This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

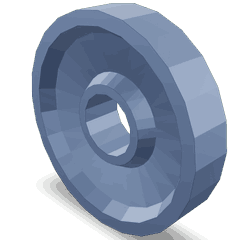

The Cummins 3420715 Idler Gear is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Idler Gears

An idler gear is a type of gear used in gear systems to transmit motion between two non-adjacent gears. It does not directly contribute to the power transmission but rather helps in maintaining the proper alignment and spacing between gears. Idler gears are commonly employed in mechanical systems to change the direction of rotation or to provide additional support and stability to the gear train 1.

Purpose of the Cummins 3420715 Idler Gear

The Cummins 3420715 Idler Gear plays a role in the truck’s drivetrain by ensuring the correct meshing of gears. It helps in maintaining the alignment and spacing between the main drive gears, which is crucial for smooth operation and efficient power transmission. By facilitating proper gear engagement, this idler gear contributes to the overall performance and durability of the truck’s drivetrain system 2.

Key Features

The Cummins 3420715 Idler Gear is designed with several features that enhance its performance and durability. These include precision machining for accurate gear meshing, high-quality materials for resistance to wear and corrosion, and a robust construction that can withstand the demanding conditions of commercial truck operations. These features collectively contribute to the reliability and longevity of the idler gear 3.

Benefits of Using the Cummins 3420715 Idler Gear

Utilizing the Cummins 3420715 Idler Gear offers several advantages. It improves the efficiency of the drivetrain by ensuring optimal gear alignment and engagement. The gear’s durable construction and high-quality materials contribute to its reliability, reducing the likelihood of unexpected failures. Additionally, its design helps in prolonging the lifespan of the truck’s drivetrain components by minimizing wear and stress on the system 4.

Installation Considerations

Proper installation of the Cummins 3420715 Idler Gear is vital for ensuring optimal performance and longevity. It is important to follow manufacturer guidelines for installation, which may include checking for proper alignment, ensuring all mating surfaces are clean and free of debris, and using the correct torque specifications for fastening components. Adhering to these best practices helps in achieving the desired performance and durability from the idler gear.

Troubleshooting Common Issues

Common problems associated with idler gears can include noise, vibration, or abnormal wear. These issues may arise from improper installation, misalignment, or wear and tear over time. Troubleshooting steps may involve inspecting the gear for signs of damage or wear, checking the alignment of the gear within the system, and ensuring that all components are properly lubricated. Addressing these issues promptly can help in maintaining the efficiency and reliability of the truck’s drivetrain.

Maintenance Tips

Routine maintenance practices are important for prolonging the life of the Cummins 3420715 Idler Gear and ensuring continued reliable operation. This may include regular inspection for signs of wear or damage, ensuring proper lubrication, and checking for correct alignment within the gear system. Adhering to a scheduled maintenance plan can help in identifying potential issues before they lead to more significant problems, thereby enhancing the overall performance and longevity of the truck’s drivetrain.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications.

Cummins Idler Gear 3420715 Compatibility

The Cummins Idler Gear part number 3420715 is designed to fit seamlessly within a range of engine models, ensuring smooth operation and longevity. This component is crucial for maintaining the proper functioning of the engine’s timing mechanism.

Compatible Engines

-

QSV81G and QSV91G: These engines benefit from the precision engineering of the 3420715 Idler Gear, which helps in maintaining the timing belt’s alignment and reducing wear on other components.

-

QSW/QSV82: The 3420715 Idler Gear is engineered to fit these models, providing the necessary support for the timing belt and ensuring that the engine runs efficiently.

-

QSW27 and QSW36: These engines also utilize the 3420715 Idler Gear, which is designed to handle the specific demands of these models, contributing to the overall reliability and performance of the engine.

-

QSW73: This engine model is another beneficiary of the 3420715 Idler Gear, which is crafted to meet the precise specifications required for optimal engine function.

By ensuring that the 3420715 Idler Gear is correctly installed, engine owners can expect improved performance and longevity from their engines.

Role of Part 3420715 Idler Gear in Engine Systems

The Part 3420715 Idler Gear is an integral component within various engine systems, facilitating the smooth operation of multiple assemblies and mechanisms.

In the Assembly Housing Gear, the idler gear ensures that the rotational forces are correctly transmitted and balanced, preventing undue stress on the primary drive components. This balance is essential for the longevity and efficiency of the gear assembly.

Within the Cam and Assy L8+V16, the idler gear plays a significant role in maintaining the timing and synchronization of the camshaft operations. By providing a consistent and reliable transfer of motion, it helps in optimizing the valve timing, which is fundamental for engine performance.

In CCW (Counterclockwise) Camshaft Drives, the idler gear is employed to reverse the direction of rotation where necessary. This reversal is vital for the proper functioning of the camshaft, ensuring that the valves open and close at the correct intervals.

For the Accessory Drive systems, particularly those involving the Front Gear Train Accessory, the idler gear aids in distributing drive power to various engine accessories such as the alternator, water pump, and power steering pump. This distribution ensures that each accessory receives the necessary power without overloading the primary drive shaft.

In Heat Exchanger systems, the idler gear is used within the Gear Assembly Housing to manage the rotation of the heat exchanger components. This management is key to maintaining efficient heat transfer and preventing overheating of engine components.

Lastly, in the Idler Assembly Gear, the part 3420715 Idler Gear serves as a pivotal point for tensioning and guiding the timing belt or chain. This function is essential for maintaining the correct tension, which is critical for the reliable operation of the timing system and the overall engine performance.

Conclusion

The Cummins 3420715 Idler Gear is a critical component in the drivetrain of commercial trucks, ensuring the proper alignment and spacing of gears for efficient power transmission. Its precision machining, high-quality materials, and robust construction contribute to the reliability and longevity of the truck’s drivetrain system. Proper installation, maintenance, and troubleshooting are essential for maximizing the performance and lifespan of this Cummins part.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Ling, F. F. (2011). The Automotive Body. Springer Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.