4322911

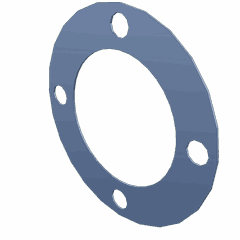

Flange Gasket

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4322911 Flange Gasket, manufactured by Cummins, is a critical component in the commercial truck industry. This gasket is specifically designed for use in commercial trucks, where it ensures the efficient operation of the vehicle’s engine or exhaust system.

Basic Concepts of Flange Gaskets

Flange gaskets are sealing devices used between mating surfaces in mechanical systems. Their primary function is to create a tight seal, preventing the leakage of fluids or gases. This is achieved through the gasket’s ability to conform to the surfaces it is placed between, ensuring no gaps are left through which substances could escape 1.

Purpose of the 4322911 Flange Gasket

The 4322911 Flange Gasket is utilized in the operation of trucks, typically within the engine or exhaust system. Its placement is crucial for maintaining the integrity of the system by ensuring a secure seal between components. This gasket helps in preventing the escape of exhaust gases or engine fluids, thereby contributing to the overall efficiency and safety of the truck’s operation 2.

Key Features

The 4322911 Flange Gasket is characterized by several key features that enhance its performance and durability. These include its material composition, which is designed to withstand the high temperatures and pressures typical of engine and exhaust systems. The gasket’s design specifications are tailored to fit precisely within the truck’s engine or exhaust system, ensuring a reliable seal. Additionally, any unique attributes, such as reinforced edges or special coatings, further contribute to its effectiveness and longevity 3.

Benefits

Utilizing the 4322911 Flange Gasket offers several advantages. These include improved sealing efficiency, which is vital for the optimal operation of the truck’s engine and exhaust system. The gasket’s resistance to high temperatures and pressures ensures it can withstand the demanding conditions of commercial truck use. Furthermore, its durability in harsh operating environments contributes to the longevity of the gasket, reducing the need for frequent replacements.

Installation Process

Proper installation of the 4322911 Flange Gasket is crucial for ensuring a secure and effective seal. The process involves several steps, including preparing the mating surfaces to ensure they are clean and free of any debris that could compromise the seal. Tools required for installation may include gasket scrapers and torque wrenches to ensure the gasket is properly seated and the components are tightened to the manufacturer’s specifications. Following best practices during installation helps in achieving the desired sealing performance.

Troubleshooting Common Issues

Common problems that may arise with flange gaskets include leaks or failures, which can be caused by improper installation, wear and tear, or exposure to extreme conditions. Troubleshooting these issues involves inspecting the gasket and mating surfaces for signs of damage or misalignment. Addressing these problems promptly can help in maintaining the efficiency and safety of the truck’s engine and exhaust system.

Maintenance Tips

Regular maintenance of the 4322911 Flange Gasket is recommended to ensure its continued effectiveness. This includes periodic inspections for signs of wear or damage, cleaning the gasket and mating surfaces to remove any buildup that could affect the seal, and considering replacement if the gasket shows significant signs of deterioration. Adhering to these maintenance practices helps in prolonging the gasket’s lifespan and ensuring the reliable operation of the truck.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the commercial truck industry, Cummins is known for its commitment to quality and innovation. The company’s extensive product range and reputation for reliability make it a preferred choice among commercial truck manufacturers and operators.

Cummins Flange Gasket 4322911 Compatibility with Engine Models

The Cummins Flange Gasket 4322911 is designed to fit seamlessly within a range of Cummins engine models, ensuring optimal sealing and performance. This gasket is engineered to meet the specific requirements of various engine configurations, providing a reliable barrier against leaks and maintaining system integrity.

QSK50 Series

The QSK50 series engines, known for their robust performance and reliability, are compatible with the 4322911 Flange Gasket. This gasket is crucial in maintaining the seal between the engine’s flange connections, ensuring that the engine operates efficiently and safely.

CM2150 Series

The CM2150 series engines, which are designed for heavy-duty applications, also benefit from the use of the 4322911 Flange Gasket. This gasket is essential in preventing leaks and ensuring that the engine’s components remain securely connected, contributing to the overall durability and performance of the engine.

MCRS Series

The MCRS series engines, which are engineered for marine applications, require the 4322911 Flange Gasket to maintain the integrity of their flange connections. This gasket is designed to withstand the harsh marine environment, providing a reliable seal that helps protect the engine from water and other contaminants.

Each of these engine series relies on the 4322911 Flange Gasket to ensure that their flange connections are properly sealed, contributing to the overall efficiency and longevity of the engine.

Role of Part 4322911 Flange Gasket in Engine Systems

The part 4322911 Flange Gasket is an essential component in ensuring the integrity and efficiency of various engine systems. Its primary function is to create a secure seal between flanged connections, preventing leaks and maintaining system pressure.

Integration with Engine Components

Arrangement

In the arrangement of engine components, the Flange Gasket ensures that all flanged connections are sealed properly. This is particularly important in high-pressure systems where even minor leaks can lead to significant performance issues.

Pressure Regulator Valve

When integrated with the Pressure Regulator Valve, the Flange Gasket helps maintain consistent pressure levels within the system. A well-sealed connection ensures that the valve operates within its specified parameters, contributing to stable engine performance.

Fuel Transfer Kit

In the Fuel Transfer Kit, the Flange Gasket plays a vital role in sealing the connections between various components. This ensures that fuel is transferred efficiently without any leaks, which is essential for the reliable operation of the engine.

Fuel Transfer Right Hand Engine Kit

For the Fuel Transfer Right Hand Engine Kit, the Flange Gasket is used to seal connections in the right-hand engine configuration. This ensures that fuel is delivered to the engine components without any interruptions, enhancing overall engine efficiency.

Service Kit

In a Service Kit, the Flange Gasket is often included to replace worn-out or damaged gaskets during maintenance. This ensures that all connections are re-sealed properly, maintaining the integrity of the engine system post-service.

Conclusion

The 4322911 Flange Gasket is a vital component in the operation of commercial trucks, ensuring the efficient and safe operation of engine and exhaust systems. Its design, compatibility with various Cummins engine models, and role in maintaining system integrity highlight its importance in the commercial truck industry. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.