3008400

Hydraulic Pump Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

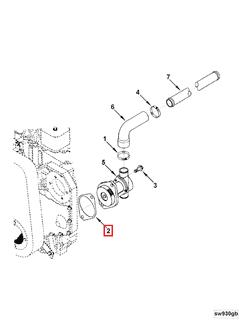

The Cummins Hydraulic Pump Gasket 3008400 is a critical component designed to facilitate the operation of hydraulic systems in commercial trucks. This gasket ensures the hydraulic pump functions correctly by providing a seal that maintains system pressure and prevents fluid leaks. Cummins, a well-regarded manufacturer in the industry, produces this part to meet the demanding requirements of commercial vehicle applications.

Basic Concepts of Hydraulic Pump Gaskets

Hydraulic pump gaskets are components used to seal the various parts of a hydraulic system. Their function is to create a barrier that prevents hydraulic fluid from leaking out while allowing the system to maintain the necessary pressure for operation. Proper sealing is essential for maintaining system efficiency, as leaks can lead to a loss of pressure, reduced performance, and potential damage to the hydraulic components. The integrity of the gasket directly influences the overall reliability and effectiveness of the hydraulic system 1.

Role of the 3008400 Hydraulic Pump Gasket in Truck Operation

The 3008400 Hydraulic Pump Gasket functions within the hydraulic system of a truck by sealing the hydraulic pump, which is responsible for generating the pressure needed to operate hydraulic components such as brakes, steering systems, and suspension. By maintaining a secure seal, this gasket helps ensure that the hydraulic pump operates efficiently, preserving system pressure and preventing fluid leaks. This, in turn, supports the consistent performance of the truck’s hydraulic systems, contributing to safer and more reliable vehicle operation 2.

Key Features

The 3008400 Hydraulic Pump Gasket is characterized by several key features that enhance its performance and durability. It is composed of materials selected for their ability to withstand the high pressures and temperatures typical of hydraulic systems. The design of the gasket includes precise dimensions and surface finishes that ensure a tight seal. Additionally, any unique attributes, such as reinforced edges or specialized coatings, further contribute to its effectiveness in demanding applications.

Benefits

Using the 3008400 Hydraulic Pump Gasket offers several benefits. It contributes to improved system reliability by ensuring a consistent seal, which helps maintain hydraulic pressure and prevent leaks. Enhanced performance of the hydraulic pump and associated components is another advantage, as the gasket’s design and material properties support efficient operation under various conditions. Furthermore, the durability of the gasket contributes to the longevity of the hydraulic pump and the overall hydraulic system, reducing the need for frequent replacements and maintenance 3.

Troubleshooting and Maintenance

Common issues associated with hydraulic pump gaskets include symptoms such as fluid leaks, decreased system pressure, and unusual noises from the hydraulic pump. These symptoms may indicate gasket failure or wear. Diagnosis involves inspecting the gasket for signs of damage, such as cracks or deformation, and checking the hydraulic system for leaks. Regular maintenance practices, such as periodic inspection of the gasket and hydraulic system, cleaning components to remove contaminants, and replacing the gasket according to the manufacturer’s recommendations, are important for ensuring the longevity and effectiveness of the gasket.

About Cummins

Cummins Inc. is a company with a history of innovation and expertise in diesel engines and related technologies. Founded in 1919, Cummins has established itself as a leader in the commercial vehicle industry, known for its commitment to quality and innovation. The company’s product lineup includes a wide range of engines, powertrains, and components designed to meet the needs of various industries, from transportation to construction. Cummins’ dedication to advancing technology and improving efficiency has made it a trusted name among professionals in the field.

Cummins Hydraulic Pump Gasket 3008400 Compatibility

The Cummins Hydraulic Pump Gasket 3008400 is a critical component designed to ensure the proper sealing and operation of the hydraulic pump in various Cummins engine models. This gasket is engineered to fit seamlessly with a range of Cummins engines, providing a reliable barrier against leaks and maintaining system integrity.

