5558450

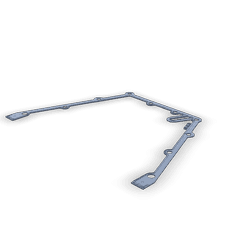

Lubricating Oil Pump Gasket

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Lubricating Oil Pump Gasket (Part #5558450) is designed to facilitate the efficient operation of commercial truck engines. It ensures a secure seal within the oil pump system, which is essential for maintaining the proper flow and pressure of lubricating oil throughout the engine. This part contributes significantly to the overall performance and longevity of the engine by ensuring effective lubrication 1.

Basic Concepts of Lubricating Oil Pump Gaskets

A Lubricating Oil Pump Gasket is a sealing component positioned between the oil pump and the engine block or other mating surfaces. Its function is to create a barrier that prevents oil leakage from the pump while allowing it to circulate under pressure. This gasket is integral to the oil pump system, as it helps maintain the necessary pressure and flow of oil, which is vital for lubricating moving parts within the engine, reducing friction, and dissipating heat 2.

Role and Function in Truck Operation

The Lubricating Oil Pump Gasket plays a role in the operation of a truck by ensuring that the oil pump can maintain a consistent seal. This seal is necessary for the pump to generate and sustain the required oil pressure. Proper sealing and pressure maintenance within the oil pump system are fundamental for the efficient distribution of oil to critical engine components, such as bearings, pistons, and camshafts. This, in turn, supports the engine’s smooth operation and durability 3.

Key Features

The Cummins Lubricating Oil Pump Gasket is characterized by several key features that enhance its performance and durability. These include a material composition designed to withstand high temperatures and pressures, precise design specifications that ensure a perfect fit within the oil pump system, and unique attributes such as reinforced edges or multi-layered construction that improve its sealing capabilities. These features contribute to the gasket’s ability to provide reliable service under demanding conditions.

Benefits of Using Cummins Lubricating Oil Pump Gasket

Utilizing the Cummins Lubricating Oil Pump Gasket offers several benefits. These include improved engine performance due to consistent oil pressure and flow, enhanced reliability as a result of its durable construction, and potential cost savings over time. The gasket’s ability to maintain a secure seal reduces the risk of oil leaks, which can lead to engine damage and increased maintenance costs. Additionally, its longevity can contribute to fewer replacement cycles, further reducing operational expenses.

Installation and Maintenance

Proper installation of the Lubricating Oil Pump Gasket is crucial for its effectiveness. Recommended procedures include ensuring the mating surfaces are clean and free of debris before installation, using the correct torque specifications when securing the oil pump, and verifying the gasket’s position and condition during the installation process. Maintenance tips to prolong the gasket’s lifespan include regular inspections for signs of wear or damage, adhering to the manufacturer’s recommended oil change intervals, and addressing any oil leaks promptly to prevent contamination and potential damage to the gasket.

Troubleshooting Common Issues

Common problems associated with Lubricating Oil Pump Gaskets include leaks or failures, which can arise from improper installation, wear and tear, or exposure to extreme conditions. Troubleshooting steps to diagnose and address these issues effectively involve inspecting the gasket for visible damage, checking the mating surfaces for cleanliness and proper alignment, and ensuring that the oil pump and related components are functioning correctly. Addressing these issues promptly can help maintain the integrity of the oil pump system and prevent more severe engine problems.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive industry, known for its history of innovation and commitment to producing high-quality components for commercial vehicles. With a reputation for reliability and performance, Cummins has been a trusted name among fleet operators and maintenance professionals. The company’s dedication to excellence is reflected in its wide range of products, including the Lubricating Oil Pump Gasket, which is designed to meet the demanding requirements of commercial truck engines.

Cummins Lubricating Oil Pump Gasket 5558450 Compatibility

The Cummins Lubricating Oil Pump Gasket part number 5558450 is designed to fit a variety of Cummins engines. This gasket is essential for ensuring a proper seal between the oil pump and the engine block, preventing oil leaks and maintaining optimal engine performance. Below is a detailed description of its compatibility with the listed engines:

ISG11 CM2880 G108 and ISG12 CM2880 G107

The ISG11 CM2880 G108 and ISG12 CM2880 G107 engines are part of the Cummins ISG series, known for their reliability and efficiency. The 5558450 gasket is engineered to fit these engines, ensuring a secure seal that prevents oil from leaking out of the pump housing.

QSG12 CM2880 G112

The QSG12 CM2880 G112 engine is another variant in the Cummins QSG series, which is designed for high-performance applications. The 5558450 gasket is compatible with this engine, providing the necessary sealing properties to maintain engine integrity and performance.

QSG12/X12 CM2350 G110

The QSG12/X12 CM2350 G110 engine combines features from both the QSG and X12 series. The 5558450 gasket is suitable for this engine, ensuring that the oil pump operates efficiently without any leaks.

X11 CM2670 X126B and X12 CM2350 X119B

The X11 CM2670 X126B and X12 CM2350 X119B engines are part of the Cummins X12 series, which is known for its durability and power. The 5558450 gasket is designed to fit these engines, providing a reliable seal that helps maintain engine health.

X12 CM2670 X121B and X12N CMMDG1 X143B

The X12 CM2670 X121B and X12N CMMDG1 X143B engines are also part of the Cummins X12 series. The 5558450 gasket is compatible with these engines, ensuring that the oil pump functions correctly and that there are no oil leaks.

X13 CM2670 X122B

The X13 CM2670 X122B engine is another variant in the Cummins X12 series. The 5558450 gasket is designed to fit this engine, providing a secure seal that is crucial for maintaining engine performance and longevity.

By ensuring that the 5558450 gasket fits these engines, Cummins guarantees that the oil pump operates efficiently, reducing the risk of oil leaks and maintaining the engine’s overall health.

Conclusion

The Cummins Lubricating Oil Pump Gasket (Part #5558450) is a critical component for the efficient operation of commercial truck engines. Its role in maintaining a secure seal within the oil pump system ensures the proper flow and pressure of lubricating oil, contributing to the engine’s performance and longevity. With its durable construction and compatibility with various Cummins engines, this part is essential for maintaining optimal engine health and reducing maintenance costs.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.