This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4071825 Pressure Gauge is a specialized instrument designed for use in commercial trucks. Its purpose is to monitor and display the pressure levels within various systems of the truck, ensuring that operations remain within safe and efficient parameters. The significance of this gauge lies in its ability to provide real-time data that aids in the maintenance and operational efficiency of the vehicle .

Basic Concepts of Pressure Gauges

A pressure gauge is an instrument used to measure the pressure of a fluid relative to the ambient pressure. It operates based on the principle that a change in pressure causes a corresponding change in the physical properties of the gauge’s sensing element, such as its shape or position. This change is then translated into a readable measurement, typically displayed on a dial or digital screen. The fundamental principles behind its functionality include the use of mechanical, electrical, or digital components to detect and display pressure changes accurately .

Role of the 4071825 Pressure Gauge in Truck Operation

The Cummins 4071825 Pressure Gauge plays a specific role in the operation of a commercial truck by monitoring the pressure levels in critical systems such as the fuel, hydraulic, and pneumatic systems. Its integration into the truck’s systems allows for continuous monitoring, which helps in identifying potential issues before they escalate into more significant problems. This gauge ensures that the truck operates within the manufacturer’s specified pressure ranges, contributing to the overall efficiency and safety of the vehicle .

Key Features

The Cummins 4071825 Pressure Gauge is characterized by several key features that enhance its functionality and durability. These include a robust design that can withstand the harsh environments typical of commercial trucking, the use of high-quality materials to ensure longevity, and a clear, easy-to-read display. Additionally, the gauge may feature unique characteristics such as shock resistance and the ability to operate across a wide temperature range, making it suitable for various operational conditions.

Benefits of Using the 4071825 Pressure Gauge

The advantages provided by the Cummins 4071825 Pressure Gauge include high accuracy in pressure readings, which is crucial for maintaining system efficiency and safety. Its durability ensures long-term use without the need for frequent replacements, and its ease of use allows for straightforward installation and operation. These benefits contribute to the overall reliability and performance of the truck’s systems.

Installation and Integration

Proper installation and integration of the 4071825 Pressure Gauge into a truck’s system involve several steps. It is important to ensure that the gauge is compatible with the specific system it will monitor. Installation should follow the manufacturer’s guidelines, including any necessary preparations such as cleaning the installation site and ensuring that all connections are secure. Integration into the truck’s systems may require calibration to ensure accurate readings.

Troubleshooting Common Issues

Common problems that may arise with the 4071825 Pressure Gauge include inaccurate readings, gauge malfunction, or physical damage. Troubleshooting steps may involve checking the gauge’s connections, calibrating the instrument, or inspecting it for physical damage. In some cases, replacing the gauge or seeking professional assistance may be necessary to resolve the issue.

Maintenance Tips

Regular maintenance practices for the Cummins 4071825 Pressure Gauge include periodic checks for accuracy, cleaning the gauge to remove any dirt or debris, and inspecting it for signs of wear or damage. Following these maintenance tips can help ensure the longevity and optimal performance of the gauge, contributing to the overall efficiency and safety of the truck’s operations.

Safety Considerations

When working with the 4071825 Pressure Gauge, it is important to observe several safety guidelines and precautions. These include ensuring that the truck’s engine is off and the system is depressurized before attempting any maintenance or installation work. Wearing appropriate personal protective equipment (PPE) and following all manufacturer’s safety instructions can help prevent accidents and ensure safe operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the industry, Cummins is committed to quality and excellence. The company’s products are known for their reliability, efficiency, and performance, making them a preferred choice for commercial and industrial applications worldwide.

Role of Part 4071825 Pressure Gauge in Engine Systems

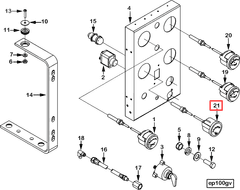

The Part 4071825 Pressure Gauge is an integral component in various engine systems, providing essential data for the efficient and safe operation of the engine. Here’s how it integrates with the provided components:

-

Accessories Install Panel: The Pressure Gauge is often mounted on the accessories install panel, allowing for easy access and monitoring by the operator. This panel typically houses various gauges and controls, making it a central point for engine monitoring.

