The 4900591 Breather Gasket, manufactured by Cummins, is a component designed for use in commercial truck maintenance. Cummins, a well-established name in the industry, produces this gasket to ensure the efficient operation of truck engines. The breather gasket is integral to maintaining the engine’s performance and longevity.

Basic Concepts of Breather Gaskets

Breather gaskets are components used in machinery to allow air to enter and exit the engine crankcase. Their general function is to regulate pressure within the crankcase, ensuring that the engine operates efficiently and safely. By allowing controlled air exchange, breather gaskets help to prevent the buildup of pressure that could lead to leaks or other engine issues 1.

Purpose of the 4900591 Breather Gasket

The 4900591 Breather Gasket plays a specific role in the operation of a truck by facilitating the proper ventilation of the engine crankcase. It ensures that air can enter and exit the crankcase as needed, which helps maintain optimal pressure levels. This function is vital for the engine’s overall efficiency and safety, as it prevents the accumulation of contaminants and moisture that could otherwise harm the engine components 2.

Key Features

The 4900591 Breather Gasket is designed with several key features that enhance its performance. It is composed of durable materials that can withstand the high temperatures and pressures within the engine environment. The gasket’s design includes precise dimensions and a robust construction to ensure a secure fit and effective sealing. Additionally, it may incorporate unique characteristics such as anti-vibration properties to maintain stability during engine operation.

Benefits

Using the 4900591 Breather Gasket offers several benefits. It contributes to improved engine performance by ensuring proper crankcase ventilation, which helps maintain clean oil and reduces the risk of engine wear. The gasket’s durable construction promotes longevity, reducing the frequency of replacements. Furthermore, its reliable design enhances the overall reliability of the engine system, leading to fewer maintenance issues and downtime.

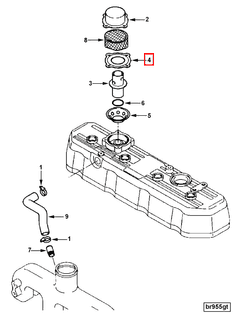

Installation Process

Installing the 4900591 Breather Gasket requires careful attention to detail. Begin by ensuring the engine is cool and the old gasket is removed. Clean the mating surfaces to remove any debris or old gasket material. Position the new gasket onto the crankcase, ensuring it is aligned correctly. Use the appropriate tools to secure the gasket in place, following the manufacturer’s guidelines for torque specifications. Finally, perform a visual inspection to confirm the gasket is properly installed and sealed.

Troubleshooting Common Issues

Common problems associated with breather gaskets include leaks, contamination, and blockages. To address these issues, regularly inspect the gasket for signs of wear or damage. If a leak is detected, replace the gasket promptly to prevent further engine damage. Ensure the breather system is free from contaminants by cleaning or replacing filters as needed. If blockages occur, check for obstructions in the breather lines and clear them to restore proper airflow.

Maintenance Tips

To ensure the longevity and optimal performance of the 4900591 Breather Gasket, follow these maintenance tips. Regularly inspect the gasket for signs of wear, cracks, or leaks. Clean the breather system components to prevent the accumulation of contaminants. Replace the gasket according to the manufacturer’s recommended intervals or if any damage is detected. Additionally, monitor the engine’s performance and address any issues promptly to maintain efficient operation.

About Cummins

Cummins is a renowned manufacturer with a long-standing reputation in the industry. Founded in 1919, Cummins has a history of innovation and quality in engine technology. The company is known for producing reliable and high-performance engines and components, including the 4900591 Breather Gasket. Cummins’ commitment to excellence and customer satisfaction has established them as a trusted name in the commercial truck and engine industry.

Role of Part 4900591 Breather Gasket in Engine Systems

The 4900591 Breather Gasket is an essential component in the efficient operation of engine systems, specifically within the context of the breather, crankcase, and crankcase breather.

In the breather system, the 4900591 Breather Gasket ensures a secure seal, preventing the escape of unwanted gases and contaminants while allowing necessary ventilation. This balance is vital for maintaining optimal pressure within the engine’s breather system, which in turn supports efficient combustion and reduces the risk of engine wear.

Within the crankcase, the 4900591 Breather Gasket plays a significant role by sealing the interface between the crankcase and other components. This seal is important for containing the crankcase pressure, which is generated during engine operation. Proper sealing helps in managing the crankcase ventilation system effectively, ensuring that blow-by gases—composed of unburned fuel, combustion byproducts, and moisture—are properly routed away from the crankcase. This prevents the accumulation of sludge and contaminants, which can lead to decreased engine performance and increased wear on moving parts.

In the crankcase breather system, the 4900591 Breather Gasket facilitates the release of pressure built up within the crankcase while preventing the ingress of external contaminants. This is achieved by creating a reliable seal that allows gases to escape through designated pathways, typically leading to the intake manifold where they can be re-burned. The effective functioning of the crankcase breather system, supported by the 4900591 Breather Gasket, is essential for maintaining clean oil, efficient engine operation, and prolonged engine life.

Overall, the 4900591 Breather Gasket is a key component in ensuring the breather, crankcase, and crankcase breather systems operate harmoniously, contributing to the overall efficiency and longevity of the engine.

Conclusion

The 4900591 Breather Gasket is a critical component in the maintenance and operation of commercial truck engines. Its role in regulating pressure within the crankcase, preventing contaminant accumulation, and ensuring efficient engine performance cannot be overstated. Regular maintenance and prompt replacement of this part are essential for the longevity and reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.