This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5256214 Gasket is a critical component in commercial truck engines, designed to ensure proper sealing between engine components. This sealing is essential for maintaining the integrity of the engine’s operating environment, preventing leaks, and maintaining pressure, which contributes to the engine’s overall efficiency and reliability 4.

Basic Concepts of Gaskets

Gaskets are sealing devices used between mating surfaces in bolted joints to prevent fluid or gas leakage and maintain system pressure. They are made from various materials like rubber, cork, graphite, and metal, chosen based on application requirements such as temperature, pressure, and the type of fluid or gas being sealed 1.

Purpose of the 5256214 Gasket

The Cummins 5256214 Gasket specifically seals the connection between the cylinder head and the engine block. This sealing is vital for maintaining cylinder compression for efficient combustion and preventing coolant and oil mixing, which could damage the engine 2.

Key Features

This Cummins part is characterized by its robust design and composite material, offering flexibility and durability. Its precise cutouts and contours match the engine’s surface for a snug fit and effective seal. The gasket is resistant to high temperatures and pressures, enhancing its performance in demanding engine environments 3.

Benefits

Using the Cummins 5256214 Gasket improves engine efficiency by maintaining combustion pressures and preventing leaks. Its durability and reliability in sealing applications extend the engine’s lifespan. The gasket’s design and material properties allow it to withstand harsh conditions within a commercial truck engine, providing consistent performance over time 4.

Installation Considerations

Proper installation of the 5256214 is crucial for optimal performance and longevity. It should be installed in a clean, dry environment to prevent contamination. The mating surfaces should be free of debris and imperfections, and torque specifications provided by the manufacturer should be followed to ensure proper compression without overtightening 1.

Troubleshooting Common Issues

Gasket failure can cause engine problems like loss of compression, coolant leaks, and oil contamination. Diagnostic methods include visual inspection for leakage signs, pressure testing, and analyzing engine performance data. Solutions for maintaining the gasket’s integrity include regular inspection, proper installation, and replacement at recommended service intervals or when wear signs are detected 2.

Maintenance Tips

Routine checks and maintenance practices are essential for prolonging the life of the 5256214 and ensuring continued engine performance. This includes regular inspections for wear or damage, proper torquing during reassembly, and replacing the gasket as part of scheduled engine maintenance or when performance issues arise 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history dating back to 1919, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s commitment to innovation and customer satisfaction has made it a preferred choice for engine components, including gaskets like the 5256214 4.

Role of 5256214 Gasket in Engine Systems

The 5256214 Gasket is instrumental in ensuring the efficient operation of various engine components, particularly within air compressor systems. This gasket creates a secure seal between mating surfaces, preventing leaks and maintaining system integrity.

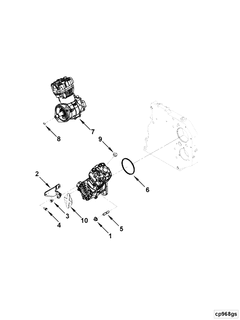

Air Compressor

In an air compressor, the 5256214 seals the combustion chamber, ensuring that compressed air does not escape. This seal is vital for maintaining the pressure required for efficient air compression and delivery 1.

Air Compressor Kit

When integrated into an air compressor kit, the 5256214 ensures that all components within the kit operate in a sealed environment. This prevents air leaks, which could reduce the effectiveness of the compressor and lead to increased energy consumption 2.

Compressor

For standalone compressor units, the gasket is essential in maintaining the structural integrity of the compressor. It seals the connections between the compressor body and other attached components, such as manifolds and valves. This ensures that the compressed air is delivered consistently without any loss of pressure 3.

Air Systems

In broader air systems that include multiple compressors and distribution networks, the 5256214 contributes to the overall efficiency of the system. By ensuring that each compressor unit operates within a sealed environment, it helps maintain the desired air pressure throughout the system, reducing the need for frequent adjustments and repairs 4.

Conclusion

The Cummins 5256214 Gasket plays a vital role in the efficient and reliable operation of commercial truck engines and air compressor systems. Its design, material composition, and precise fitting ensure effective sealing, preventing leaks and maintaining system pressure. Proper installation, regular maintenance, and timely replacement are key to maximizing the gasket’s performance and longevity, contributing to the overall efficiency and reliability of the engine systems it serves.

-

Yushu Wang, Introduction to Engine Valvetrains, SAE International, 2007.

↩ ↩ ↩ -

Douglas R. Fehan, Design of Racing and High-Performance Engines 2004-2013, SAE International, 2013.

↩ ↩ ↩ -

Konrad Reif Ed, Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Springer, 2014.

↩ ↩ ↩ -

G.K. Awari, V.S. Kumbhar, and R.B. Tirpude, Automotive Systems Principles and Practice, CRC Press, 2011.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.