This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

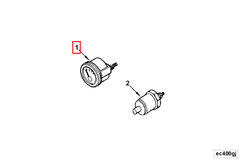

The Cummins 3032800 Pressure Gauge is a specialized instrument designed for use in commercial truck operations. Its purpose is to monitor and display the pressure levels within various systems of a truck, providing vital information that aids in the efficient and safe operation of the vehicle. The significance of this gauge lies in its ability to offer real-time data, which is essential for maintaining optimal performance and preventing potential issues that could arise from pressure discrepancies 1.

Basic Concepts of Pressure Gauges

A pressure gauge is an instrument used to measure the pressure of a fluid relative to the ambient pressure. It operates based on the principle that a change in pressure causes a corresponding change in the physical properties of the fluid, which can be detected and displayed. Pressure gauges typically consist of a dial, a pointer, and a mechanism that translates pressure changes into pointer movements, allowing for easy reading of pressure levels 2.

Role of the 3032800 Pressure Gauge in Truck Operation

The Cummins 3032800 Pressure Gauge plays a specific role in the operation of a commercial truck by monitoring the pressure within critical systems such as the fuel, oil, and air systems. Its integration into the truck’s systems allows for continuous monitoring, ensuring that pressure levels remain within safe and efficient operating ranges. This monitoring is vital for the proper functioning of the engine and other components, as well as for the overall safety and performance of the truck 3.

Key Features

The Cummins 3032800 Pressure Gauge is characterized by several key features that enhance its performance and reliability. Its design incorporates durable materials that withstand the harsh conditions of commercial truck environments. Additionally, the gauge features a clear and easy-to-read display, allowing for quick and accurate pressure readings. Unique attributes such as its calibration accuracy and resistance to vibration further contribute to its effectiveness in demanding applications.

Benefits of Using the 3032800 Pressure Gauge

The advantages provided by the Cummins 3032800 Pressure Gauge include high accuracy in pressure readings, ensuring that operators have precise information for decision-making. Its durability allows it to withstand the rigors of commercial truck use, while its ease of use simplifies the monitoring process. These benefits contribute to safer and more efficient truck operations.

Installation and Integration

To ensure optimal performance, the Cummins 3032800 Pressure Gauge should be installed according to manufacturer guidelines. This involves connecting the gauge to the appropriate system and securing it in a location where it is easily visible to the operator. Proper integration into the truck’s system is crucial for accurate readings and reliable operation.

Troubleshooting Common Issues

Common problems that may arise with the Cummins 3032800 Pressure Gauge include inaccurate readings or gauge malfunctions. Troubleshooting steps may involve checking the connections for leaks or blockages, ensuring the gauge is properly calibrated, and inspecting for physical damage. Addressing these issues promptly can help maintain the gauge’s accuracy and reliability.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and reliable operation of the Cummins 3032800 Pressure Gauge. This includes periodic checks for accuracy, cleaning the gauge to remove any dirt or debris, and inspecting for signs of wear or damage. Adhering to these maintenance tips can help prevent issues and ensure the gauge continues to provide accurate and reliable pressure readings.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial vehicle operators 3.

Integration with Cummins Engines

The Pressure Gauge part 3032800, manufactured by Cummins, is designed to integrate seamlessly with a range of Cummins engines, including the K19, K38, and K50 models. This component is essential for monitoring and maintaining optimal pressure levels within these engines, ensuring efficient operation and longevity.

For the K19 and K38 engines, the Pressure Gauge part 3032800 is engineered to fit precisely into the engine’s pressure monitoring system. Its installation is straightforward, requiring minimal adjustments to the existing setup. The gauge provides real-time data, which is crucial for diagnosing potential issues before they escalate into significant problems.

In the case of the K50 engine, the Pressure Gauge part 3032800 is designed to be compatible with the engine’s advanced pressure management features. This compatibility ensures that the gauge can accurately measure and display pressure readings, allowing for precise adjustments and maintenance. The integration process is seamless, with the gauge being a direct replacement for older or faulty components.

Overall, the Pressure Gauge part 3032800 is a critical component for these Cummins engines, providing essential data for maintaining optimal performance and preventing potential failures.

Role of Part 3032800 Pressure Gauge in Engine Systems

The Part 3032800 Pressure Gauge is an essential component in various engine systems, providing vital data that ensures the engine operates within optimal parameters.

Integration with Engine Instrumentation

When integrated into the engine instrumentation system, the Part 3032800 Pressure Gauge offers real-time monitoring of pressure levels. This data is indispensable for maintaining engine health, as it allows for the early detection of anomalies that could lead to more significant issues if left unaddressed. The gauge’s readings are typically displayed on the engine’s control panel, enabling operators to make informed decisions promptly.

Function within the Electric System Kit

In the context of an electric system kit, the Part 3032800 Pressure Gauge plays a supportive role by ensuring that the electrical components receive consistent pressure levels. This consistency is vital for the reliable operation of sensors, actuators, and other electrical subsystems within the engine. The gauge helps in fine-tuning the system, thereby enhancing overall efficiency and reliability.

Role in Gear Oil Press Gauge Systems

When utilized in conjunction with a gear oil press gauge, the Part 3032800 Pressure Gauge provides precise measurements of oil pressure within the gearbox. This is particularly important for lubrication systems, where maintaining the correct pressure ensures that moving parts are adequately lubricated. Proper lubrication reduces wear and tear, extends the lifespan of gear components, and contributes to the smooth operation of the engine.

Conclusion

In summary, the Cummins 3032800 Pressure Gauge is a versatile component that enhances the functionality and reliability of various engine systems by providing accurate pressure readings. Its integration into commercial truck operations ensures optimal performance, safety, and efficiency.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.