This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4062833 Sight Gauge is a component designed to facilitate the monitoring of fluid levels within commercial trucks. Its role is integral to ensuring the proper operation and maintenance of the vehicle, providing a clear visual indication of fluid status which is vital for the truck’s performance and longevity 1.

Basic Concepts of Sight Gauges

A sight gauge is a transparent device used in fluid management systems to allow for the visual inspection of fluid levels. It operates by providing a direct line of sight into the system, enabling operators to assess the quantity of fluid present without the need for invasive procedures. This transparency in fluid management is important for maintaining system integrity and ensuring that operations are conducted within safe parameters 2.

Purpose of the Cummins 4062833 Sight Gauge

The Cummins 4062833 Sight Gauge serves a specific function in the operation of a truck by allowing for the continuous monitoring of fluid levels. This monitoring is important for ensuring that the truck operates within optimal conditions, as it enables timely identification of low fluid levels which could lead to system failures if not addressed promptly 3.

Key Features

The Cummins 4062833 Sight Gauge is characterized by its robust design and the use of high-quality materials that ensure durability and reliability. Its transparent construction allows for clear visibility of fluid levels, and it may include features such as graduated markings for precise level indication and secure mounting options to ensure stability during operation.

Benefits of Using the Cummins 4062833 Sight Gauge

Incorporating the Cummins 4062833 Sight Gauge into truck maintenance routines offers several advantages. It contributes to improved efficiency by allowing for quick assessments of fluid levels, enhances safety by providing early warnings of potential issues, and increases reliability by ensuring that the truck operates with the correct fluid levels at all times.

Installation and Integration

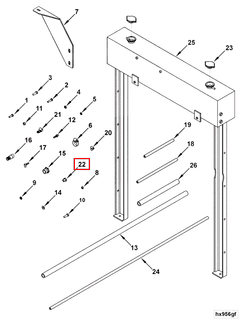

To ensure optimal performance and compatibility, the Cummins 4062833 Sight Gauge should be installed according to manufacturer guidelines. This involves securing the gauge in the appropriate location within the truck’s fluid system, ensuring that it is properly aligned and sealed to prevent leaks and provide accurate readings.

Troubleshooting and Maintenance

Common issues with the Cummins 4062833 Sight Gauge may include inaccurate readings or leaks. Troubleshooting these issues involves checking the gauge for proper alignment and seals, and ensuring that the fluid system is operating correctly. Regular maintenance practices, such as cleaning the gauge and inspecting for wear or damage, can help prolong its lifespan and ensure continued accurate operation.

Safety Considerations

When working with the Cummins 4062833 Sight Gauge, it is important to observe safety guidelines to protect personnel and maintain the integrity of the equipment. This includes ensuring that the truck is turned off and the fluid system is depressurized before attempting any maintenance or adjustments to the gauge.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for producing high-quality components that contribute to the efficiency, safety, and reliability of commercial vehicles.

Cummins Sight Gauge 4062833 Compatibility

The Cummins Sight Gauge part number 4062833 is designed to facilitate the inspection and maintenance of various Cummins engines. This part is engineered to fit seamlessly into the engine systems of the G8.3, G855, and N14 G engines, ensuring that users can effectively monitor and manage their engine’s operational parameters.

In the G8.3 and G855 engines, the sight gauge is strategically positioned to provide clear visibility of the engine’s fluid levels. This is particularly important for maintaining the proper oil and coolant levels, which are essential for the engine’s longevity and performance. The sight gauge’s design allows for easy and accurate readings, helping to prevent potential engine damage due to fluid mismanagement.

For the N14 G engine, the sight gauge serves a similar purpose but is tailored to the specific design and requirements of this engine model. The N14 G, known for its robust performance and reliability, benefits from the precise fluid level monitoring that the sight gauge provides. This ensures that the engine operates within optimal parameters, contributing to its overall efficiency and durability.

By integrating the Cummins Sight Gauge 4062833 into these engines, users can confidently monitor fluid levels, ensuring that their engines remain in top condition. This part’s compatibility with the G8.3, G855, and N14 G engines underscores Cummins’ commitment to providing high-quality, reliable components that enhance engine performance and maintenance.

Role of Part 4062833 Sight Gauge in Engine Systems

The Part 4062833 Sight Gauge is an essential component in monitoring and maintaining the operational integrity of various engine systems. It is strategically integrated into systems involving heat exchangers, expansion tanks, and other fluid-based components to provide real-time visual feedback on the system’s status.

Integration with Heat Exchangers

In heat exchanger systems, the Sight Gauge is installed along the fluid pathways. It allows engineers and mechanics to visually inspect the flow and level of coolant or other fluids. This visual confirmation helps in identifying potential issues such as air pockets, blockages, or leaks that could impair the heat exchanger’s efficiency. Regular monitoring via the Sight Gauge ensures that the heat transfer process remains optimal, preventing overheating and maintaining engine performance.

Functionality in Expansion Tanks

When integrated into expansion tanks, the Sight Gauge plays a significant role in maintaining the correct fluid levels. Expansion tanks are designed to accommodate the changes in fluid volume due to temperature fluctuations. The Sight Gauge provides a clear view of the fluid level, enabling timely top-ups or bleeds as necessary. This prevents the tank from either overfilling, which could lead to pressure build-up, or underfilling, which might cause the engine to run hot. Consistent fluid level management is key to prolonging the lifespan of the expansion tank and ensuring stable engine operation.

Overall System Monitoring

Beyond specific components like heat exchangers and expansion tanks, the Sight Gauge contributes to the overall health monitoring of engine systems. It offers a straightforward, non-intrusive method for engineers to assess the condition of fluid-based systems. By providing immediate visual data, it aids in the early detection of anomalies, facilitating prompt corrective actions and reducing the risk of more severe engine issues.

Conclusion

In summary, the Part 4062833 Sight Gauge is a valuable tool in the maintenance and operation of engine systems, offering essential insights into the fluid dynamics within critical components. Its integration into various engine systems enhances the monitoring capabilities, ensuring optimal performance and longevity of the engines.

-

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023

↩ -

Design and Development of Heavy Duty Diesel Engines: A Handbook, P. A. Lakshminarayanan and Avinash Kumar, Springer Nature, 2020

↩ -

Heavyduty Electric Vehicles: From Concept to Reality, Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Elsevier, 2021

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.