This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

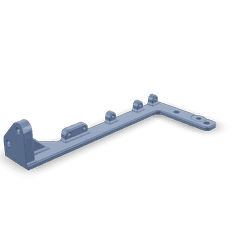

The Gear Housing Brace 3100196, designed by Cummins, is a component aimed at enhancing the structural integrity of heavy-duty truck transmissions. It provides additional support to the gear housing, ensuring stability and reliability under demanding operational conditions.

Basic Concepts

Gear housing braces are vital to the drivetrain system, offering reinforcement to the gear housing. This reinforcement helps maintain the alignment and stability of transmission components, contributing to the overall performance and longevity of the truck. By distributing stress more evenly across the gear housing, these braces help reduce the likelihood of deformation or failure under heavy loads 1.

Purpose and Role

This Cummins part is specifically engineered to support the gear housing in heavy-duty truck transmissions. It enhances the durability and reliability of the transmission system by providing additional structural support. This support is particularly important in applications where the transmission is subjected to high torque and stress, ensuring that the gear housing remains stable and aligned 2.

Key Features

The Gear Housing Brace 3100196 features a robust design tailored to fit precisely within the transmission system. It is constructed from high-strength materials to withstand the rigors of heavy-duty use. Unique attributes of this brace include its precise engineering to ensure a perfect fit and its ability to handle significant stress without compromising integrity 3.

Benefits

Utilizing the Gear Housing Brace 3100196 offers several advantages. It improves the structural integrity of the transmission system by providing additional support to the gear housing. This reinforcement reduces stress on the gear housing, leading to enhanced durability and reliability. Additionally, the brace contributes to the overall performance of the truck’s transmission system by ensuring that components remain properly aligned and stable under load 4.

Installation Process

Installing the Gear Housing Brace 3100196 requires careful attention to detail to ensure proper fitment and functionality. The process involves accessing the gear housing, aligning the brace with the designated mounting points, and securing it in place using the appropriate fasteners. It is important to follow the manufacturer’s guidelines to ensure a successful installation, including using the recommended tools and taking necessary precautions to avoid damage to surrounding components.

Troubleshooting and Maintenance

Regular inspection and maintenance of the Gear Housing Brace 3100196 are recommended to ensure its continued effectiveness. Common issues may include loosening of fasteners or signs of wear and stress. Addressing these issues promptly can help prolong the lifespan of the brace and maintain optimal performance. Maintenance tips include checking for proper alignment, ensuring fasteners are secure, and inspecting for any signs of damage or wear.

Common Failure Modes

Gear housing braces can experience failure due to various factors, including excessive stress, improper installation, or material fatigue. Symptoms of failure may include unusual noises, misalignment of transmission components, or visible damage to the brace. Preventive measures include regular inspections, proper installation practices, and addressing any signs of wear or stress promptly to mitigate the risk of failure.

Upgrades and Modifications

While the Gear Housing Brace 3100196 is designed for specific applications, there may be opportunities for upgrades or modifications to enhance its performance or adapt it to unique operating conditions. These could include material upgrades for increased strength or custom modifications to fit non-standard transmissions. It is important to consult with a professional to ensure any modifications are compatible and do not compromise the integrity of the transmission system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company offers a wide range of products designed to meet the demanding needs of various applications, ensuring reliability and performance in critical operations.

Role of Part 3100196 Gear Housing Brace in Engine Systems

The 3100196 Gear Housing Brace is an integral component in the structural integrity of engine systems, particularly in relation to the block and cylinder components.

In the context of the engine block, the Gear Housing Brace provides additional support and stability to the gear housing. This is essential as the engine block is the foundational structure of the engine, housing the cylinders, pistons, and other critical components. The brace helps in distributing the mechanical stresses generated during engine operation, thereby enhancing the durability and reliability of the block.

Regarding the cylinder, the Gear Housing Brace plays a supportive role in maintaining the alignment and stability of the gear housing in relation to the cylinder. This is particularly important in engines where the cylinder and gear housing are in close proximity or directly interact. The brace ensures that the gear housing remains securely in place, which is vital for the smooth operation of the valve train and other moving parts within the cylinder.

Overall, the 3100196 Gear Housing Brace contributes to the efficient and reliable functioning of the engine by providing necessary structural support to both the engine block and the cylinder.

Conclusion

The Gear Housing Brace 3100196 by Cummins is a critical component for enhancing the structural integrity and reliability of heavy-duty truck transmissions. Its robust design, precise engineering, and high-strength materials ensure it can withstand the rigors of heavy-duty use. Regular maintenance and proper installation are essential to maximize its benefits and ensure the longevity and performance of the transmission system.

-

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Rajamani, R. (2005). Vehicle Dynamics and Control. Springer.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.