This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Injector Fuel Supply Tube, part number 4900592, is a critical component in the fuel delivery system of various Cummins engines. This part ensures that fuel is efficiently and accurately delivered to the injectors, which is essential for optimal engine performance and efficiency 1.

Basic Concepts of Injector Fuel Supply Tubes

Injector fuel supply tubes are fundamental components within a vehicle’s fuel system. Their primary function is to transport fuel from the fuel tank or fuel rail to the injectors. This process is crucial for maintaining consistent fuel pressure and flow, which directly influences engine performance 2.

Purpose and Role in Truck Operation

The Injector Fuel Supply Tube 4900592 serves a specific purpose within a truck’s fuel system. It facilitates the delivery of fuel from the fuel rail to the injectors, ensuring that each injector receives the precise amount of fuel needed for combustion. This component plays a role in maintaining the correct fuel pressure and flow, which is essential for the engine’s operation 3.

Key Features

The Injector Fuel Supply Tube 4900592 is designed with several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity. The design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube is engineered to withstand high pressure and temperature, making it suitable for the demanding conditions of heavy-duty truck operation 4.

Benefits

Using the Injector Fuel Supply Tube 4900592 offers several benefits. It improves fuel delivery efficiency, ensuring that the injectors receive the correct amount of fuel under the right pressure. This leads to enhanced engine performance, with smoother operation and increased power output. The component’s durable construction and resistance to wear also contribute to increased reliability, reducing the likelihood of fuel system failures 5.

Installation and Compatibility

Proper installation of the Injector Fuel Supply Tube 4900592 is crucial for ensuring optimal performance. It should be installed according to the manufacturer’s guidelines, with attention to securing all connections and ensuring there are no leaks. Compatibility with various truck models and engine types is an important consideration, ensuring that the component fits and functions correctly within the specific fuel system 6.

Troubleshooting and Maintenance

Common issues with injector fuel supply tubes include leaks and blockages. Regular inspection and maintenance can help identify and address these problems early, ensuring continued efficient operation. Maintenance tips include checking for signs of wear or damage, ensuring all connections are secure, and replacing the component if any issues are detected. This proactive approach helps maintain optimal performance and longevity of the fuel supply tube 7.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, natural gas engines, and related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the industry. The company is committed to producing high-quality automotive components that enhance vehicle performance and reliability. Their expertise and dedication to excellence are reflected in products like the Injector Fuel Supply Tube 4900592, which are designed to meet the demanding requirements of heavy-duty truck operation 8.

Compatibility with Cummins Engines

A1400 and A1700 Engines

The Injector Fuel Supply Tube (4900592) is designed to fit seamlessly with the A1400 and A1700 engines. These engines are known for their reliability and efficiency, often used in a variety of applications from industrial machinery to power generation. The part’s design ensures a secure and leak-free connection, which is crucial for maintaining the engine’s performance and longevity 9.

A2000 and A2300 Engines

Similarly, the Injector Fuel Supply Tube (4900592) is also compatible with the A2000 and A2300 engines. These engines are part of Cummins’ higher power output range, often utilized in heavy-duty applications such as construction equipment and large vehicles. The part’s precision engineering guarantees that it will fit these engines without any modifications, ensuring that the fuel supply remains uninterrupted and consistent 10.

Importance of the Injector Fuel Supply Tube

The Injector Fuel Supply Tube (4900592) plays a pivotal role in the overall functionality of the engine’s fuel system. By providing a reliable pathway for fuel to reach the injectors, it helps maintain the correct fuel pressure and flow rate, which are critical for the engine’s combustion process. This part is designed to withstand the high pressures and temperatures associated with engine operation, ensuring durability and reliability over time 11.

Installation and Maintenance

When installing the Injector Fuel Supply Tube (4900592), it is essential to follow the manufacturer’s guidelines to ensure a proper fit and function. Regular maintenance checks should be performed to inspect for any signs of wear, leaks, or damage. Any issues with the fuel supply tube can lead to inefficient fuel delivery, which can negatively impact engine performance and efficiency 12.

Role of Part 4900592 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 4900592, is an integral component in the fuel delivery system of an engine. Its primary function is to transport fuel from the fuel rail to the injectors, ensuring a consistent and precise fuel supply to each cylinder. This part interfaces with several key components within the engine system to maintain optimal performance and efficiency 13.

Interaction with the Fuel Rail

The Injector Fuel Supply Tube connects directly to the fuel rail, which is a pressurized conduit that distributes fuel to each injector. The tube ensures that fuel is delivered under the correct pressure, which is essential for the injectors to atomize the fuel properly. This atomization is vital for efficient combustion within the cylinders 14.

Coordination with Injectors

Each injector is supplied with fuel through the Injector Fuel Supply Tube. The tube must be securely fitted to prevent any leaks, which could lead to inconsistent fuel delivery and potential engine misfires. The precise fit and seal of the tube with the injectors are necessary to maintain the engine’s performance and fuel efficiency 15.

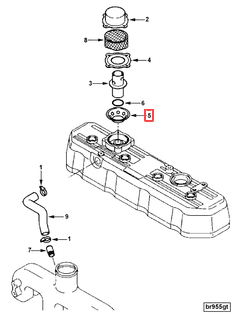

Relationship with the Crankcase and Crankcase Breather

While the Injector Fuel Supply Tube is primarily part of the fuel system, its efficient operation indirectly affects the crankcase and crankcase breather system. Proper fuel delivery and combustion reduce the likelihood of unburnt fuel entering the crankcase, which can contaminate the oil and lead to increased wear on moving parts. The crankcase breather, which allows pressure to be released from the crankcase, operates more effectively when the engine runs smoothly, a condition supported by consistent fuel supply via the Injector Fuel Supply Tube 16.

Impact on the Breather System

The breather system, including the crankcase breather, plays a role in maintaining the engine’s internal pressure balance. Efficient operation of the Injector Fuel Supply Tube ensures that the engine runs smoothly, which in turn helps the breather system function correctly by preventing excessive pressure build-up within the crankcase. This interplay between fuel delivery and breather systems underscores the importance of each component working harmoniously to ensure the engine’s longevity and performance 17.

Conclusion

The Cummins Injector Fuel Supply Tube, part number 4900592, is a vital component in the fuel delivery system of Cummins engines. Its role in ensuring efficient and accurate fuel delivery to the injectors is crucial for maintaining optimal engine performance and efficiency. Proper installation, regular maintenance, and understanding its interaction with other engine components are essential for the longevity and reliability of this Cummins part.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 2883376.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.