This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Gear Cooling Nozzle Body, identified by the part number 3421043, is a component manufactured by Cummins, a reputable entity in the automotive industry renowned for its high-quality engine components. This part is essential for the cooling systems of heavy-duty truck engines, contributing to efficient operation and extended engine life.

Function and Operation

This Cummins part operates within the engine cooling system by directing coolant flow to critical components. It is engineered to spray coolant onto the gear teeth and other high-wear areas within the engine, aiding in heat dissipation and reducing the risk of overheating. This targeted coolant distribution is crucial for maintaining consistent temperatures across the engine, which is vital for optimal performance and durability 1.

Purpose of the Gear Cooling Nozzle Body

The primary function of the Gear Cooling Nozzle Body in a truck’s engine is to maintain optimal engine temperature and performance. By ensuring that coolant is effectively directed to areas prone to high temperatures and wear, it helps preserve the integrity of engine components, thereby enhancing overall engine efficiency and reliability 2.

Key Features

The Gear Cooling Nozzle Body 3421043 is characterized by several design elements and materials that enhance its functionality. It is constructed from durable materials to withstand the high pressures and temperatures within the engine cooling system. Its design includes precise nozzles that ensure an even and effective spray pattern, maximizing coolant coverage on critical engine parts.

Benefits

The advantages provided by the Gear Cooling Nozzle Body include improved engine efficiency through effective heat management, reduced wear on components due to consistent cooling, and enhanced overall reliability of the engine. These benefits contribute to the longevity and performance of the engine, making it a valuable component in heavy-duty truck applications 3.

Installation and Integration

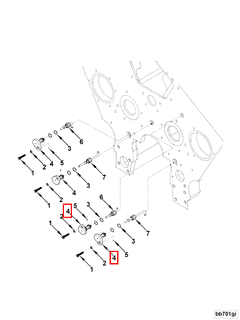

Installation of the Gear Cooling Nozzle Body into the engine cooling system requires careful attention to ensure proper fit and function. It is important to follow manufacturer guidelines for installation, which may include specific torque settings for fasteners and ensuring that all connections are secure and leak-free. Proper integration is key to achieving the intended cooling performance and engine protection.

Maintenance and Troubleshooting

Maintaining the Gear Cooling Nozzle Body involves regular inspection procedures to ensure it remains in optimal condition. Common issues to watch for include blockages in the nozzles, which can impede coolant flow, and signs of wear or corrosion. Troubleshooting tips may include cleaning the nozzles, checking for leaks, and ensuring that the coolant system is free of contaminants that could affect performance.

Manufacturer - Cummins

Cummins has a long-standing reputation in the automotive industry for producing high-quality engine components. With a history of innovation and commitment to excellence, Cummins is recognized for its reliable and durable products. The company’s dedication to quality and performance is evident in the design and manufacturing of the Gear Cooling Nozzle Body 3421043, reinforcing its position as a leader in the industry.

Conclusion

The Gear Cooling Nozzle Body 3421043 plays a significant role in the cooling systems of heavy-duty truck engines. Its design and functionality contribute to maintaining optimal engine temperature, enhancing engine efficiency, and ensuring the longevity of engine components. Proper installation, maintenance, and understanding of its operation are crucial for maximizing the benefits of this Cummins part.

-

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Reif, K. Ed. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.