This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Gear Cooling Nozzle 3421253, a component manufactured by Cummins, plays a crucial role in the engine’s cooling system. Cummins, a prominent figure in the automotive industry, is renowned for its heavy-duty truck engines. This nozzle is essential for maintaining optimal temperature ranges for gear components.

Function and Operation

The Gear Cooling Nozzle 3421253 directs cooling fluid to targeted areas within the engine. It is positioned to spray coolant onto gear components, which experience high friction and heat during operation. This consistent coolant flow helps dissipate heat, stabilizing the temperature of these critical components 1.

Purpose of the Gear Cooling Nozzle

The primary function of the Gear Cooling Nozzle is to maintain optimal operating temperatures for gear components within the engine. This ensures reduced wear and tear on the gears, contributing to prolonged engine life and improved performance 2.

Key Features

The Gear Cooling Nozzle 3421253 is constructed from durable materials capable of withstanding high pressures and temperatures. Its design ensures precise coolant distribution, maximizing cooling efficiency. The robust construction allows it to endure the demands of heavy-duty truck operations 3.

Benefits of Using the Gear Cooling Nozzle

Using the Gear Cooling Nozzle 3421253 offers several advantages. It enhances engine efficiency by ensuring gear components operate at optimal temperatures, leading to improved overall engine performance. Additionally, it reduces thermal stress on gear components, prolonging their lifespan and resulting in lower maintenance costs and increased engine reliability.

Installation and Compatibility

Proper installation of the Gear Cooling Nozzle is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it functions correctly within the engine system. Compatibility with various engine models and configurations is important, ensuring the nozzle can be used across a range of applications without requiring significant modifications.

Maintenance and Troubleshooting

Routine maintenance of the Gear Cooling Nozzle involves regular inspection for signs of wear or damage, cleaning to remove any buildup that could impede coolant flow, and replacement when necessary. Troubleshooting common issues may involve checking for blockages in the coolant passages, ensuring the nozzle is securely installed, and verifying that the coolant system is operating correctly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation and quality in the automotive industry. The company offers a wide range of products designed to meet the needs of various industries, including heavy-duty trucking, where reliability and performance are paramount.

Compatibility with Cummins Engines

The Gear Cooling Nozzle, identified by part number 3421253, is designed to enhance the cooling efficiency of the gear system in various Cummins engines. This part is engineered to fit seamlessly within the specified engine models, ensuring optimal performance and longevity.

Compatible Engines

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

- QSW27

- QSW36

- QSW73

Grouping of Compatible Engines

The Gear Cooling Nozzle is compatible with a range of Cummins engines, which can be grouped based on their model series and specifications:

-

QSV Series

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

-

QSW Series

- QSW/QSV82

- QSW27

- QSW36

- QSW73

This part is meticulously designed to meet the cooling requirements of these engines, ensuring that the gear system operates within its optimal temperature range. The compatibility across these models underscores the versatility and reliability of the Gear Cooling Nozzle in enhancing engine performance.

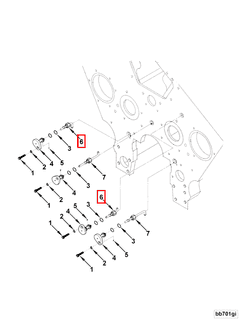

Role of Part 3421253 Gear Cooling Nozzle in Engine Systems

The Gear Cooling Nozzle (Part 3421253) is an integral component in the thermal management system of various engine configurations, including the QSV and D67 engines. Its primary function is to direct a stream of engine oil onto the gear teeth within the cylinder assembly block to mitigate heat buildup and enhance lubrication.

Integration with Key Components

-

Cylinder Block and Assembly: The nozzle is strategically positioned within the cylinder block to ensure that the gear teeth, which are part of the cylinder assembly, receive a consistent flow of cooling oil. This helps in maintaining optimal operating temperatures and reducing wear.

-

Oil Assembly Cooler: The cooling oil supplied to the nozzle typically passes through an oil assembly cooler before reaching the nozzle. This pre-cooled oil enhances the efficiency of the cooling process, ensuring that the gear teeth are not only lubricated but also effectively cooled.

-

Prechamber Bits: In engines with prechamber ignition systems, the efficient operation of prechamber bits is reliant on the overall thermal stability of the engine. The Gear Cooling Nozzle contributes to this stability by preventing excessive heat accumulation in the gear areas, which could otherwise affect the performance of the prechamber bits.

-

Engine Oil Circulation: The nozzle is part of a broader engine oil circulation system that includes the cooler. The oil, after cooling the gears, re-enters the sump, where it is recirculated, thus maintaining a closed-loop system that ensures continuous cooling and lubrication.

-

Block and Cylinder Interaction: The effective placement of the Gear Cooling Nozzle within the block ensures that the oil spray pattern covers the critical areas of the gears. This interaction between the nozzle and the block is designed to maximize cooling efficiency while minimizing oil consumption.

Conclusion

In summary, the Gear Cooling Nozzle (Part 3421253) plays a significant role in the thermal management of engine systems by ensuring that gear teeth remain cool and well-lubricated, thereby contributing to the overall reliability and performance of the engine.

-

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.