This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3690640 Idler Gear is a component designed for use in heavy-duty trucks. It serves a specific function within the vehicle’s gear system, contributing to the efficient operation and performance of the truck. Understanding its role and significance is important for maintaining the vehicle’s overall functionality.

Basic Concepts of Idler Gears

An idler gear is a type of gear used in gear systems to transmit motion between two non-adjacent gears. It does not directly contribute to the output torque but instead alters the direction of rotational forces, allowing for more complex gear arrangements. Idler gears are crucial in maintaining the proper mesh and alignment between driving and driven gears, ensuring smooth and efficient power transmission 1.

Purpose of the 3690640 Idler Gear

The Cummins 3690640 Idler Gear is specifically designed to fit within the gear train of heavy-duty trucks. Its primary function is to ensure proper alignment and meshing between the driving and driven gears. By doing so, it helps in maintaining the efficiency of the gear system and contributes to the overall performance of the truck. This idler gear plays a role in facilitating the transmission of power through the gear system, ensuring that rotational forces are correctly directed and managed 2.

Key Features

The Cummins 3690640 Idler Gear is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design specifications of this idler gear are tailored to meet the demanding requirements of heavy-duty applications, providing reliable operation under various conditions. Additionally, it may include unique attributes such as precision machining and heat treatment processes that further improve its performance 3.

Benefits

The use of the Cummins 3690640 Idler Gear offers several advantages. It contributes to improved efficiency within the gear system by ensuring proper alignment and meshing of gears. This results in reduced wear on other components, extending their lifespan. Additionally, the enhanced reliability of the gear system leads to more consistent performance and fewer unexpected failures, which is particularly important in heavy-duty truck applications.

Installation and Integration

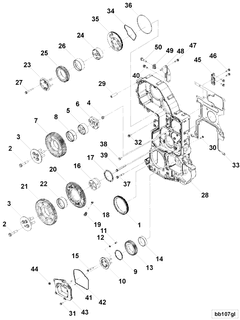

Installing the Cummins 3690640 Idler Gear involves several steps and considerations to ensure proper integration within the truck’s gear system. Preparations may include cleaning the gear housing and inspecting other components for wear or damage. Adjustments might be necessary to achieve the correct mesh and alignment between gears. Following manufacturer guidelines during installation is important to ensure optimal performance and longevity of the idler gear.

Troubleshooting Common Issues

Typical problems that may arise with the Cummins 3690640 Idler Gear include noise, vibration, or abnormal wear. These issues can often be traced back to improper installation, misalignment, or wear on mating gears. Diagnostic procedures may involve inspecting the gear for signs of wear, checking alignment, and ensuring that all components are properly lubricated. Solutions can range from realigning gears to replacing worn components.

Maintenance Practices

Recommended maintenance routines for the Cummins 3690640 Idler Gear include regular inspection intervals to check for signs of wear or damage. Lubrication requirements should be adhered to, ensuring that the gear system remains well-lubricated to reduce friction and wear. Guidelines for identifying and addressing potential issues before they lead to failure are important for maintaining the reliability and performance of the gear system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation within the automotive and heavy-duty truck industries. The company’s product range includes a variety of engines, components, and systems designed to meet the needs of various applications, demonstrating a commitment to innovation, quality, and customer satisfaction.

Idler Gear 3690640 Compatibility with Cummins Engines

The Idler Gear part number 3690640, manufactured by Cummins, is designed to fit a variety of their engine models. This part plays a crucial role in the engine’s operation by ensuring the proper alignment and function of the timing system.

ISX15 Series

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

These ISX15 engines benefit from the 3690640 Idler Gear, which helps maintain the synchronization of the engine’s internal components, ensuring smooth and efficient operation.

QSX15 Series

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX15 engines also utilize the 3690640 Idler Gear. This part is integral to the timing mechanism, helping to reduce wear and tear on other components by ensuring the gears and chains operate smoothly.

X15 Series

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

The X15 series engines incorporate the 3690640 Idler Gear to maintain the precise timing needed for optimal performance. This part is essential in these engines, as it helps to keep the timing system in check, contributing to the engine’s longevity and reliability.

Role of Part 3690640 Idler Gear in Engine Systems

The idler gear, specifically part 3690640, is an essential component in the timing system of an engine. It is strategically positioned to maintain proper tension and alignment of the timing belt or chain, ensuring smooth and efficient operation of the engine’s moving parts.

Interaction with the Cylinder Block

Within the cylinder block, the idler gear works in conjunction with the camshaft and crankshaft to synchronize the opening and closing of the engine’s valves. By maintaining the correct tension on the timing belt or chain, the idler gear ensures that the camshaft and crankshaft rotate in perfect harmony. This synchronization is vital for the precise timing of fuel injection and ignition, directly influencing the engine’s performance and efficiency.

Ensuring Smooth Operation

The idler gear’s role extends beyond simple tension maintenance. It also helps in reducing wear and tear on the timing belt or chain by ensuring even distribution of load. This even distribution prevents premature failure of the timing components, contributing to the longevity and reliability of the engine.

Contribution to Engine Efficiency

By keeping the timing belt or chain properly aligned and tensioned, the idler gear indirectly contributes to the engine’s overall efficiency. Proper timing ensures that the valves open and close at the correct moments, optimizing the air-fuel mixture’s combustion. This optimization leads to better fuel economy and reduced emissions, making the idler gear a key player in modern engine design.

Conclusion

In summary, the Cummins 3690640 Idler Gear is integral to the timing system, working seamlessly with the cylinder block to ensure the engine operates efficiently and reliably. Its role in maintaining proper tension and alignment of the timing belt or chain is crucial for the synchronization of engine components, contributing to the overall performance and longevity of heavy-duty truck engines.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Bonnick, Allan, and Derek Newbold. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩ -

Hilgers, Michael, and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.