Troubleshooting steps may involve inspecting the gasket and mating surfaces for damage, ensuring proper torque has been applied, and replacing the gasket if necessary 7.

Maintenance Tips

Regular maintenance of the 4066496 Flange Gasket is important for ensuring its continued performance. This includes inspecting the gasket for signs of wear or damage at recommended intervals and replacing it when necessary. Keeping the gasket and its mating surfaces clean and free of debris can also contribute to its longevity and effectiveness 8.

Cummins Overview

Cummins Inc. has a long history of innovation and quality in the diesel engine manufacturing sector. The company’s commitment to excellence is evident in its wide range of products, including the 4066496 Flange Gasket. Cummins’ expertise in engine technology and its dedication to meeting the needs of the automotive industry underscore its reputation as a trusted manufacturer 9.

Compatibility with Cummins Engines

The Flange Gasket part number 4066496, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines, ensuring a secure seal and preventing leaks. This gasket is crucial for maintaining the integrity of the engine’s connections, particularly in high-pressure and high-temperature environments.

QSK60 and QSK60 G Engines

The QSK60 and QSK60 G engines benefit from the precise fit and durability of the 4066496 Flange Gasket. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The gasket’s compatibility with these models ensures that the engine’s flange connections remain airtight, contributing to overall efficiency and longevity.

CM2358 and K110 Engines

Similarly, the CM2358 and K110 engines are designed to work optimally with the 4066496 Flange Gasket. These engines are typically used in industrial and marine applications, where maintaining a tight seal is critical. The gasket’s material and design are tailored to withstand the specific operational demands of these engines, ensuring that they perform reliably under various conditions.

Grouping for Efficiency

When considering the QSK60, QSK60 G, CM2358, and K110 engines, it is evident that the 4066496 Flange Gasket is a versatile component. Its design allows it to be used across different engine models, simplifying maintenance and inventory management for operators. This compatibility ensures that the gasket can be easily sourced and installed, reducing downtime and enhancing operational efficiency.

Role of the 4066496 Flange Gasket in Engine Systems

In the context of engine systems, the 4066496 Flange Gasket is a component that ensures the integrity and efficiency of various engine operations.

Cooling System Gasket Kit

Within the cooling system gasket kit, the 4066496 Flange Gasket is positioned between the engine block and the thermostat housing. Its primary function is to create a seal that prevents coolant leakage. This seal is vital for maintaining the proper flow of coolant, which is necessary for regulating engine temperature and preventing overheating. The gasket’s material is chosen for its ability to withstand high temperatures and pressures, ensuring a durable and reliable seal over the lifespan of the engine.

Housing

When installed in the housing, the 4066496 Flange Gasket serves to seal the connection points where different housing components meet. This is particularly important in the thermostat housing, where the gasket ensures that no coolant escapes during engine operation. The gasket’s precise fit and material properties are designed to accommodate the thermal expansion and contraction that occur within the housing, maintaining a consistent seal under varying operating conditions.

Thermostat

The interaction between the 4066496 Flange Gasket and the thermostat is another key aspect of its role. The gasket is placed between the thermostat and the engine block or housing, ensuring that the thermostat can operate within a sealed environment. This seal is necessary for the thermostat to function correctly, opening and closing at the appropriate temperatures to regulate coolant flow. The gasket helps maintain the pressure differential required for the thermostat to operate efficiently, contributing to the overall thermal management of the engine.

Conclusion

The 4066496 Flange Gasket is a critical component in the maintenance and operation of Cummins engines, particularly in commercial truck applications. Its design and material properties ensure durability, reliability, and efficiency in sealing flanged connections within engine and exhaust systems. Proper installation, maintenance, and understanding of its role in engine systems are essential for maximizing its performance and lifespan.

-

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9N CM2380 L142B, Bulletin Number 5660009.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9N CM2380 L142B, Bulletin Number 5660009.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.