-

Engine Installation Kit: Included in the engine installation kit, the Pressure Gauge ensures that from the outset, the engine is equipped with necessary monitoring tools. This kit often contains all required components for a complete engine setup, including mounting brackets and wiring harnesses for the gauge.

-

Engine Instrumentation: As part of the engine instrumentation, the Pressure Gauge works alongside other instruments to provide a comprehensive view of engine performance. It specifically measures oil pressure, which is vital for assessing the lubrication system’s health.

-

Gauge: The Pressure Gauge is a specific type of gauge designed to measure and display oil pressure within the engine. It is calibrated to provide accurate readings, ensuring that the engine operates within safe parameters.

-

Oil Pressure Instrument: Directly related to the oil pressure instrument, the Pressure Gauge offers real-time data on the oil pressure levels. This information is critical for diagnosing potential issues with the oil pump or filtration system.

-

Instrument and Gauges Box: Housed within the instrument and gauges box, the Pressure Gauge is protected from environmental factors while still providing clear readings. This box often includes other gauges and instruments, creating a centralized monitoring station.

-

Instrument Panel: Mounted on the instrument panel, the Pressure Gauge is easily visible to the operator. This panel is typically located in the engine room or cockpit, ensuring that all vital engine parameters are within reach for quick assessment.

-

Instrumentation Kit: Part of the instrumentation kit, the Pressure Gauge is essential for comprehensive engine monitoring. This kit usually includes a variety of gauges and sensors, all working together to provide a full picture of engine health.

-

Junction Box Panel: Connected to the junction box panel, the Pressure Gauge receives power and sends data to other systems. This panel acts as a distribution point for electrical connections, ensuring that all instruments are properly powered and communicating.

-

Kit On Board Spares: Often included in the kit on board spares, the Pressure Gauge ensures that replacement parts are readily available. This is important for maintaining engine reliability during long operations or remote locations.

-

Mounting Gauges: Specifically designed for mounting gauges, the Pressure Gauge fits into standardized mounting points. This ensures a secure and stable installation, reducing the risk of damage or inaccurate readings.

-

Mounting Instrument Panel: The Pressure Gauge is mounted on the instrument panel, providing a clear and accessible display for the operator. This panel is designed to hold multiple instruments, making it a focal point for engine monitoring.

-

MTG (Mounting): The Pressure Gauge is often referred to by its MTG code, indicating its specific mounting requirements and compatibility with other gauges.

-

Amot Safety Control: Integrated with the Amot safety control system, the Pressure Gauge helps in monitoring parameters that are crucial for safety. This system often includes automated responses to abnormal readings, enhancing overall engine safety.

-

Panel: The Pressure Gauge is installed on the panel, which may be part of the engine instrument system. This panel provides a structured and organized layout for all gauges and controls.

-

Engine Instrument: As an engine instrument, the Pressure Gauge is essential for monitoring specific parameters that indicate the engine’s condition. It provides data that can be used for both routine monitoring and diagnostic purposes.

-

System: Within the engine monitoring system, the Pressure Gauge plays a role in ensuring that all components are functioning correctly. This system often includes multiple gauges and sensors, all working together to provide a comprehensive view of engine health.

-

Engine Monitoring: Finally, the Pressure Gauge is a key component in the engine monitoring process. It provides real-time data on oil pressure, which is essential for maintaining engine performance and preventing potential failures.

Conclusion

The Cummins 4071825 Pressure Gauge is a vital component in the operation and maintenance of commercial trucks and various engine systems. Its role in monitoring pressure levels ensures the efficient and safe operation of the vehicle, contributing to its overall reliability and performance. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

: Gifford, Clive. *Cars Encyclopedia*. DK Publishing, 2014.

: Awari, G.K., Kumbhar, V.S., and Tirpude, R.B. *Automotive Systems Principles and Practice*. CRC Press, 2011.

: Cummins Inc. *Owners Manual for QSF2.8 CM2880 F131*, Bulletin Number 5411491.RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.