This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4010915 Pressure Gauge is a specialized instrument designed for use in commercial trucks. It serves to monitor and display the pressure levels within various systems of the vehicle, ensuring that operations remain within safe and efficient parameters. This gauge is integral to maintaining the performance and reliability of truck systems, providing operators with vital information that aids in the prevention of potential issues and the optimization of vehicle operation 1.

Basic Concepts of Pressure Gauges

A pressure gauge is an instrument that measures the pressure of gases, liquids, or vapors. It operates based on the principle that pressure applied to a fluid causes a force on the surfaces in contact with that fluid. This force can be measured and displayed as a pressure reading. Pressure gauges typically consist of a dial, a pointer, and a mechanism that translates pressure into a readable format. The Cummins 4010915 Pressure Gauge utilizes these principles to provide accurate pressure readings in truck systems 2.

Purpose of the Cummins 4010915 Pressure Gauge

The Cummins 4010915 Pressure Gauge plays a role in the operation of a truck by monitoring the pressure within specific systems, such as the fuel, air, or hydraulic systems. It provides operators with real-time data that is crucial for maintaining system performance and ensuring safety. By displaying pressure levels, this gauge helps in identifying deviations from normal operating conditions, allowing for timely interventions to prevent system failures or inefficiencies 3.

Key Features

The Cummins 4010915 Pressure Gauge is characterized by several key features that enhance its performance and reliability. Its design incorporates durable materials that withstand the harsh environments typical of commercial truck operations. The gauge is engineered with precision to provide accurate readings, and it includes a clear, easy-to-read display. Additionally, it is constructed to be compatible with a wide range of truck systems, ensuring versatility in its applications.

Benefits

The advantages provided by the Cummins 4010915 Pressure Gauge include improved system monitoring, which leads to enhanced safety and increased efficiency in truck operations. By providing accurate and timely pressure readings, this gauge enables operators to make informed decisions that can prevent system malfunctions and optimize vehicle performance. Its reliability and durability contribute to the overall safety and efficiency of commercial truck operations.

Installation and Usage

Proper installation and usage of the Cummins 4010915 Pressure Gauge are vital for optimal performance. Installation should follow manufacturer guidelines to ensure accurate readings and system compatibility. Usage involves regularly checking the gauge for any signs of wear or malfunction and ensuring it is properly calibrated. Adhering to best practices in installation and usage will help maintain the gauge’s accuracy and longevity.

Troubleshooting and Maintenance

Common issues with the Cummins 4010915 Pressure Gauge may include inaccurate readings or physical damage. Troubleshooting involves checking the gauge for proper installation, ensuring it is correctly calibrated, and inspecting for any visible damage. Maintenance procedures include regular cleaning, calibration checks, and replacing any worn or damaged components. These practices ensure the gauge’s longevity and accurate performance.

Integration with Truck Systems

The Cummins 4010915 Pressure Gauge is designed to integrate seamlessly with various truck systems, offering compatibility with a wide range of makes and models. Its role in comprehensive truck diagnostics is significant, as it provides critical data that aids in the overall assessment and maintenance of vehicle systems. This integration ensures that the gauge contributes effectively to the health and efficiency of the truck it is installed in.

Safety Considerations

When using the Cummins 4010915 Pressure Gauge, it is important to adhere to safety guidelines and precautions. This includes proper handling during installation to avoid damage, ensuring the gauge is securely mounted to prevent accidents, and following operational safety measures to protect both the equipment and the operator. Safety considerations are paramount in maintaining the integrity of the gauge and the safety of the vehicle’s operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and a broad product range, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and performance is evident in its products, including the Cummins 4010915 Pressure Gauge, which exemplifies the brand’s dedication to excellence in automotive and heavy-duty truck parts.

Pressure Gauge Part 4010915 in Cummins Engines

The Pressure Gauge part 4010915, manufactured by Cummins, is a critical component in ensuring the operational integrity and efficiency of the engines. This part is designed to monitor and maintain the pressure levels within the engine systems, providing essential data for optimal performance.

Application in QSV81G and QSV91G Engines

The Pressure Gauge part 4010915 is specifically engineered to fit seamlessly within the QSV81G and QSV91G engines. These engines, known for their robust design and high performance, benefit significantly from the precise pressure monitoring capabilities of this part.

-

QSV81G Engine: The Pressure Gauge part 4010915 is integrated into the QSV81G engine’s system to ensure that the pressure levels remain within the specified operational range. This helps in preventing potential damage due to overpressure or underpressure conditions, thereby extending the engine’s lifespan and maintaining its efficiency.

-

QSV91G Engine: Similarly, in the QSV91G engine, the Pressure Gauge part 4010915 plays a crucial role in monitoring and regulating pressure. Its precise readings are vital for the engine’s control systems to make real-time adjustments, ensuring smooth and efficient operation.

Importance of the Pressure Gauge

The Pressure Gauge part 4010915 is essential for the following reasons:

- Safety: By continuously monitoring pressure levels, it helps in preventing accidents caused by pressure surges.

- Efficiency: Accurate pressure readings ensure that the engine operates at peak efficiency, reducing fuel consumption and wear.

- Maintenance: It provides valuable data for maintenance personnel, enabling them to perform timely interventions and avoid costly breakdowns.

Role of Part 4010915 Pressure Gauge in Engine Systems

The 4010915 Pressure Gauge is an essential component in the engine monitoring system, providing real-time data on the pressure levels within various engine components. This data is vital for maintaining optimal engine performance and ensuring the longevity of the engine.

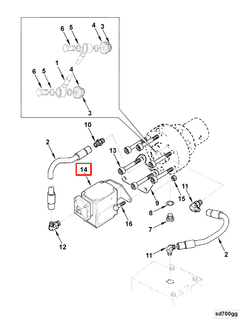

Integration with Engine Monitoring System

When integrated into the engine monitoring system, the 4010915 Pressure Gauge continuously measures and displays the pressure within critical engine components such as the fuel system, lubrication system, and cooling system.

-

Fuel System: The gauge monitors the pressure in the fuel lines, ensuring that the fuel injectors receive the correct pressure for efficient combustion. This helps in maintaining the engine’s power output and fuel efficiency.

-

Lubrication System: By monitoring the oil pressure, the gauge ensures that all moving parts within the engine are properly lubricated. This reduces friction and wear, contributing to the overall reliability of the engine.

-

Cooling System: The gauge also plays a role in monitoring the pressure within the cooling system. Proper pressure ensures efficient heat dissipation, preventing overheating and potential engine damage.

System-Wide Benefits

The data provided by the 4010915 Pressure Gauge allows engineers and mechanics to make informed decisions regarding engine maintenance and performance tuning.

-

Proactive Maintenance: By continuously monitoring pressure levels, potential issues can be identified before they lead to significant problems. This allows for timely interventions, reducing the risk of engine failure.

-

Performance Optimization: The gauge’s data can be used to fine-tune engine parameters, ensuring that the engine operates at peak efficiency under various conditions.

Conclusion

In summary, the Cummins 4010915 Pressure Gauge is a vital component in the QSV81G and QSV91G engines, ensuring that pressure levels are maintained within safe and efficient parameters. Its integration with engine systems provides essential data for maintaining optimal performance and safety, contributing to the overall health and efficiency of commercial truck operations.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.