Engine Compatibility

4B3.9, 6B5.9, 6C8.3, B3.9 G, B5.9 G, B5.9 GAS PLUS CM556, C GAS PLUS CM556, C8.3 G, G5.9, G5.9 CM558, G8.3, G8.3 CM558, GTA8.3 CM558

The Hydraulic Pump Gasket 3008400 is compatible with several models within this group, including the 4B3.9, 6B5.9, 6C8.3, B3.9 G, B5.9 G, B5.9 GAS PLUS CM556, C GAS PLUS CM556, C8.3 G, G5.9, G5.9 CM558, G8.3, G8.3 CM558, and GTA8.3 CM558. These engines, known for their robust performance and reliability, benefit from the precise fit and durability of this gasket.

ISB CM550, ISB5.9G CM2180, ISC CM554, ISL CM554, ISM CM570, ISM CM570/870, ISM CM876, ISM11 CM876 SN, ISX12 CM2350 X102, ISX12 G CM2180 EJ, ISX12/ISX11.9 CM2250

This gasket also fits the ISB CM550, ISB5.9G CM2180, ISC CM554, ISL CM554, ISM CM570, ISM CM570/870, ISM CM876, ISM11 CM876 SN, ISX12 CM2350 X102, ISX12 G CM2180 EJ, and ISX12/ISX11.9 CM2250 engines. These models are part of Cummins’ advanced engine lineup, designed for high performance and efficiency. The gasket’s compatibility with these engines ensures optimal hydraulic system performance and longevity.

K19

Lastly, the Hydraulic Pump Gasket 3008400 is also suitable for the K19 engine. This model, known for its reliability and power, benefits from the gasket’s precise fit and high-quality construction, ensuring effective sealing and system integrity.

By ensuring a proper fit with these engines, the Cummins Hydraulic Pump Gasket 3008400 plays a vital role in maintaining the hydraulic system’s efficiency and reliability.

Role of Part 3008400 Hydraulic Pump Gasket in Engine Systems

The part 3008400 Hydraulic Pump Gasket is integral to the efficient operation of various engine systems by ensuring proper sealing and pressure maintenance. Here’s how it interfaces with several key components:

Sealing the Hydraulic Pump

The gasket is positioned between the hydraulic pump and its mounting surface, providing a tight seal that prevents hydraulic fluid leaks. This seal is essential for maintaining the hydraulic pressure required for the operation of systems like the power steering assembly and vacuum/hydraulic pumps.

Integration with Drive Systems

In engines where hydraulic pump drives are utilized, the gasket ensures that the hydraulic pump remains securely attached to its drive mechanism. This is particularly important in systems involving the front gear train accessory drive and rear gear train accessory drive, where consistent hydraulic pressure is necessary for smooth operation.

Coupling and Accessory Drives

The gasket also plays a role in the gasket coupling 2008 kit and service coupling 2008 assembly, where it ensures that the hydraulic pump is correctly sealed to its coupling. This is vital for the efficient transfer of power to accessories like the turbocharger and fuel pump.

Cylinder and Block Assembly

Within the engine block and around the cylinder arrangement, the hydraulic pump gasket helps in maintaining the integrity of the hydraulic system. This is especially important in high-performance engines where precise hydraulic control is required for components like the vacuum pump and sea water pump.

Rebuild and Repair Kits

When engines undergo maintenance or repair, the 3008400 gasket is often included in rebuild kits and vacuum pump repair kits. Its role in these kits is to ensure that during reassembly, the hydraulic system remains leak-free and operates efficiently.

Accessory and Auxiliary Systems

For engines equipped with auxiliary pumps and other accessory drives, the gasket ensures that the hydraulic pump can deliver consistent pressure. This is crucial for the operation of systems like the sea water pump mounting and the lower engine gasket kit.

Cover and Gear Assemblies

The gasket is also used in conjunction with cover mounting plates and gear covers to ensure that hydraulic fluid does not escape, maintaining the necessary pressure for the efficient functioning of these components.

Conclusion

In summary, the 3008400 Hydraulic Pump Gasket is a fundamental component in ensuring the reliability and efficiency of hydraulic systems across various engine applications. Its role in sealing the hydraulic pump, integrating with drive systems, and supporting accessory and auxiliary systems underscores its importance in maintaining the performance and longevity of commercial truck engines.

-

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.